An automatic bean peeling machine

A bean machine, automatic technology, applied in application, food processing, food science and other directions, can solve the problems of consuming long working time, unable to peel off the bean skin, and high processing cost, achieving effective reciprocating cycle movement, convenient consumption and processing production, The effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

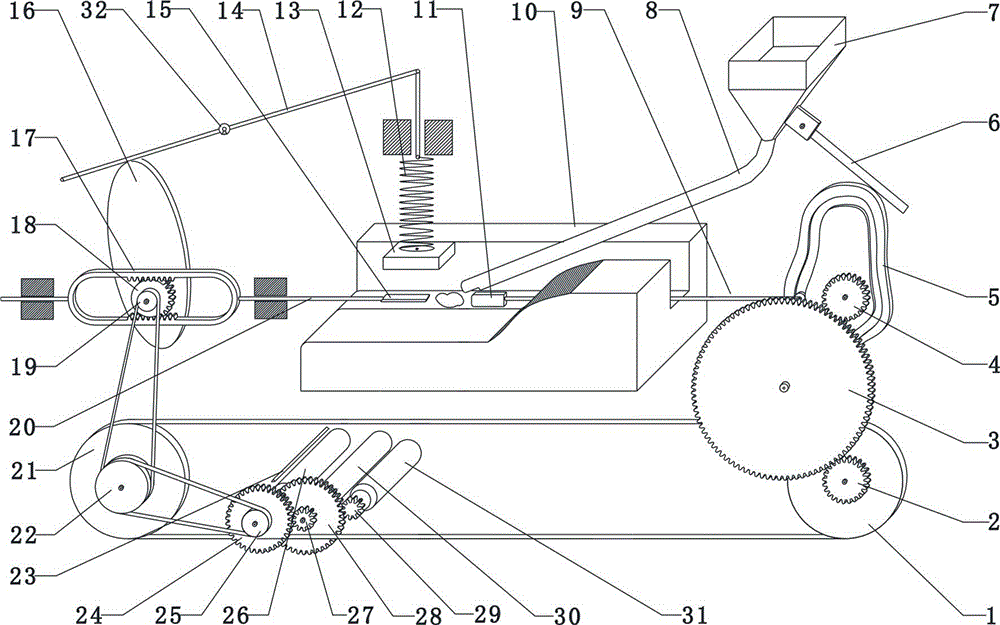

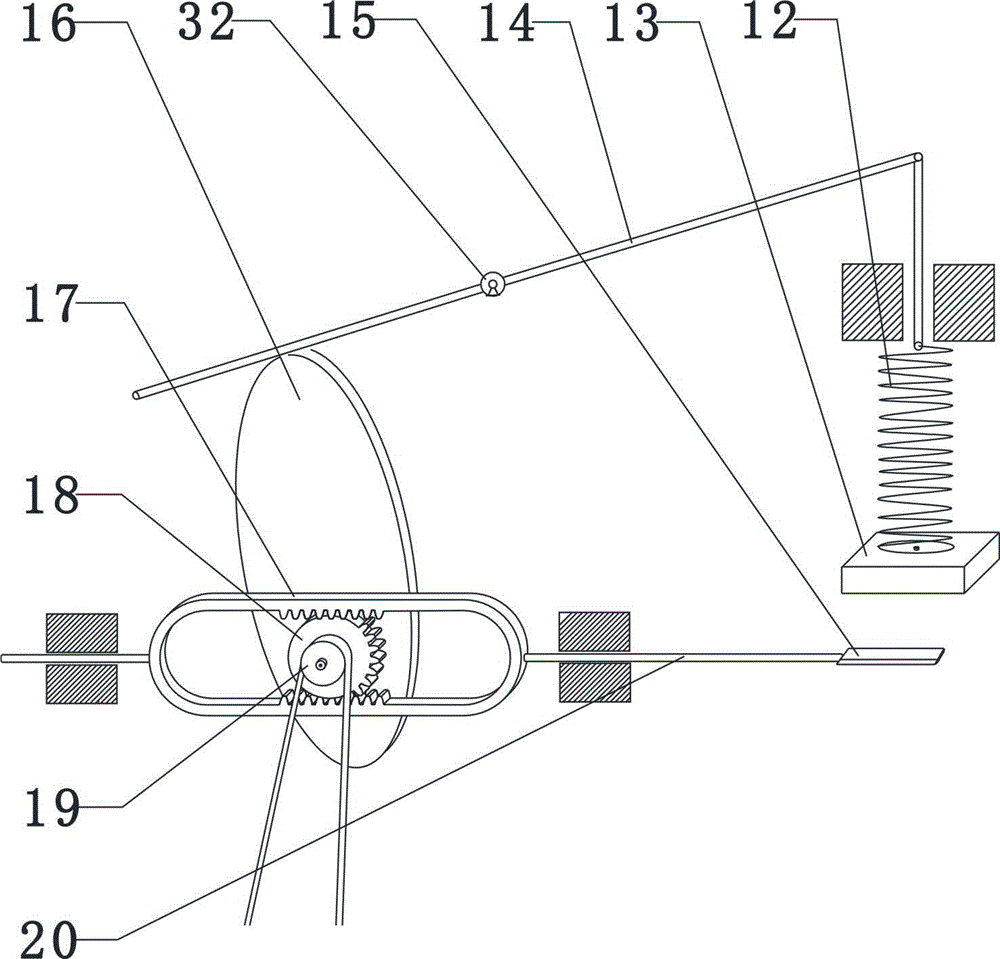

[0021] Such as Figure 1~Figure 5 As shown, an automatic bean peeling machine includes a feeding system, a bean pressing and peeling system, an extrusion peeling system and a casing. The overall size of the machine is about 1140mm*400mm*450mm.

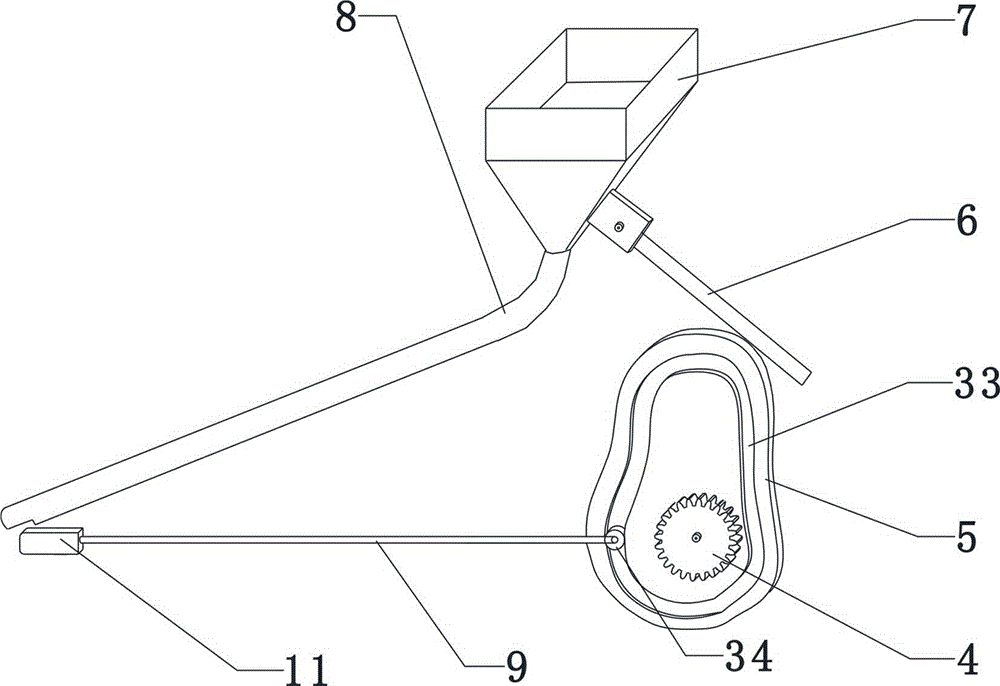

[0022] The feeding system includes a hopper 7, a pipeline 8, one end of the swing rod 6 is connected to the hopper 7, and the other end is in contact with the grooved cam 5, and the grooved cam 5 is fixedly connected to the first pinion 4; the groove of the grooved cam 5 Roller 34 is provided in groove 33, and roller 34 is hinged with push rod 9 one end, and push rod 9 other end is provided with push block 11; Change, the radius of curvature changes from large to small when retracting. The feeding system includes a workbench 10. The workbench 10 is provided with a groove 35, and the push rod 9 is located in the groove 35, so that the push rod 9 can realize reciprocating horizontal movement.

[0023] The bean pressing and peeling sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com