Environment-friendly formaldehyde preparation process

A formaldehyde preparation and environmental protection technology, applied in the field of chemical production, can solve the problems of low alcohol content, large one-time investment and high unit consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

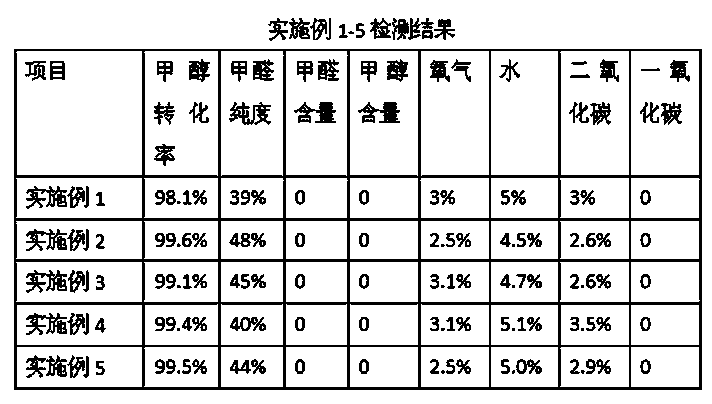

Embodiment 1

[0023] Methanol is transported into the methanol vaporizer by the pump for vaporization, and at the same time, the air is sent into the air by the fan for mixing. After mixing, the methanol gas accounts for 6% of the volume of the air. After mixing, the mixed gas is transported to the preheater. The preheating temperature is 100°C. After fully preheating, enter the reactor, the temperature in the reactor is 200 ° C, the catalyst is iron molybdenum catalyst, the catalyst dosage is 1.5% of the weight of methanol, and the reaction time is 2 minutes. During the reaction, the heat released by the reaction is removed by the vaporization of the heat transfer oil Therefore, the temperature in the reactor is kept at 270°C. After the formaldehyde gas from the reactor is preheated by the raw material of the methanol vaporizer, the temperature drops by 100°C and enters the absorption tower, where it exchanges heat with the process water flowing in the opposite direction and is diluted. Whe...

Embodiment 2

[0026] Methanol is transported into the methanol vaporizer by the pump for vaporization, and at the same time, the air is sent into the air by the fan for mixing. After mixing, the methanol gas accounts for 6% of the volume of the air. After mixing, the mixed gas is transported to the preheater. The preheating temperature is 100°C. After fully preheating, enter the reactor, the temperature in the reactor is 200°C, the catalyst is an iron-molybdenum catalyst, the catalyst dosage is 2.5% of the weight of methanol, and the reaction time is 3 minutes. During the reaction, the heat released by the reaction is removed by the vaporization of the heat transfer oil. In order to keep the temperature in the reactor at 280°C, the formaldehyde gas from the reactor is preheated by the raw material of the methanol vaporizer, the temperature drops by 110°C, and enters the absorption tower, where it exchanges heat with the process water flowing in the opposite direction and dilutes it. When the...

Embodiment 3

[0029] Methanol is transported into the methanol vaporizer by the pump for vaporization, and at the same time, the fan is sent into the air for mixing. After mixing, the methanol gas accounts for 8% of the volume of the air. After mixing, the mixed gas is transported to the preheater. The preheating temperature is 100°C. After fully preheating, enter the reactor, the temperature in the reactor is 200°C, the catalyst is an iron-molybdenum catalyst, the catalyst dosage is 2.5% of the weight of methanol, and the reaction time is 3 minutes. During the reaction, the heat released by the reaction is removed by the vaporization of the heat transfer oil. In order to keep the temperature in the reactor at 280°C, the formaldehyde gas from the reactor is preheated by the raw material of the methanol vaporizer, the temperature drops by 110°C, and enters the absorption tower, where it exchanges heat with the process water flowing in the opposite direction and dilutes it. When the concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com