Cutterhead device for large-diameter full-section impact crushing of hard rock

An impact crushing, full-section technology, used in mining equipment, earth-moving drilling, tunnels, etc., can solve the problems of large power load, fragile cutting tools, slow progress, etc., to achieve high efficiency, reduce power load, and continuous motion trajectory. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

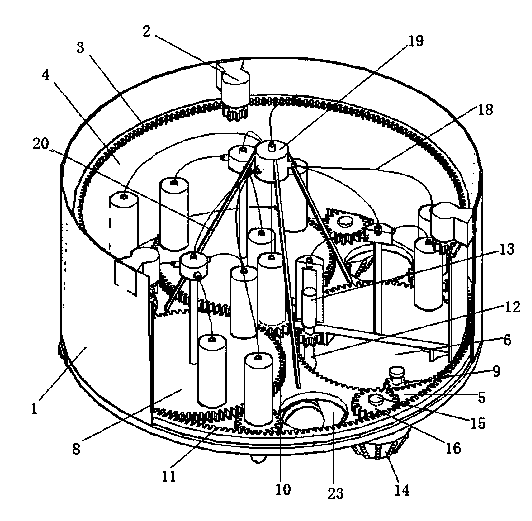

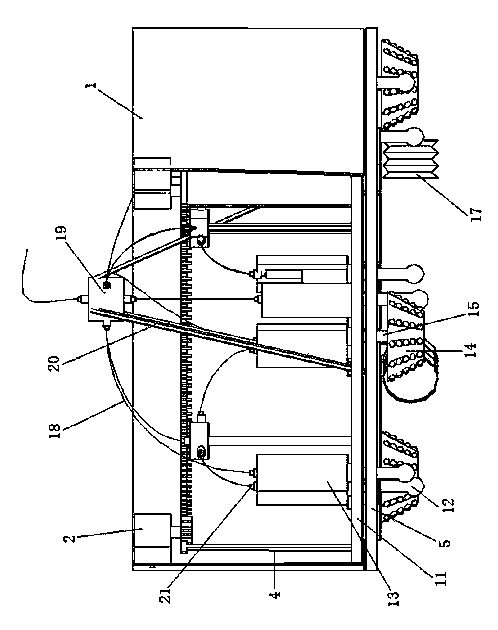

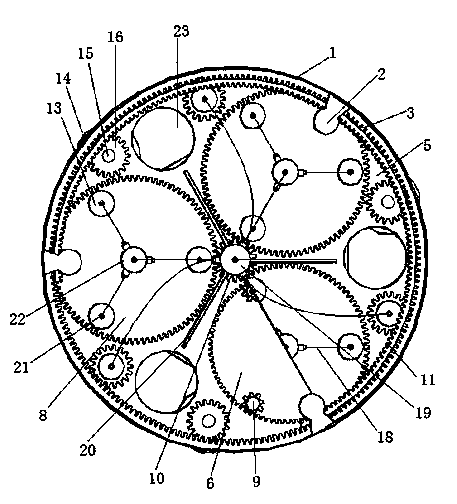

[0023] Embodiment one: in figure 1 , figure 2 , image 3 and Figure 4 Among them, the large-diameter and full-section cutter head device for impacting and crushing hard rock includes two parts: a mechanical transmission and a drilling tool. The mechanical transmission part includes an outer shell ring 1, and three main drives are installed on the inner side of the outer shell ring 1 at 120 degrees to each other. Motor 2, the main drive motor 2 meshes with the transmission ring gear 3 through the gear on the output shaft, the transmission ring gear 3 is fixed behind the transmission cylinder 4, and the transmission cylinder 4 is installed in the outer shell ring 1, which Shaft, drive cylinder 4 fronts are fixed with revolution big cutterhead 5. There are three gear holes 6 that form 120 degrees each other on the large revolving cutterhead 5, and a center hole 7 is also arranged in the middle of the large revolving cutterhead 5. Planetary gear discs 8 are installed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com