Water-in-water colorful reflective insulating stone-like coating and preparation method thereof

A stone-like paint and water-in-water technology, which is applied in the direction of reflection/signal paint, multi-color effect paint, coating, etc., can solve the problem that the transparent coating film does not have the ability of reflection and heat insulation, the coating cannot provide thermal insulation function, Does not have thermal insulation function and other problems, to achieve the effect of continuous thermal insulation, reduce building energy consumption, and meet individual needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

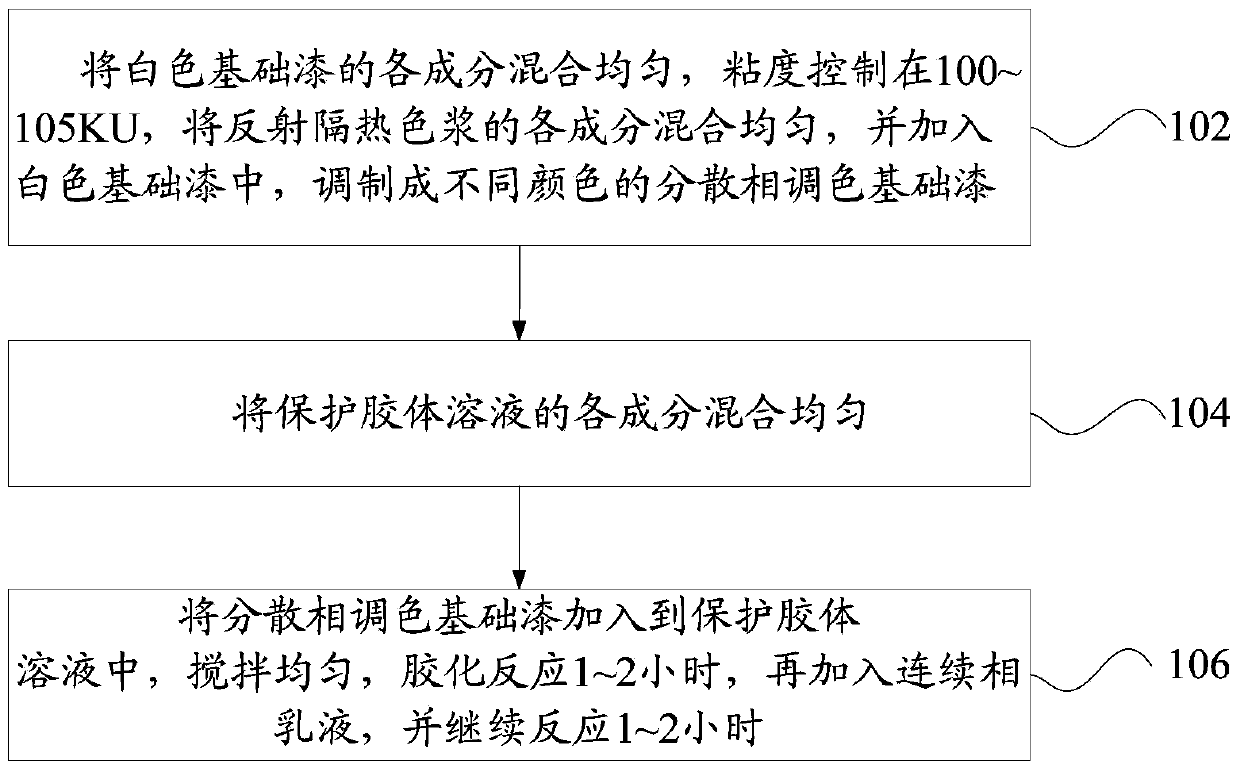

[0078] Such as figure 1 As shown, the embodiment of another aspect of the present invention provides a preparation method of water-in-water colorful reflective heat-insulating stone-like coating, which is used to prepare the water-in-water colorful reflective heat-insulated stone-like coating of any of the above embodiments, including:

