Blocking plate for plugging gap in bottom of guardrail hanging plate and using method thereof

A guardrail and hanging board technology, which is applied in construction, bridge construction, bridges, etc., can solve the problems of time-consuming and labor-consuming, poor sealing effect, and the gap between the hanging board and the flange board.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

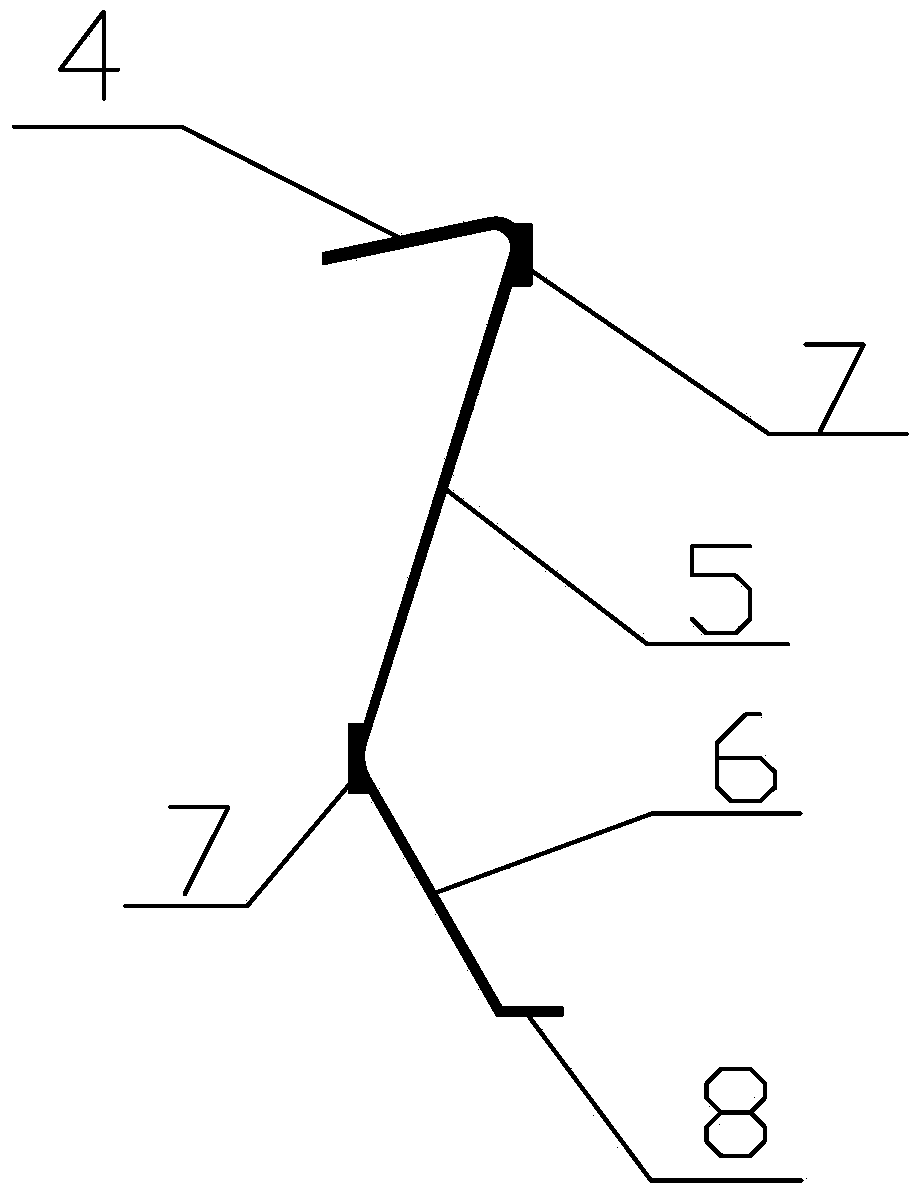

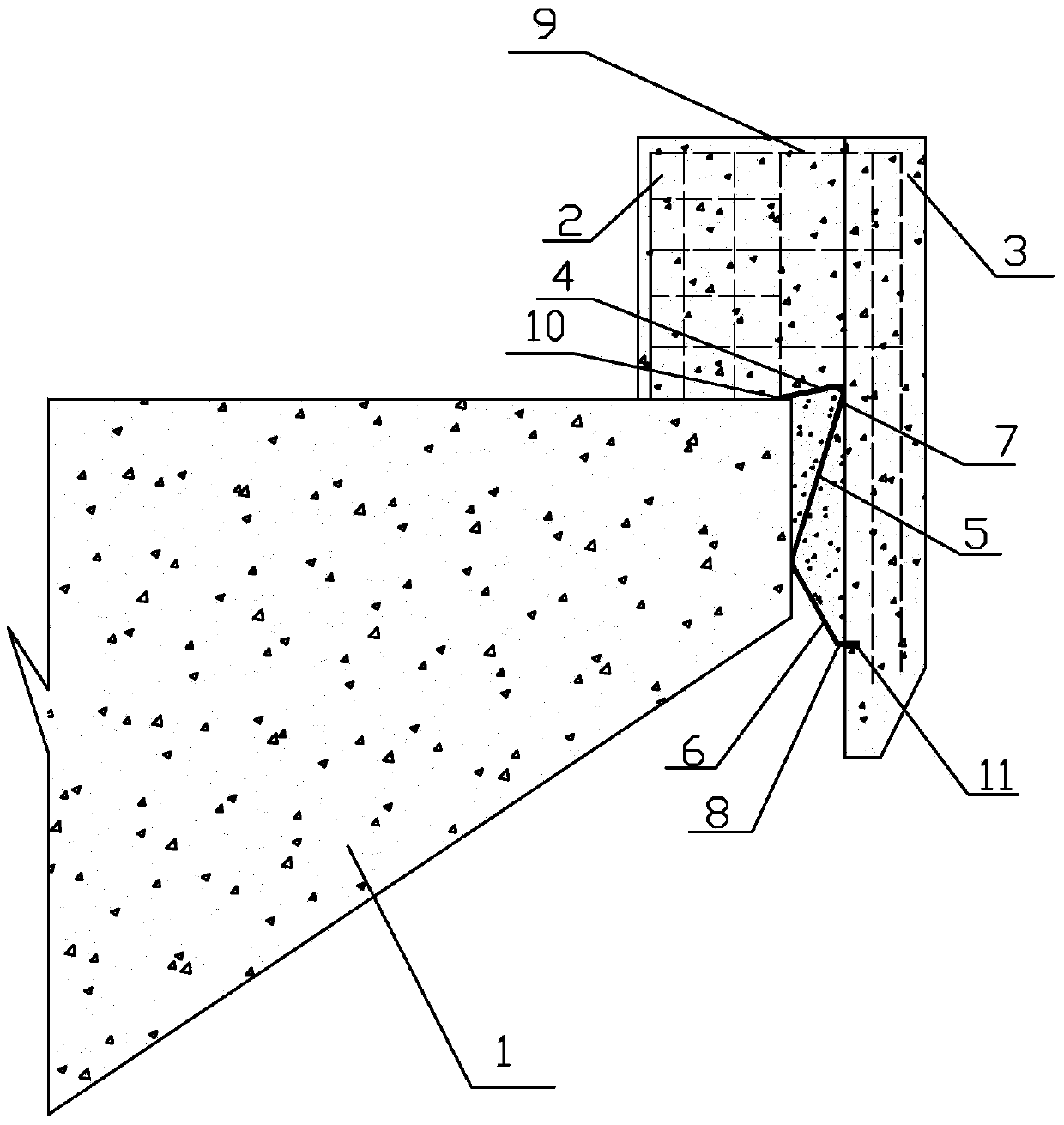

[0020] Combine figure 1 versus figure 2 In the present invention, the baffle body can be made of PPR or other plastic materials with good hardness, toughness and weather resistance according to the minimum section size of the flange plate 1 and the gap between the guardrail hanging plate 3 and the flange plate 1. Pre-made. The above-mentioned baffle body is composed of three sections of baffle which are sequentially connected as a whole. The three sections of baffle are the upper baffle 4, the middle baffle 5 and the lower baffle 6, respectively. The cross-sectional structure of the baffle body is under normal conditions. It is similar to the "Zigzag" font, and may be deformed differently from the "Zig" font during use. Both the upper baffle and the middle baffle are provided with evenly distributed through holes with a diameter of 5-10 mm, and the lower baffle is a plate body without through holes. The width of the above-mentioned baffle body is 20-50mm larger than the maxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com