A continuously variable transmission for electric vehicles

A continuously variable transmission, electric vehicle technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of poor power flexibility, only a few gears, etc., to achieve reliable connection, improve flexibility, Simple connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

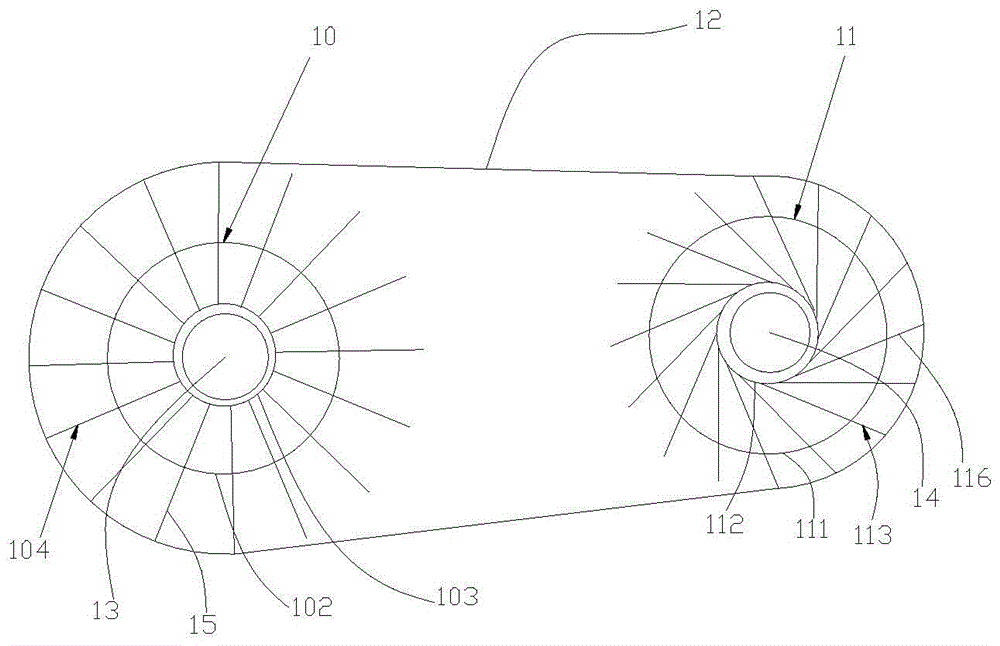

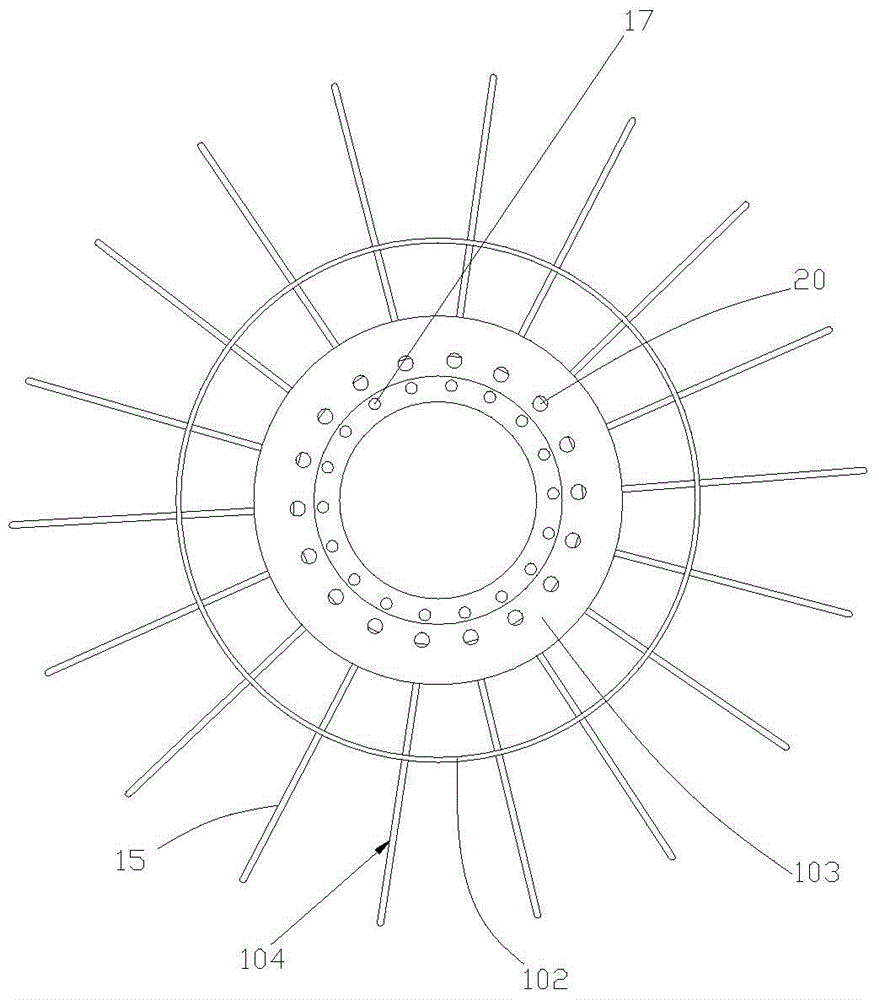

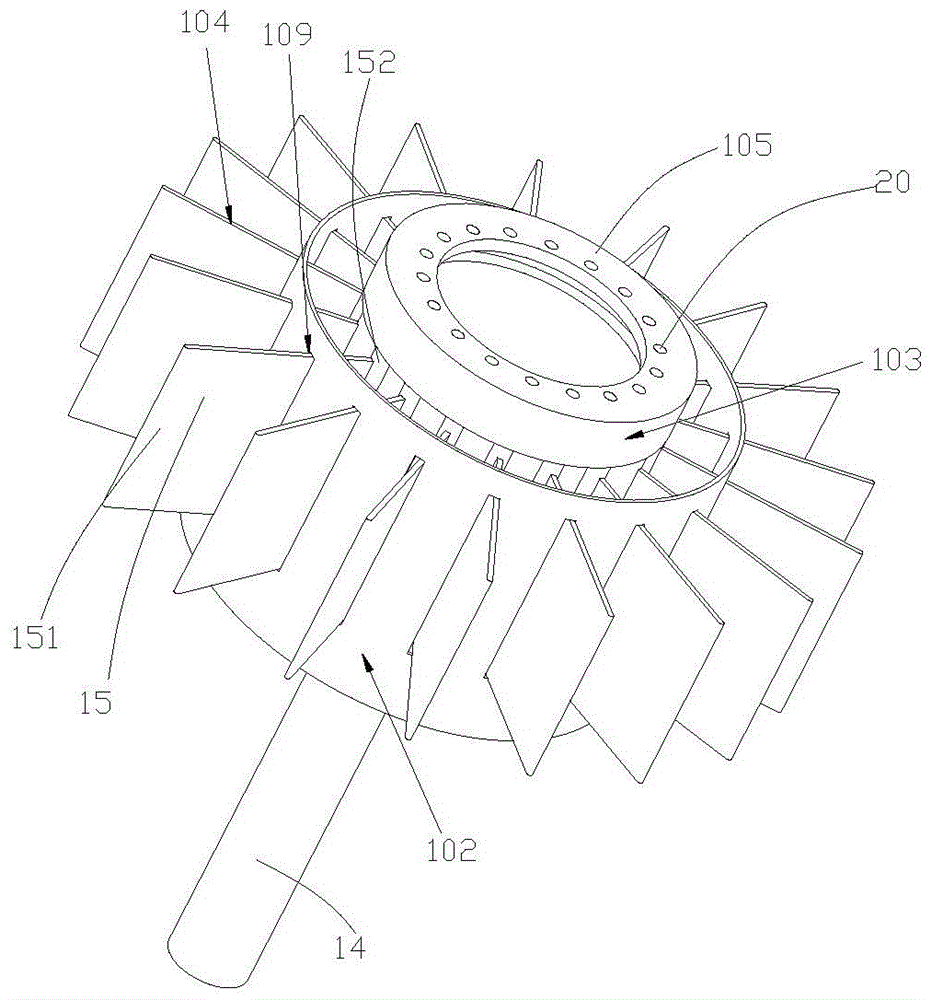

[0027] refer to figure 1 , image 3 with Figure 9 , a continuously variable transmission for an electric vehicle, comprising a driving wheel 10, a driven wheel 11, a track 12 for connecting the driving wheel 10 and the driven wheel 11, a power input shaft 13, a power output shaft 14, and a power input shaft 13 for driving A rotating drive motor (not shown). Such as figure 2 , image 3 with Figure 4 As shown, the driving wheel 10 includes a first motor (not shown in the figure), a first support frame 102 , a first rotating frame 103 , and a first support frame 104 . Such as Figure 7 As shown, the first rotating frame 103 includes a barrel-shaped first upper top cover 105 , a barrel-shaped first lower top cover 106 and a plurality of first installation rods 107 . The plurality of first installation rods 107 connect the first upper top cover 105 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com