Fish killing machine

A fish-killing machine and rack technology, which is used in fish processing, fish cleaning/descaling, slaughtering, etc., can solve problems such as unfavorable physical and mental health of operators, high labor intensity of operators, and easy to suffer from frostbite on the palms, and achieves reliable removal. Scale, easy to implement, low loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

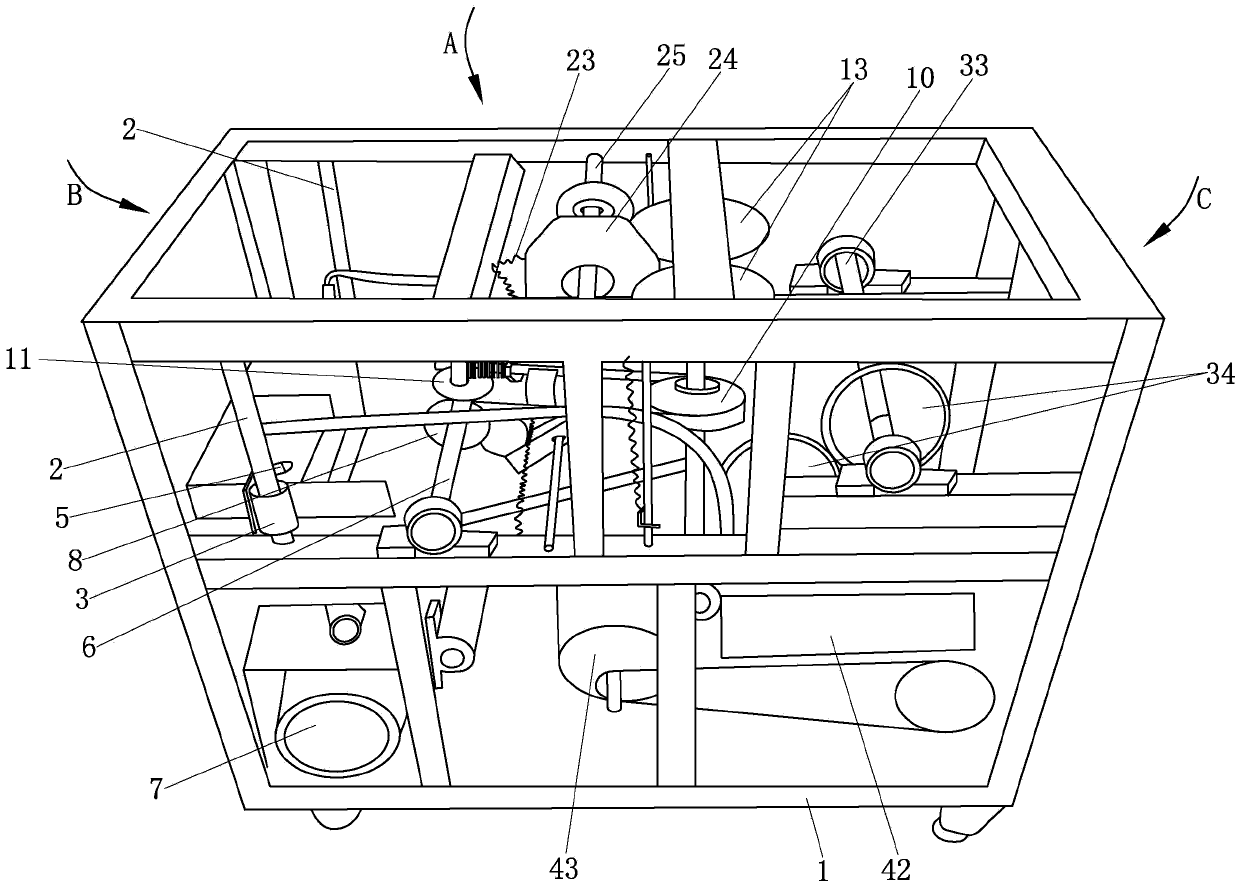

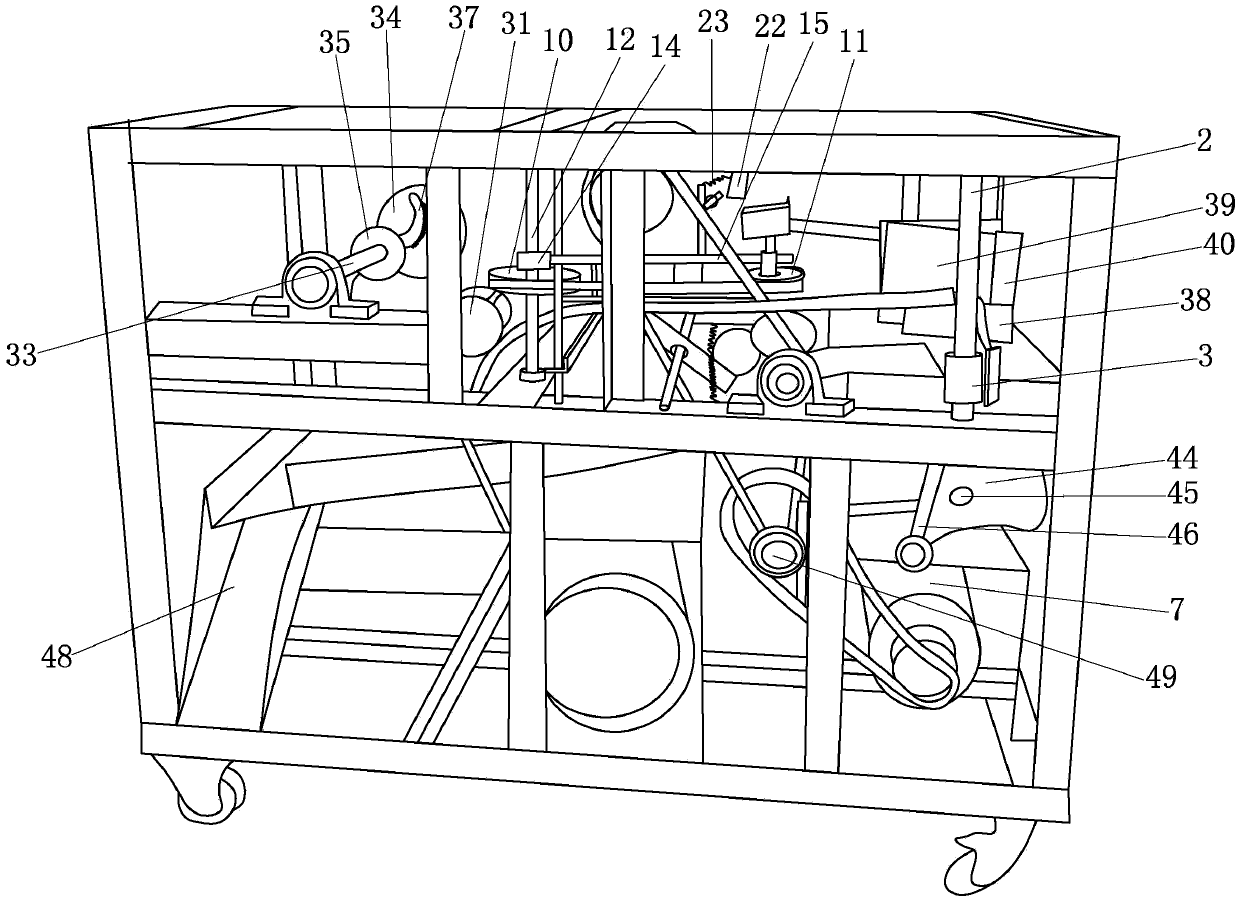

