A kind of nano cobalt hydroxide-graphene composite film, its preparation method and application

A graphene composite and nano-graphene technology, which is applied in the field of nanomaterials, can solve the problems of pollution, easy cracking of thin films, and high cost, and achieve the effects of wide application prospects, improved detection sensitivity, and improved detection limit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of described nanometer cobalt hydroxide-graphene composite membrane is characterized in that, comprises the following steps:

[0028] (1) Evenly disperse the graphene oxide in water to form a graphene oxide solution with a concentration of 2 mg / ml to 4 mg / ml; it is preferable to uniformly disperse the graphene oxide in ultrapure water by means of ultrasonic dispersion;

[0029] (2) The graphene oxide solution obtained in step (1) is coated on the sheet-shaped conductive substrate, and the coating amount is 0.5ml / cm 2 ~1ml / cm 2 , to obtain nano-graphene oxide film after drying;

[0030] (3) Set up a three-electrode system: the nano-graphene oxide film obtained in step (2) is used as a working electrode, the platinum electrode is used as an auxiliary electrode, and the saturated calomel electrode is used as a reference electrode, and each liter of electrolyte contains 40 mmol of cobalt sulfate to 60mmol and sodium sulfate 0.05mol to 0.15mol, using...

Embodiment 1

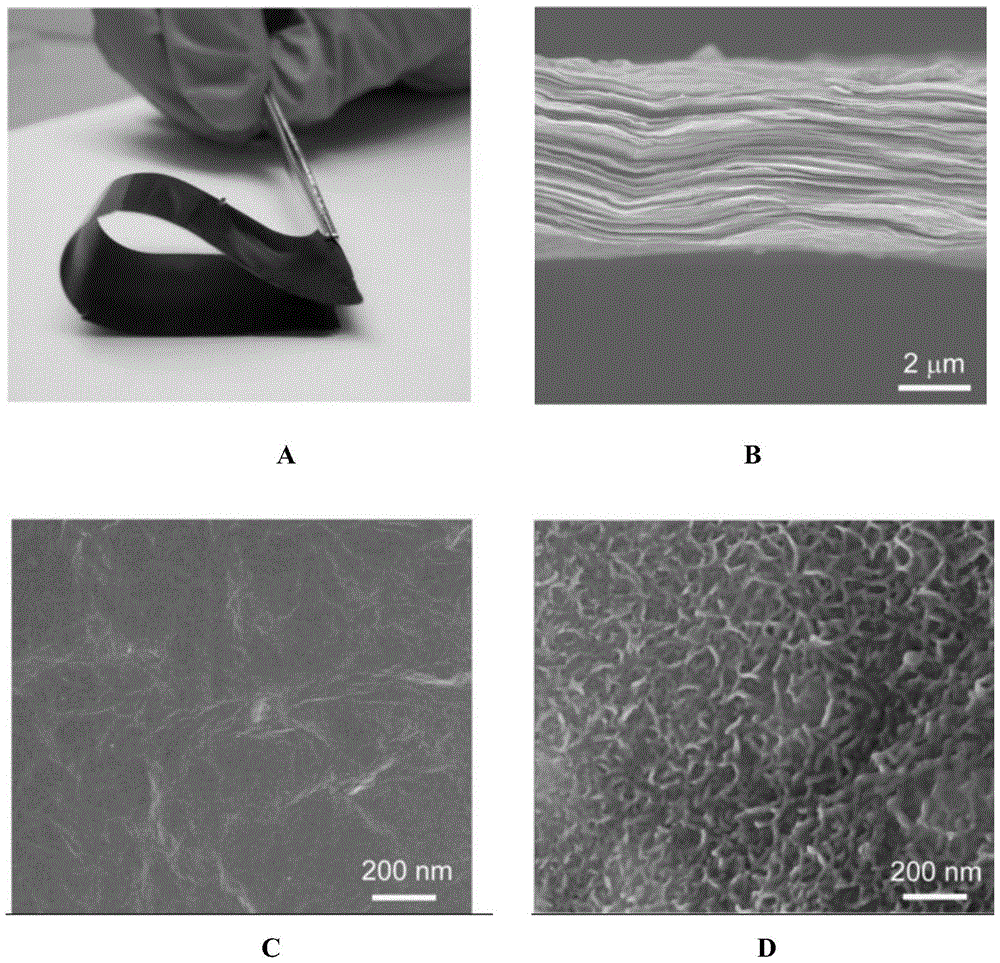

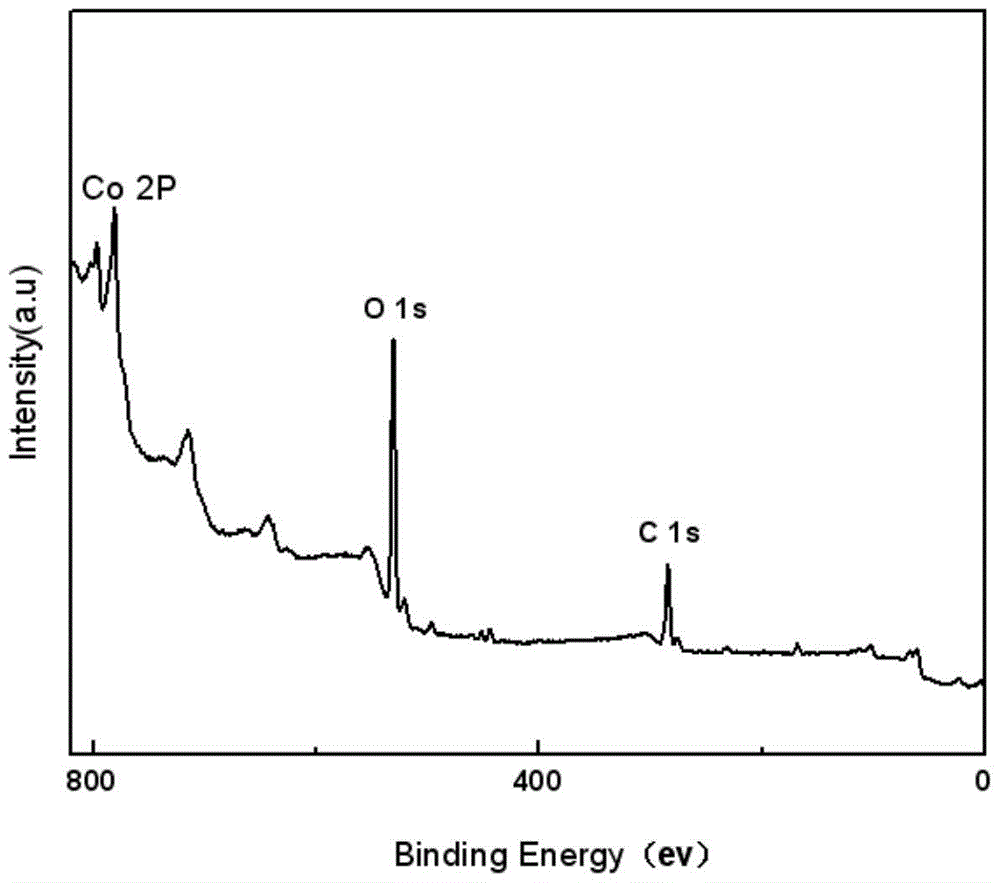

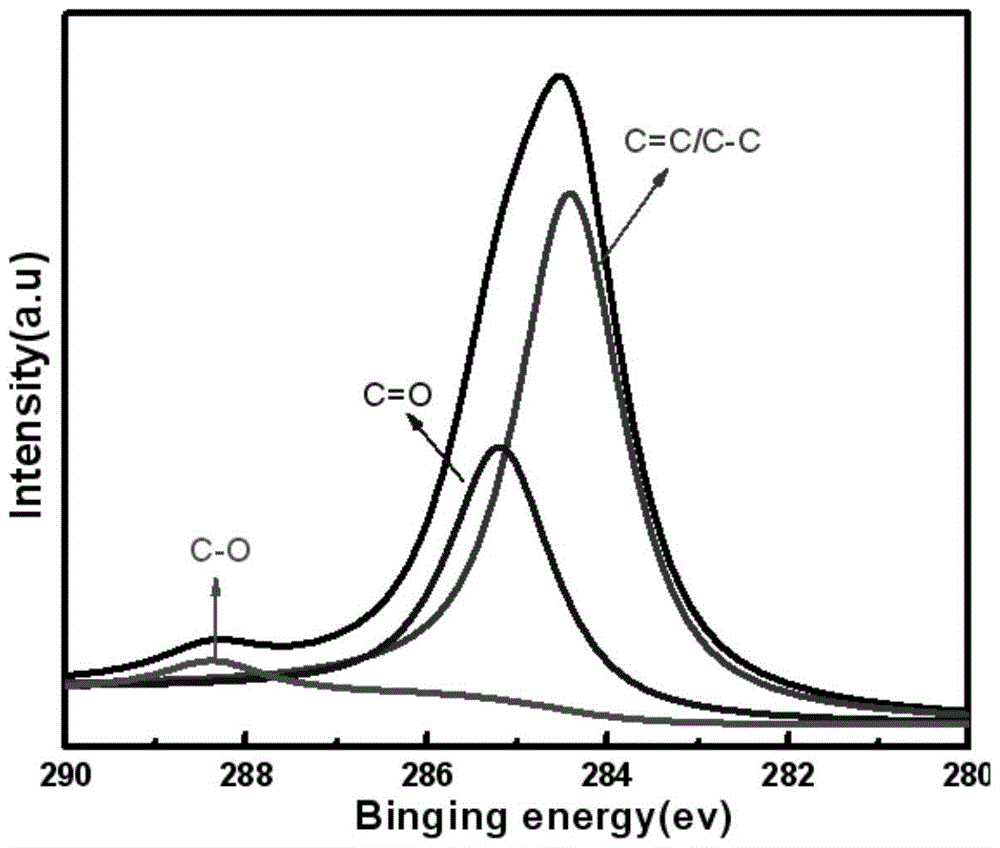

[0035] A nano-cobalt hydroxide-graphene composite film is characterized in that, comprising a nano-graphene bottom layer and a nano-cobalt hydroxide surface layer, the nano-graphene bottom layer thickness is 4000nm, and the nano-cobalt hydroxide surface layer thickness is 50nm, so The nano-cobalt hydroxide surface layer is evenly deposited on the nano-graphene bottom layer. The nano-graphene bottom layer has wrinkles and undulations in different degrees, and the nano-graphene sheets are in an interlocking state, so they have good macroscopic flexibility and rigidity; the nano-cobalt hydroxide layer is The nano-cobalt hydroxide layer is a uniform and fluffy nano-sheet structure.

[0036] The preparation method of described nanometer cobalt hydroxide-graphene composite film is characterized in that, comprises the following steps:

[0037](1) The aqueous solution of graphene oxide was prepared by the Hummers method, so that the graphene oxide was uniformly dispersed in water to ...

Embodiment 2

[0042] A nano-cobalt hydroxide-graphene composite film is characterized in that, comprising a nano-graphene bottom layer and a nano-cobalt hydroxide surface layer, the nano-graphene bottom layer thickness is 5000nm, and the nano-cobalt hydroxide surface layer thickness is 75nm, so The nano-cobalt hydroxide surface layer is uniformly deposited on the nano-graphene bottom layer. The nano-graphene bottom layer has wrinkles and undulations in different degrees, and the nano-graphene sheets are in an interlocking state, so they have good macroscopic flexibility and rigidity; the nano-cobalt hydroxide layer is The nano-cobalt hydroxide layer is a uniform and fluffy nano-sheet structure.

[0043] The preparation method of described nanometer cobalt hydroxide-graphene composite membrane is characterized in that, comprises the following steps:

[0044] (1) The aqueous solution of graphene oxide was prepared by the Hummers method, so that the graphene oxide was uniformly dispersed in w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com