Electrochemical measurement-based method and device for measuring thickness of copper wire plating

A coating thickness, electrochemical technology, applied in the direction of measuring devices, instruments, etc., can solve the problem that small cylindrical metal wires cannot be measured, and achieve the effect of improving efficiency, improving efficiency and precision, and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

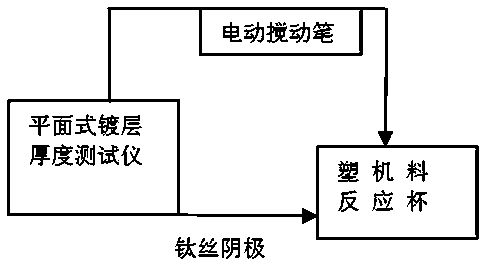

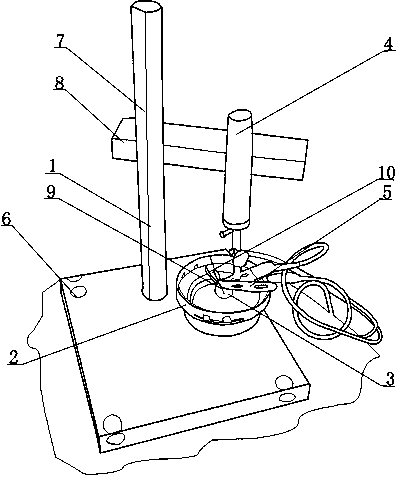

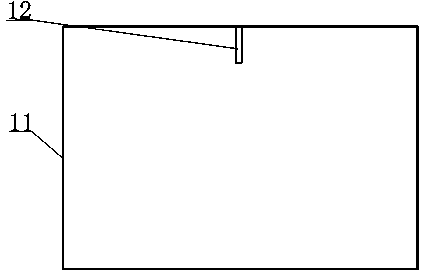

[0023] In order to further illustrate the present invention, introduce below in conjunction with accompanying drawing of description:

[0024] Refer to attached Figure 1-4 , a method for electrochemically measuring the thickness of a copper wire coating, specifically:

[0025] 1) Preheat the coating thickness tester for 10 minutes, set the instrument parameters according to the test requirements, and pour a special amount of chemical reagents into the plastic reaction cup;

[0026] 2) Cut the copper wire to be tested not less than 20MM (the end surface of the cut surface is required to be vertical and flat), and pass one end of the cut surface of the copper wire through the inner side of the length positioning rubber cap, and the copper wire The wire is inserted into the hole of the fixed-length die, and the rubber cap is moved and positioned so that the length of the copper wire exposed to the rubber cap is exactly the required reaction length;

[0027] 3) Clamp the copper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com