A bevel gear push rod type aircraft head deflection drive device

A bevel gear and aircraft technology, which is applied in the directions of power plant, aircraft power transmission, aircraft parts, etc. on aircraft, can solve the problems of high cost of materials, complex amplifying mechanism, small lateral overload, etc., and achieves simple structure and working principle, satisfying Fast, good performance results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] This embodiment is a bevel gear push rod type aircraft head deflection driving device.

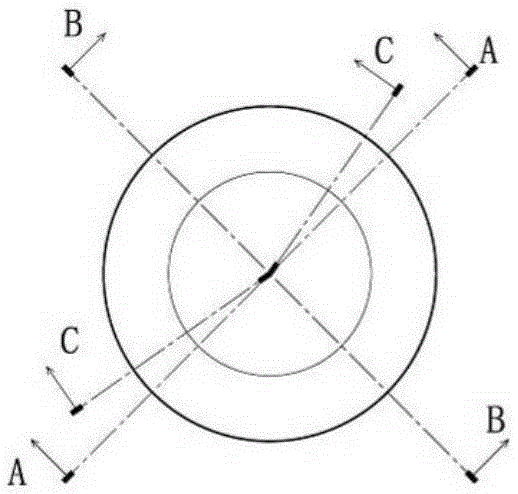

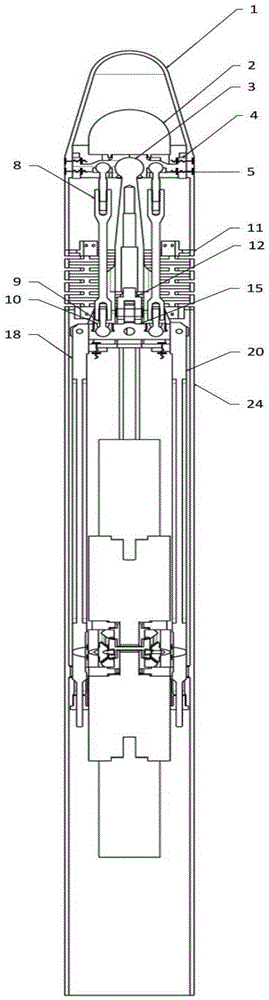

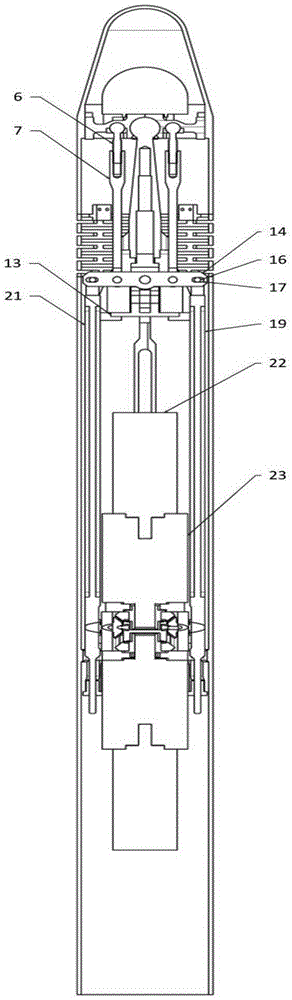

[0027] refer to Figure 1 to Figure 5, the bevel gear pushrod type aircraft head deflection drive device of this embodiment is composed of a support mechanism, a power mechanism, a bevel gear steering mechanism, a connecting rod transmission mechanism, a head and a rotating connecting arm mechanism, and an aircraft head-body connection mechanism; the support mechanism Including the base 24, the first sleeve base 13, the second sleeve base 12 and the spherical sleeve 3; the first sleeve base 13, the second sleeve base 12 and the spherical sleeve 3 are connected by screws , wherein the first sleeve base 13 is used as the center of rotation support of the first lever 15, the second sleeve base 12 is used as the center of rotation support of the second lever 14, and the ball head in the spherical sleeve 3 is used as the center of rotation of the connecting arm 4. The center of the ball...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com