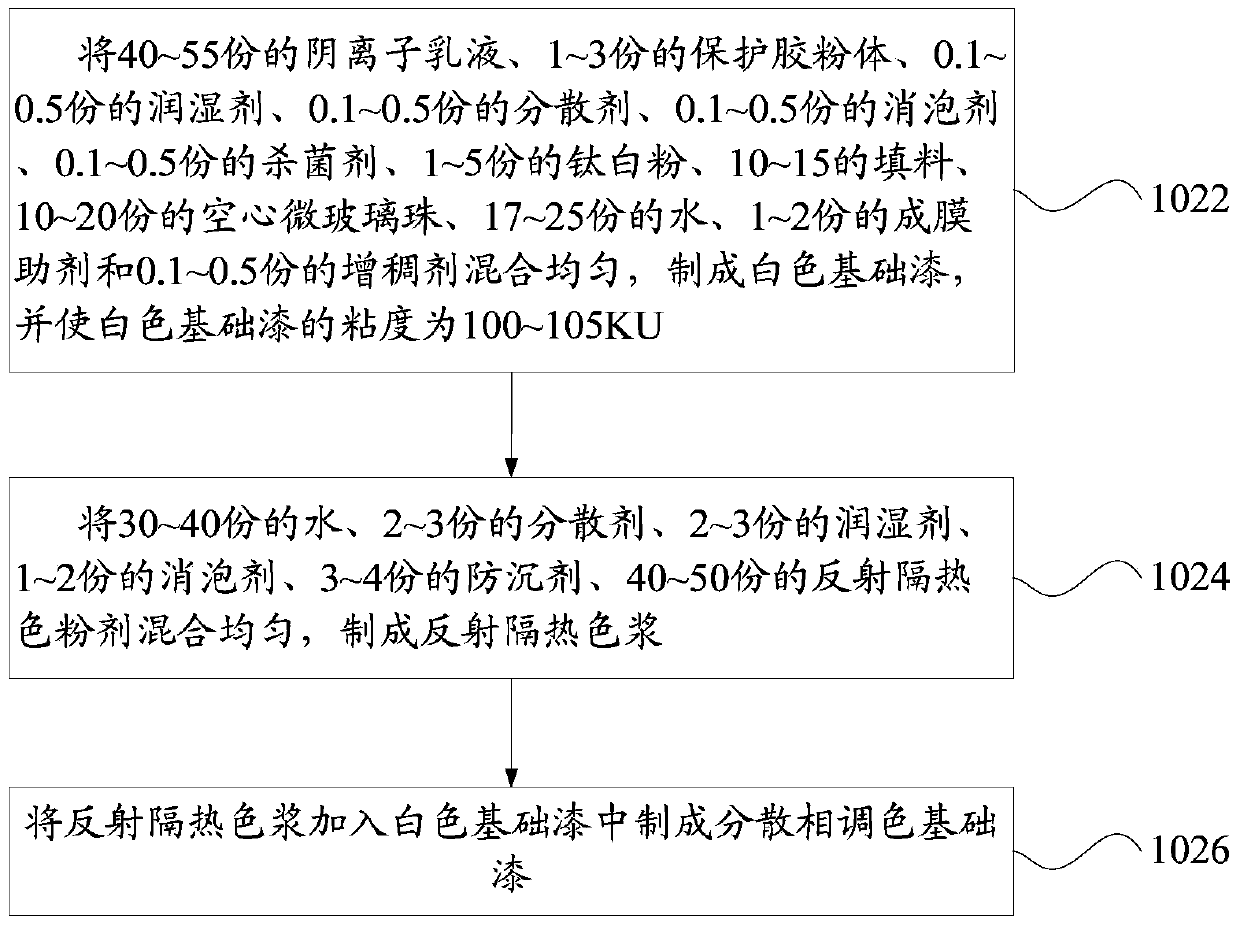

[0079] Step 102, mix the components of the white base paint evenly, and control the viscosity at 100-105KU, mix the components of the reflective heat-insulating color paste evenly, and add them to the white base paint to prepare different colors of dispersed-phase toned base paints ;

[0080] Step 104, mixing the components of the protective colloid solution evenly;

[0081] Step 106, adding the dispersed phase toning base paint into the protective colloid solution, stirring evenly, gelling for 1-2 hours, then adding the continuous phase emulsion, and continuing the reaction for 1-2 hours.

[0082] Further, as figure 2 As shown, step 102 i...