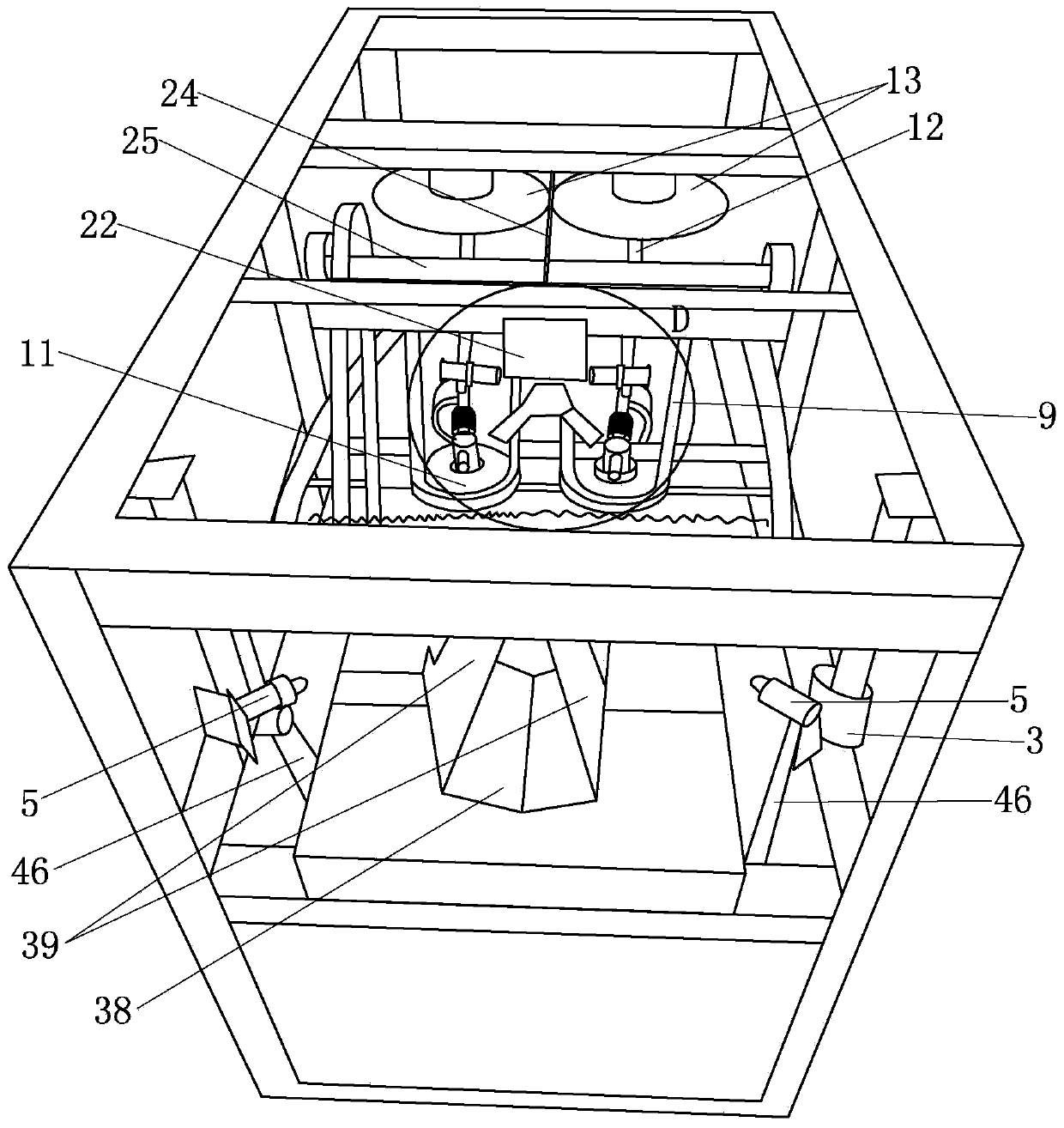

[0047] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0048] Such as Figures 1 to 9 As shown, a fish killing machine is mainly composed of a frame 1, a descaling mechanism, a traction mechanism, a back cutting mechanism and an intestine scraping mechanism. Wherein, the frame 1 is a multi-layer cuboid frame structure, and is welded by angle irons, and a universal wheel is respectively installed at the four corners of the bottom of the frame 1, so that it is convenient to move and transport the machine. fish machine. In addition, for the sake of aesthetics and protection of the internal structure, an outer cover can be provided outside the frame 1 .

[0049] The left end level at frame 1 is provided with a fish holding plate 38, and this fish holding plate 38 is " V " font structure, and its middle is low, front side and rear side are high, and left end and right end are open. Above the fish supporting plate 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com