Device and method for increasing absorption rate of iodine-containing tail gas

A technology of absorption rate and exhaust gas is applied in the field of devices for improving the absorption rate of iodine-containing exhaust gas, which can solve the problems of polluted environment, excessive iodine content, waste of resources, etc., and achieve the effects of good absorption effect, large contact area and remarkable absorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

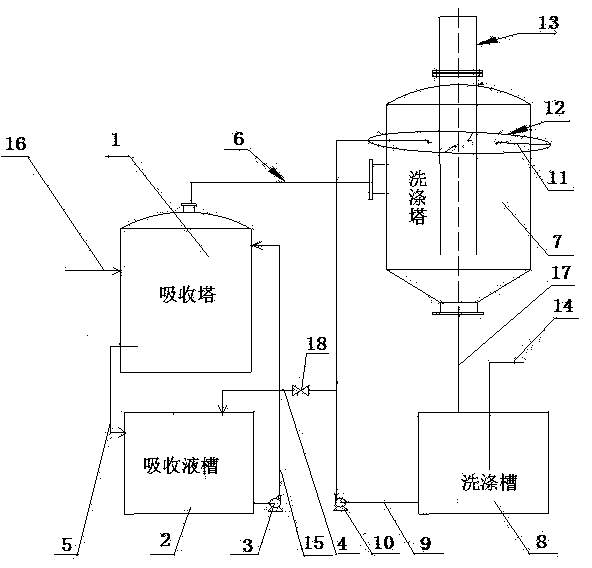

[0026] Iodine is extracted from the dilute phosphoric acid produced in the production process of iodine-containing phosphorus ore, iodine is separated, and the iodine is separated by means of filtration, and finally solid-liquid separation and filtration are achieved to obtain crude iodine and iodine-containing filtrate; The filtrate of L is added in the washing liquid tank 8 through the pipeline 14, and the SO of 40% of the mass percent of the filtrate is passed into 2 As a washing liquid; the mass percentage concentration is 20% sodium sulfite solution is packed in the absorption liquid tank 2 as the absorption liquid, and then sent to the absorption tower 1 by the pump 3, and simultaneously passes into the absorption tower through the pipeline 16 containing The extraction gas of iodine 40mg / L is returned in the absorption liquid tank 2 through the circulation line 5 after being absorbed by the absorption liquid in the absorption tower 1, and then is sent to the absorption t...

Embodiment 2

[0028] Iodine is extracted from dilute phosphoric acid produced in the production process of iodine-containing phosphorus ore, iodine is separated, and the iodine is separated by means of filtration, and finally solid-liquid separation and filtration are achieved to obtain crude iodine and iodine-containing filtrate; The filtrate of L is added in the washing liquid tank 8 by pipeline 14, and the SO of 45% of filtrate mass percentage is passed into 2 As a washing liquid; the mass percentage concentration is 20% sodium sulfite solution is packed in the absorption liquid tank 2 as the absorption liquid, and then sent to the absorption tower 1 by the pump 3, and simultaneously passes into the absorption tower through the pipeline 16 containing The extraction gas of iodine 35mg / L is returned to the absorption liquid tank 2 through the circulation pipeline 5 after being absorbed by the absorption liquid in the absorption tower 1, and then is sent to the absorption tower 1 by the pump...

Embodiment 3

[0030] Iodine is extracted from the dilute phosphoric acid produced in the production process of iodine-containing phosphorus ore, iodine is separated, and the iodine is separated by means of filtration, and finally solid-liquid separation and filtration are achieved to obtain crude iodine and iodine-containing filtrate; The filtrate of L is added in the washing liquid tank 8 through the pipeline 14, and the SO of 35% of the mass percent of the filtrate is passed into 2 As a washing liquid; the mass percentage concentration is 20% sodium sulfite solution is packed in the absorption liquid tank 2 as the absorption liquid, and then sent to the absorption tower 1 by the pump 3, and simultaneously passes into the absorption tower through the pipeline 16 containing The extraction gas of iodine 20mg / L is returned in the absorption liquid tank 2 through the circulation line 5 after being absorbed by the absorption liquid in the absorption tower 1, and then is sent to the absorption t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com