Foldable combined traveling corn threshing drying tower

A corn threshing and drying tower technology, which is applied to threshing equipment, seeds preserved by drying, agricultural machinery and tools, etc., can solve the problems of high transportation cost, long processing cycle, immovability, etc., and achieve flexible movement and mechanical failure The effect of less, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

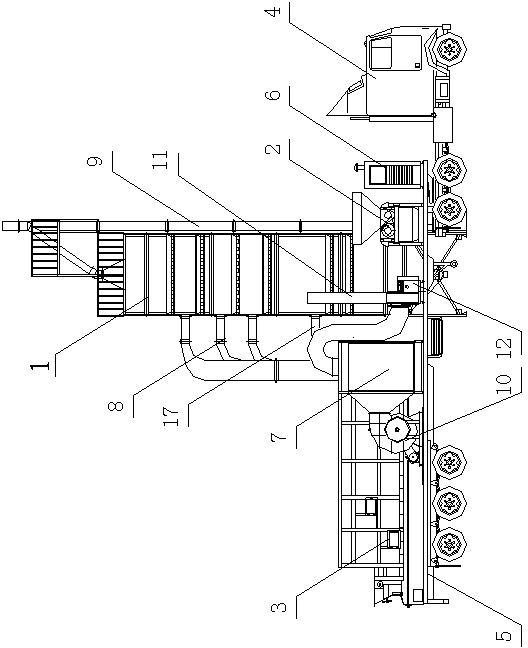

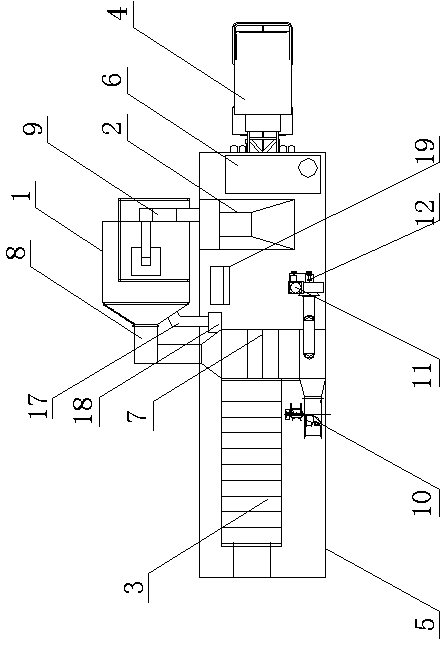

[0017] The foldable combined walking corn threshing drying tower of the present invention is composed of a drying tower 1, a threshing machine 2, a coal-fired hot air stove 3 and a locomotive I4, and the load pallet I5 of the locomotive I4 is sequentially provided with power generation Unit 6, threshing machine 2, heat exchanger 7 and coal-fired hot blast stove 3, the outlet end of coal-fired hot blast stove 3 is connected to heat exchanger 7, and the outlet of heat exchanger 7 is connected to the stand by more than one set of hot blast pipelines 8 The middle and upper parts of the drying tower 1 on the side of the load pallet I5 are connected, and the lower part of the drying tower 1 is provided with more than one set of cold air pipelines 17, which communicate with the cooling fan 18 fixed on the load pallet I5, and the outlet at the bottom of the threshing machine 2 is connected to the A hoist 9 is arranged between the top inlet of the drying tower 1, and the hoist 9 is fixe...

Embodiment 2

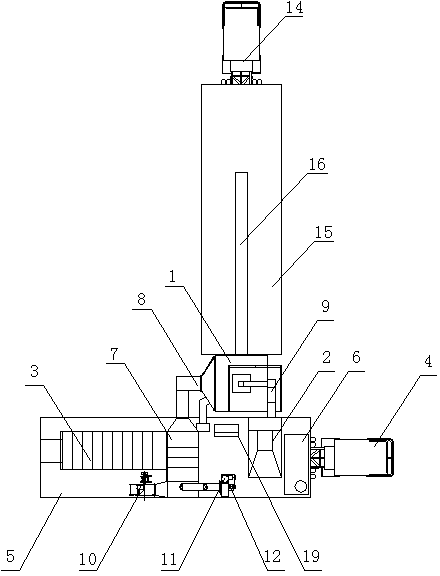

[0019] The foldable combined walking corn threshing drying tower of the present invention is composed of a drying tower 1, a threshing machine 2, a coal-fired hot air stove 3 and a locomotive I4, and a generator set 6 and a threshing machine are arranged on the load pallet I5 of the locomotive I4. Machine 2, heat exchanger 7 and coal-fired hot blast stove 3, the outlet end of coal-fired hot blast stove 3 is connected to heat exchanger 7; on the tail end of load pallet II 15 of locomotive II 14, the drying tower 1 is hinged by hinge 13 roots. The drying tower 1 is sequentially installed with interconnected material storage section, preheating section, drying section, slowing section, cooling section and discharge section from top to bottom, and there is a discharge outlet on the discharge section.

[0020] The outlet of the heat exchanger 7 on the load pallet I5 communicates with the middle and upper part of the drying tower 1 standing on one side of the load pallet I5 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com