Device and method for measuring slippage among gas phase, liquid phase and solid phase in shaft annulus

A wellbore annulus and measurement method technology, applied in the field of oil and gas wells, can solve the problems of lack of measurement equipment and methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The above solution will be further described below in conjunction with specific embodiments. It should be understood that these examples are used to illustrate the present invention and not to limit the scope of the present invention. The implementation conditions adopted in the examples can be further adjusted according to the conditions of specific manufacturers, and the implementation conditions not indicated are usually the conditions in routine tests.

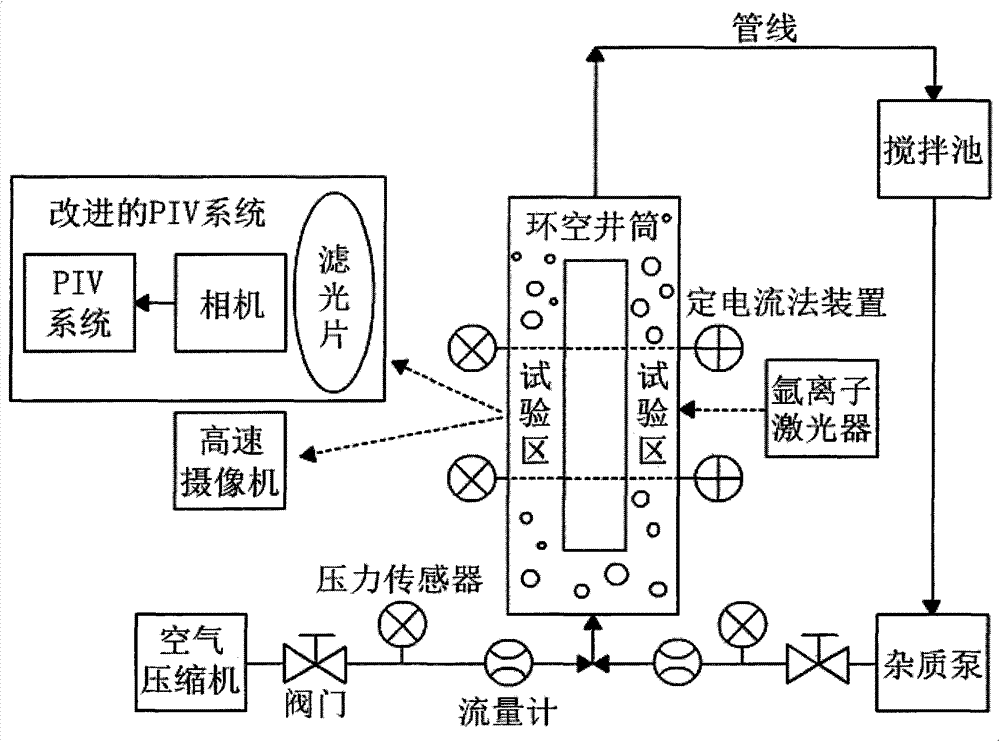

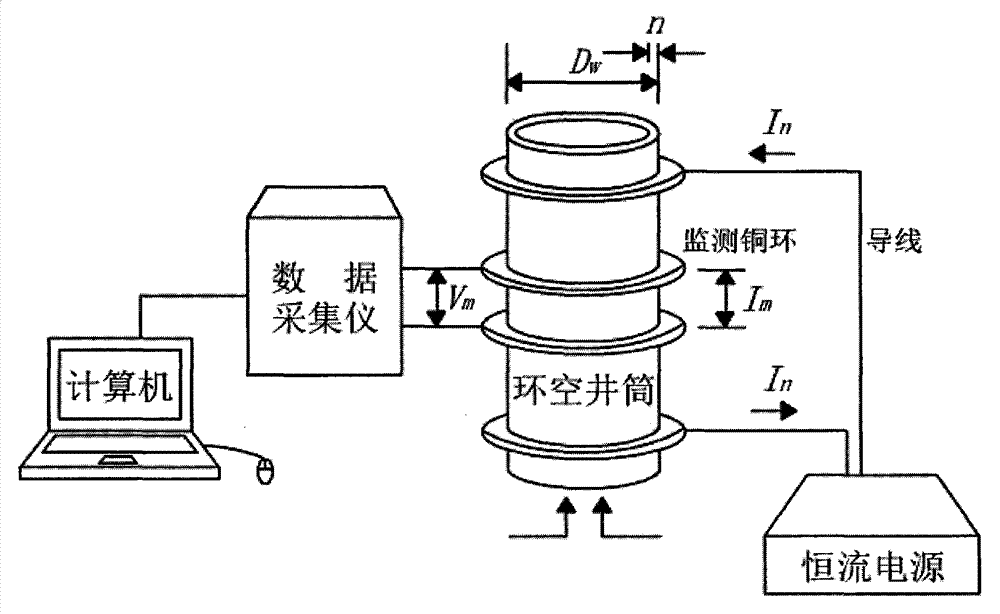

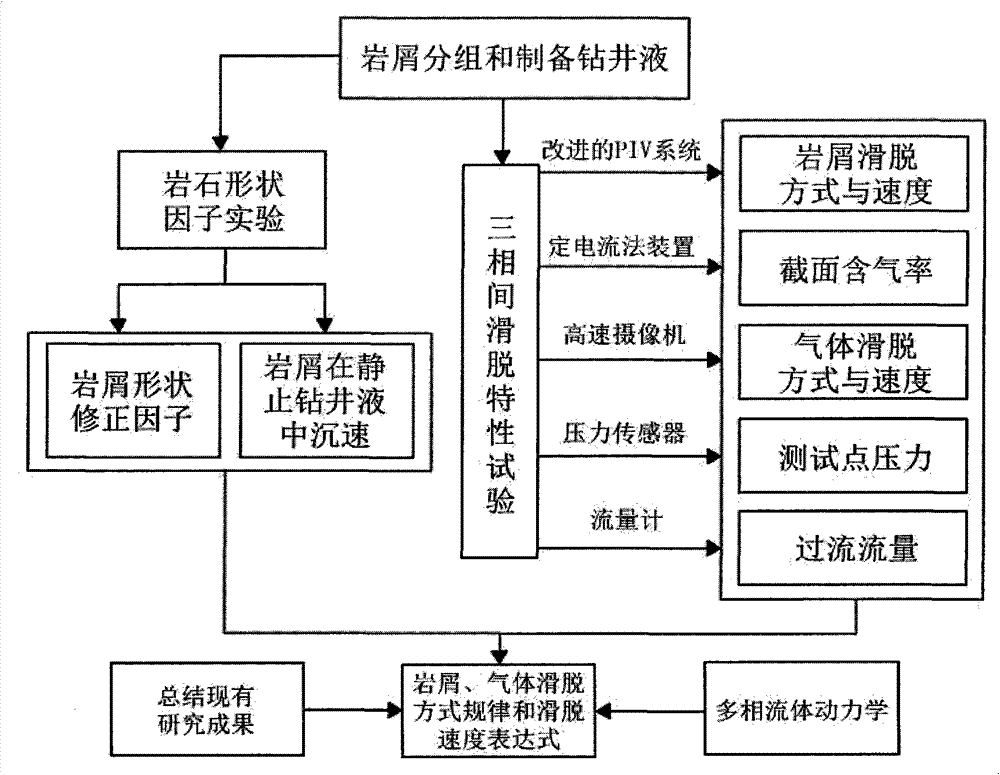

[0045] Please refer to Figure 1 to Figure 2 , figure 1 Schematic diagram of the layout of the gas-liquid-solid three-phase slip measurement equipment in the wellbore annulus provided by the embodiment of the present invention; figure 2 It is a schematic diagram of the structure of the device for measuring the cross-sectional gas fraction by the constant current method provided by the embodiment of the present invention.

[0046] In a specific embodiment, a device for measuring slippage between gas-liquid-solid ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com