A column-beam type grouting device and its hole-sealing grouting process

A grouting device, column beam technology, applied in sealing/isolation, wellbore/well parts, earthwork drilling and production, etc., can solve the damage of the original hole casing, the sealing hole grouting cannot be carried out, and the water supply hole grouting device Unable to fix problems, to achieve the effect of saving drainage costs, saving mine water treatment costs, and easy control of grouting pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

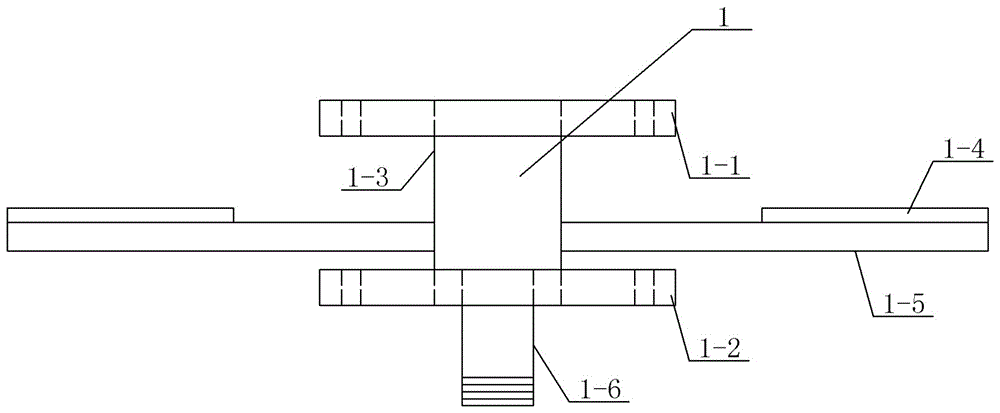

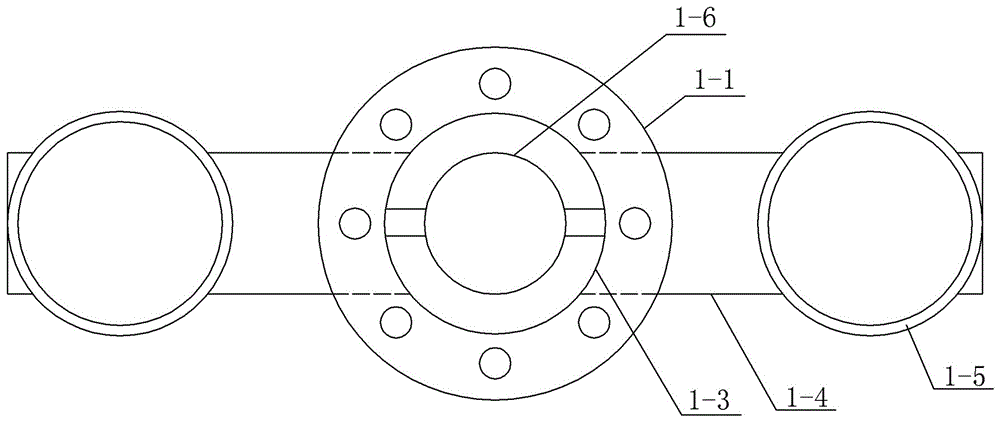

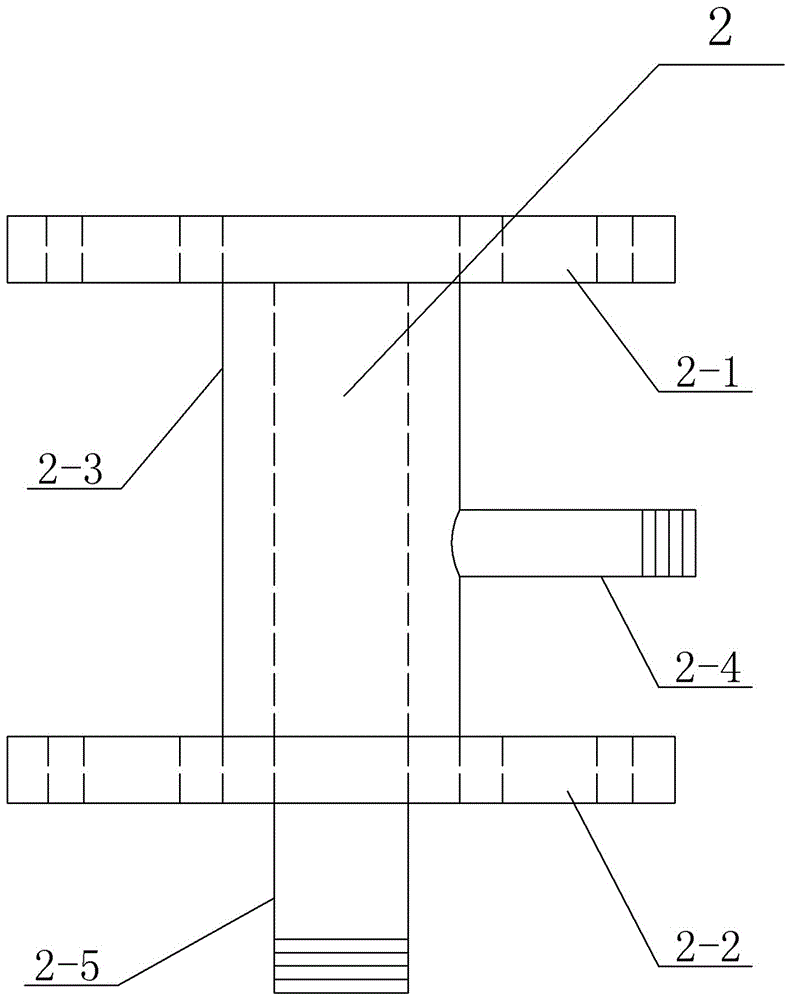

[0024] In the description of the drawings, the number 1 is the fixing device, 1-1 the upper end flange, 1-2 the lower end flange, 1-3 the middle short connection pipe, 1-4 I-shaped steel column beam, 1-5 column socket, 1-6 Casing joint, 2 grouting pipe connection device, 2-1 upper end flange, 2-2 lower end flange, 2-3 intermediate short connection pipe, 2-4 grouting pipe joint, 2-5 short casing, 3 The long casing that goes into the original hole, 4 pressure columns, 5 high-pressure gate valves, 6 long casings, and 7 grouting bulkheads.

[0025] A column-beam type grouting device and its sealing grouting process of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

[0026] The inner casing of a water supply hole is Φ89mm, a total of 46m, and the outer casing is Φ108mm, a total of 25m. Due to long-term water corrosion at the connection between the flange plate and the casing of the water supply hole, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com