Driving swing arm rack

A swing arm and drive shaft technology is applied in the field of packaging units, which can solve the problems of inconvenient installation and disassembly, reduce production efficiency, increase production costs, etc., and achieve the effects of avoiding dimensional errors, reducing production costs, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

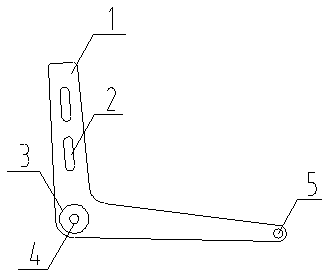

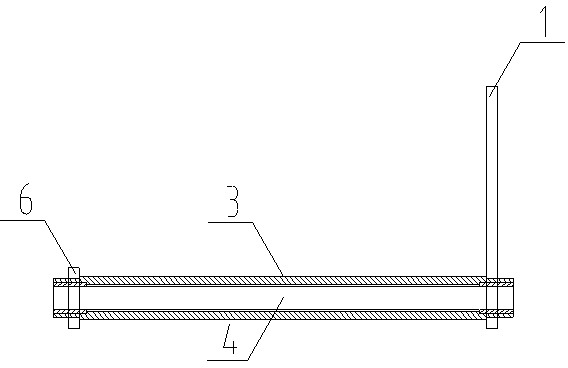

[0013] A driving swing arm frame, comprising a swing arm frame (1), characterized in that two waist-shaped holes (2) are opened on one side of the swing arm frame (1), and the rotating shaft of the swing arm frame (1) A drive shaft (3) is connected to the Z-axis direction, the drive shaft (3) has a fixed shaft hole (4), and the other end of the swing arm frame (1) has a connection hole (5). There is a positioning plate (6) on the shaft (3), and the swing arm frame is an L-shaped structure.

[0014] The driving source drives the waist-shaped hole (2) end of the swing arm frame (1), and the waist-shaped hole (2) can be fine-tuned. Since the two ends of the drive shaft (3) are fixed through the fixed shaft hole (4), the swing arm frame (1) The end with the connection hole (5) rotates around the drive shaft (3), the connection hole (5) is connected to the output part, and the drive shaft (3) is also rotating when the swing arm frame (1) moves, It can drive other components to rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com