Construction method for brick forms of foundation platforms and grade beams

A technology for foundation caps and construction methods, which is applied in infrastructure engineering, artificial islands, water conservancy projects, etc., can solve the problems of long construction period of brick membrane masonry, long construction period of brick membrane, and large amount of labor input, etc. Achieve good economic and social benefits, high rigidity, and improve efficacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

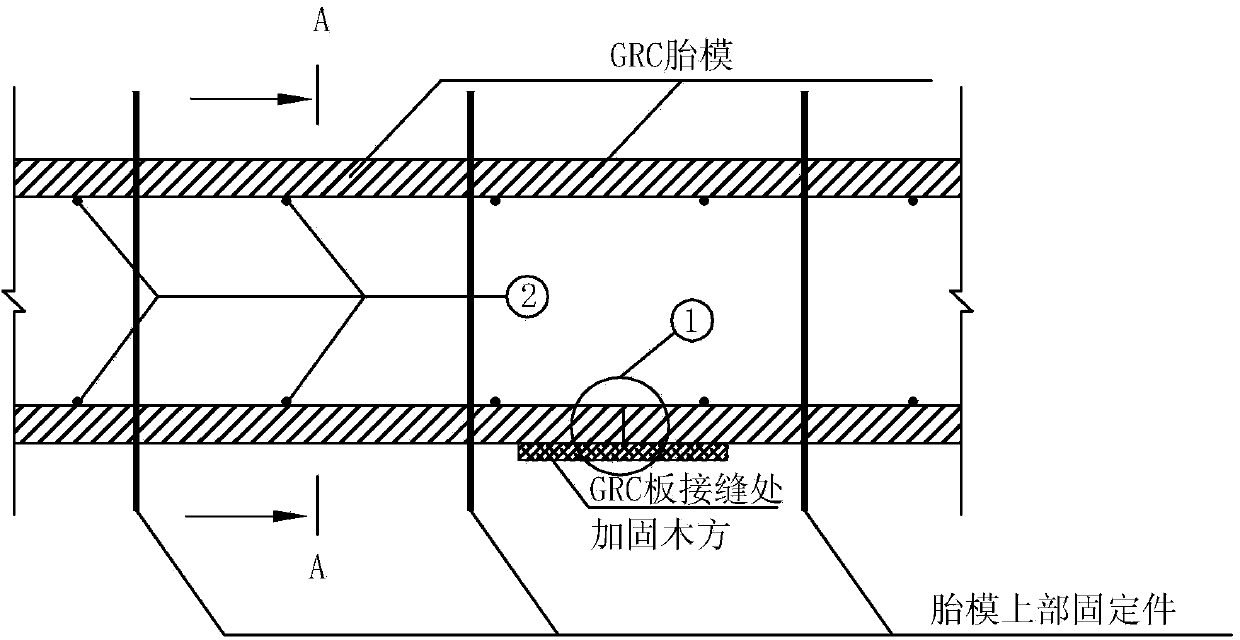

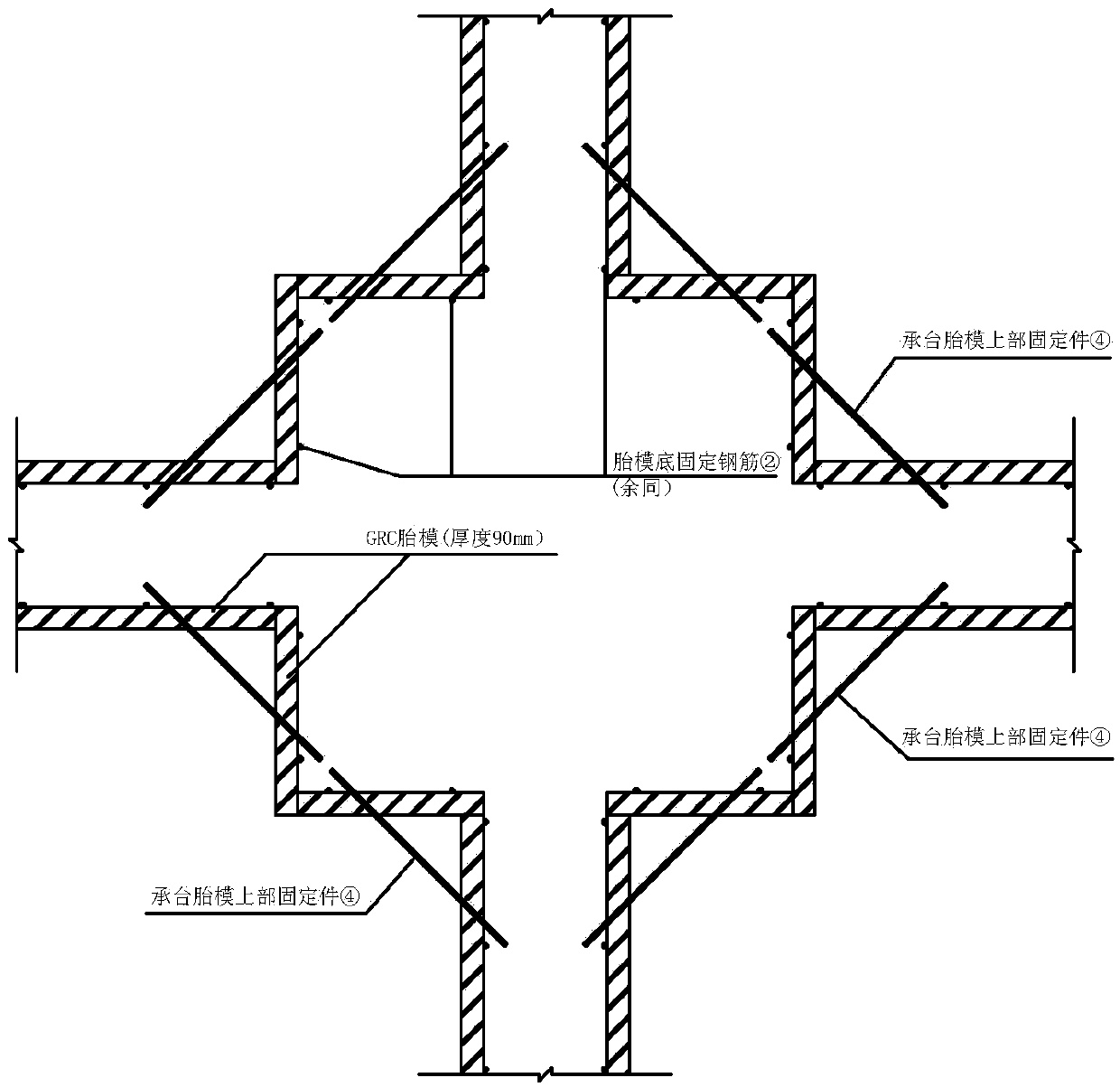

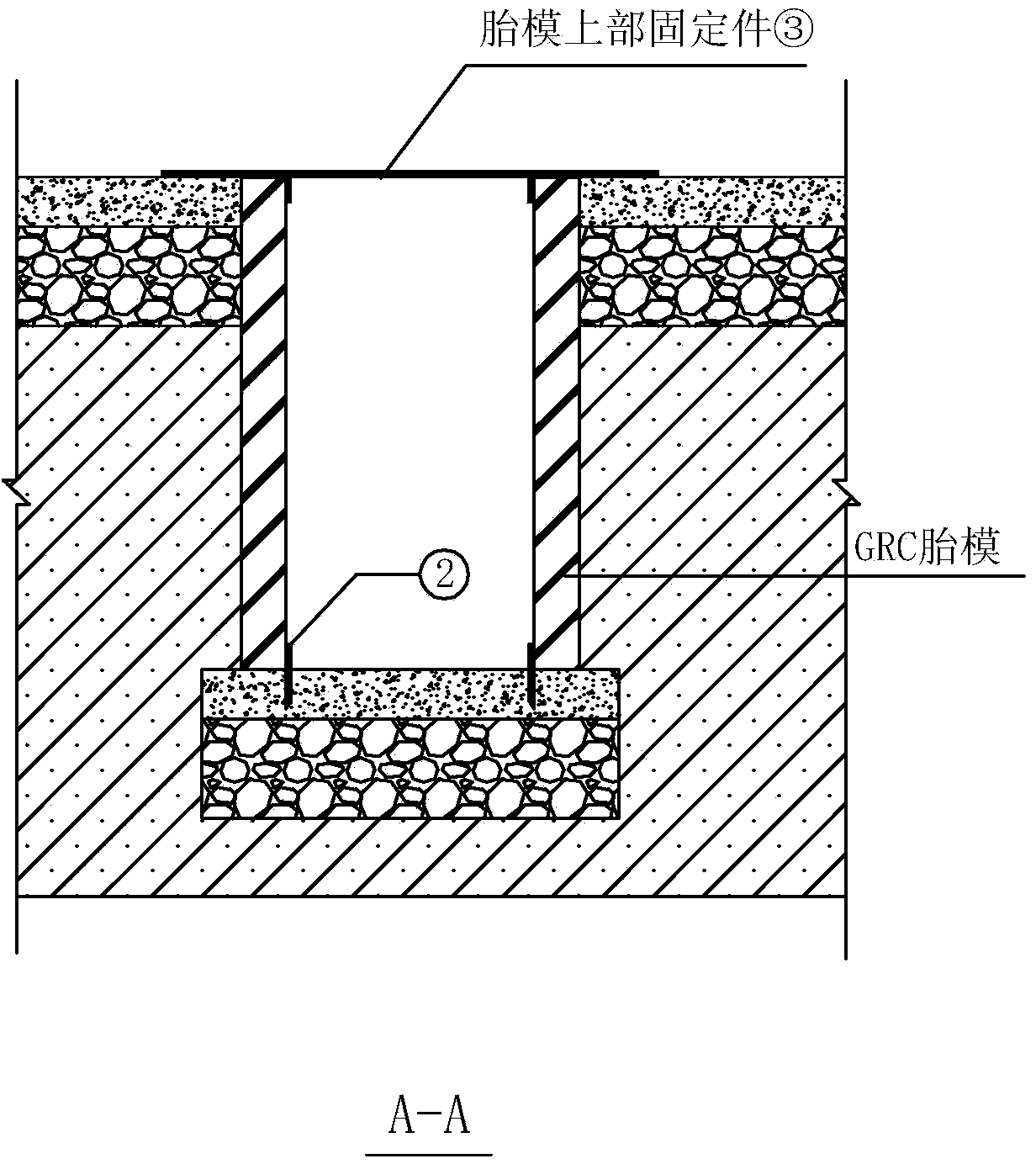

[0024] A method for constructing a membrane of a foundation cap and a ground beam, comprising the following steps: formulating a GRC membrane board according to engineering drawings; excavating and repairing foundation grooves on site; Installation of GRC tire formwork; backfilling of the outer side of the tire mold; reinforcement of the tire mold; review of the axis and the size of the ground beam and cap; pouring concrete.

[0025] The present invention further provides that the bottom plate of the foundation pit is leveled, and the foundation groove is positioned and laid out.

[0026] The present invention is further provided that manual excavation of earthwork is adopted according to the excavation sideline of foundation trench earthwork, and the excavated earthwork is transported out of the foundation pit by means of materials. , After the foundation trench is excavated to the elevation, the sides of the foundation trench should be trimmed and smoothed, and the loose ear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com