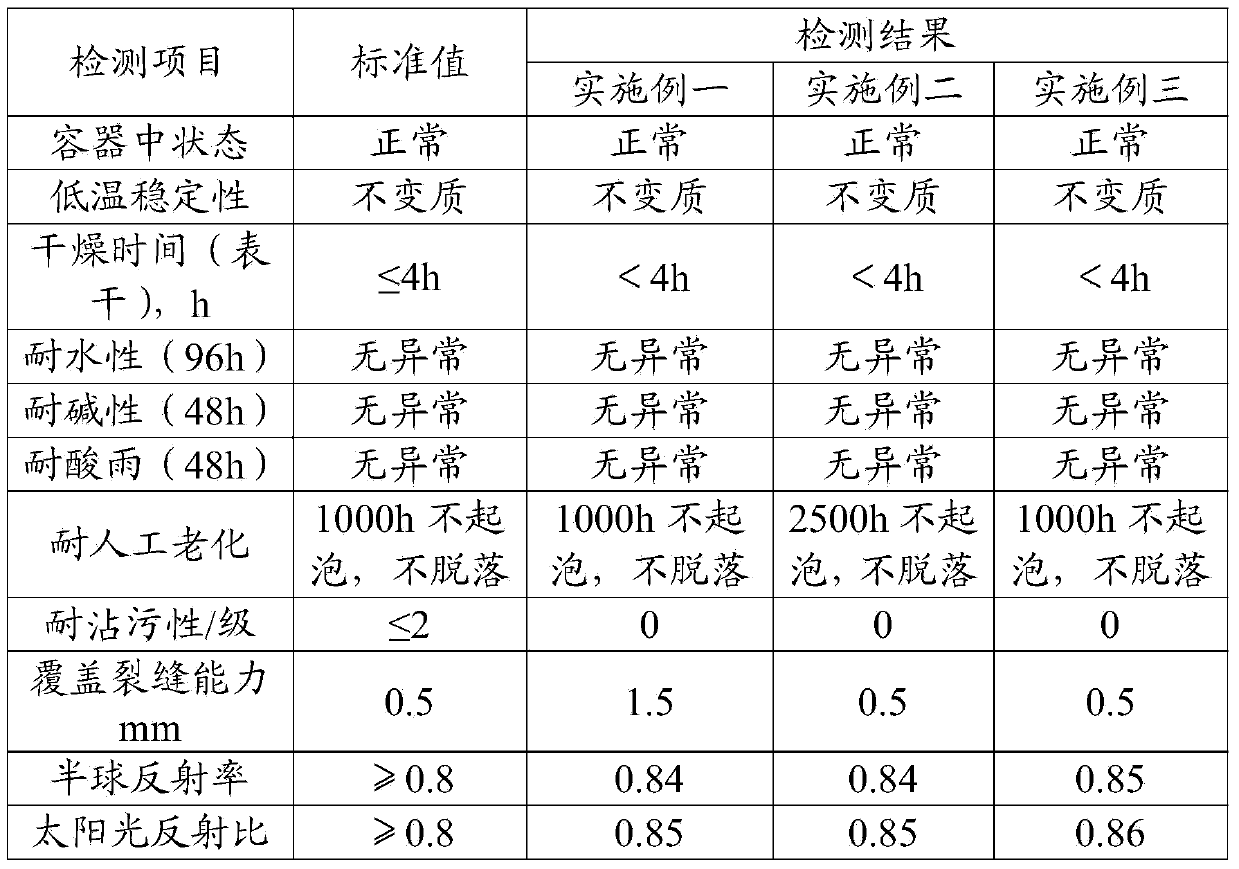

Embodiment 1

[0104] The water-in-water colorful reflective heat-insulating stone imitation paint of this embodiment includes a dispersed-phase toning base paint, a colloid and a continuous-phase emulsion, wherein the weight ratio between them is 30:40:30.

[0105] The components contained in the white base paint and the weight ratio of each component are: 55 parts of elastic pure acrylic emulsion, 3 parts of protective rubber powder, 0.2 part of wetting agent, 0.2 part of dispersant, 0.3 part of defoamer, and 0.1 part of bactericide , 2 parts of titanium dioxide, 10 parts of filler, 10 parts of hollow glass beads, 2 parts of film-forming aid, 0.2 part of thickener, and 17 parts of water.

[0106] The components contained in the reflective heat-insulating color paste and the weight ratio of each component are: 40 parts of water, 3 parts of dispersant, 3 parts of wetting agent, 1 part of defoamer, 4 parts of anti-settling agent, and 50 parts of reflective heat-insulating toner share.

[0107]...

Embodiment 2

[0124] The basic process of this embodiment is the same as that of Embodiment 1, the difference is that the anionic emulsion in the dispersed-phase toning base paint in the white base paint in the water-in-water colorful reflective heat-insulating stone-like paint uses modified silicon acrylic emulsion, and the continuous phase emulsion uses Fluorocarbon emulsion is added to further improve the weather resistance of the coating.

[0125] The water-in-water colorful reflective heat-insulating stone imitation paint of this embodiment includes a dispersed-phase toning base paint, a protective colloid solution and a continuous-phase emulsion, wherein the weight ratio between them is 30:35:35.

[0126] The components contained in the white base paint and the weight ratio of each component are: 50 parts of modified silicone acrylic emulsion, 3 parts of protective rubber powder, 0.2 parts of wetting agent, 0.2 parts of dispersant, 0.3 parts of defoaming agent, and 0.1 part of fungicid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com