A device for glazing ceramic spark plug blanks

A technology for spark plugs and blanks, which is applied to the field of glazing devices for ceramic spark plug blanks, can solve the problems of uneven thickness of the glaze surface, high production cost, easy to hang glaze, etc., and achieve uniform thickness of the glaze layer, simple structure, and difficult to hang glaze. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

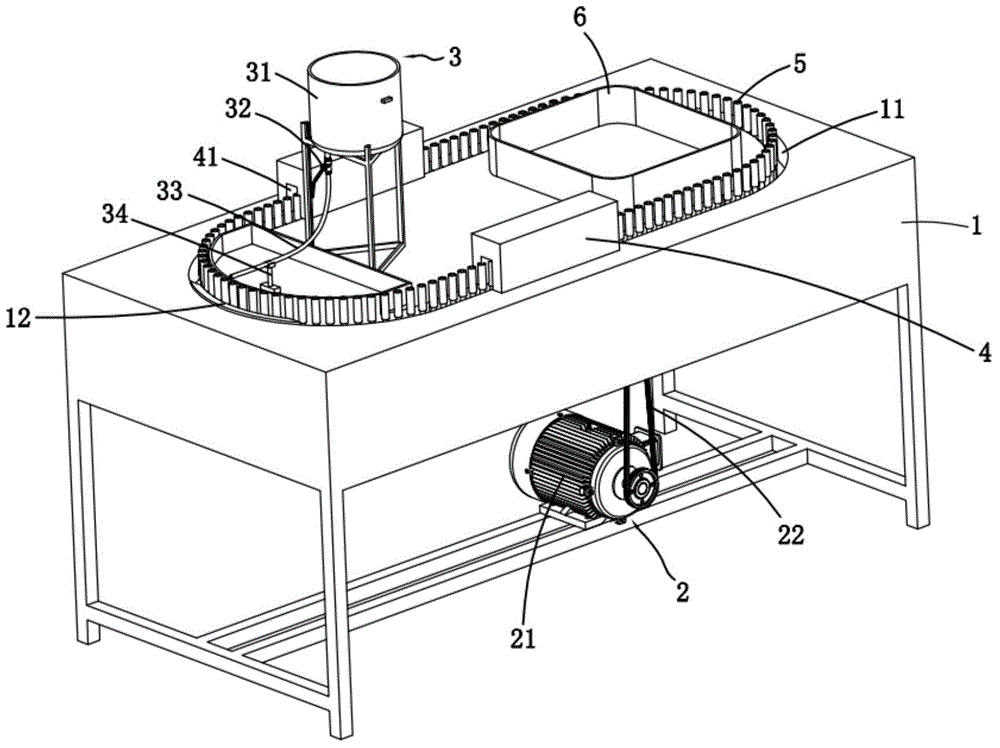

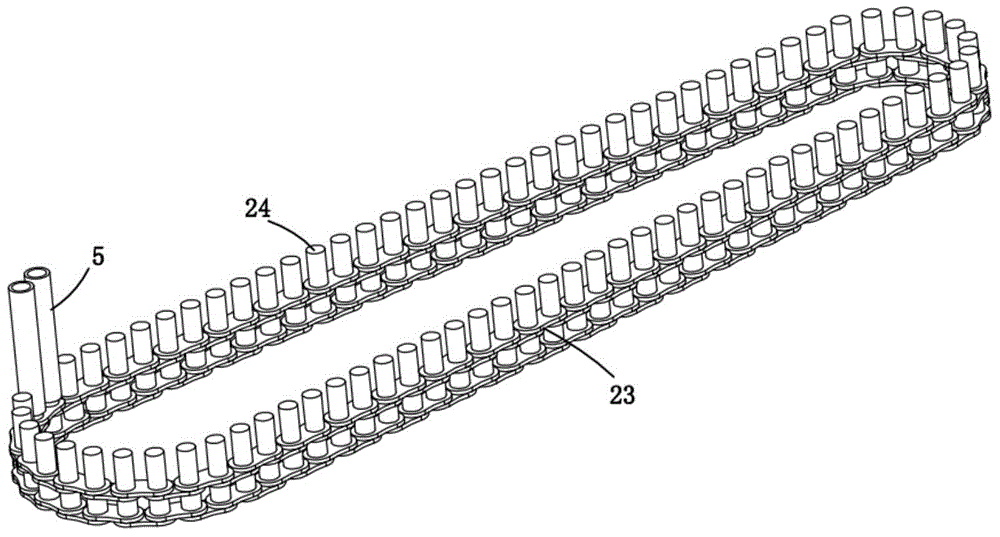

[0017] Such as figure 1 As shown, a ceramic spark plug blank glazing device includes a frame 1, a transmission mechanism 2, a glazing device 3 for spraying glaze on ceramic blanks, a heating device 4 and several cylinders for placing spark plug blanks shaped bracket 5, the transmission mechanism 2 includes a motor 21, a belt drive 22 and a chain 23, the working surface of the frame 1 is provided with a circular track 11 composed of a straight line part and an arc part, and the chain 23 is placed on the track 11 Inside, the chain 23 is equipped with rollers at the junction of the straight line part and the arc part of the track 11 (this is a known technology, which is shown in the figure), and is driven by the motor 21 through the belt drive 22 to circulate in the track 11 turn; as figure 2 As shown, the chain 23 is vertically provided with several rotating shafts 24, each rotating shaft 24 is sleeved with a cylindrical support 5 and placed in the track 11 in turn, the diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com