Drive assembly with electric machine and motor vehicle having such drive assembly

A motor vehicle, electric drive technology, applied in the direction of motor vehicles, electric vehicles, hybrid vehicles, etc., can solve the problems of limited installation space, increased variation and related costs, expensive redesign process, etc., to reduce production and assembly costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

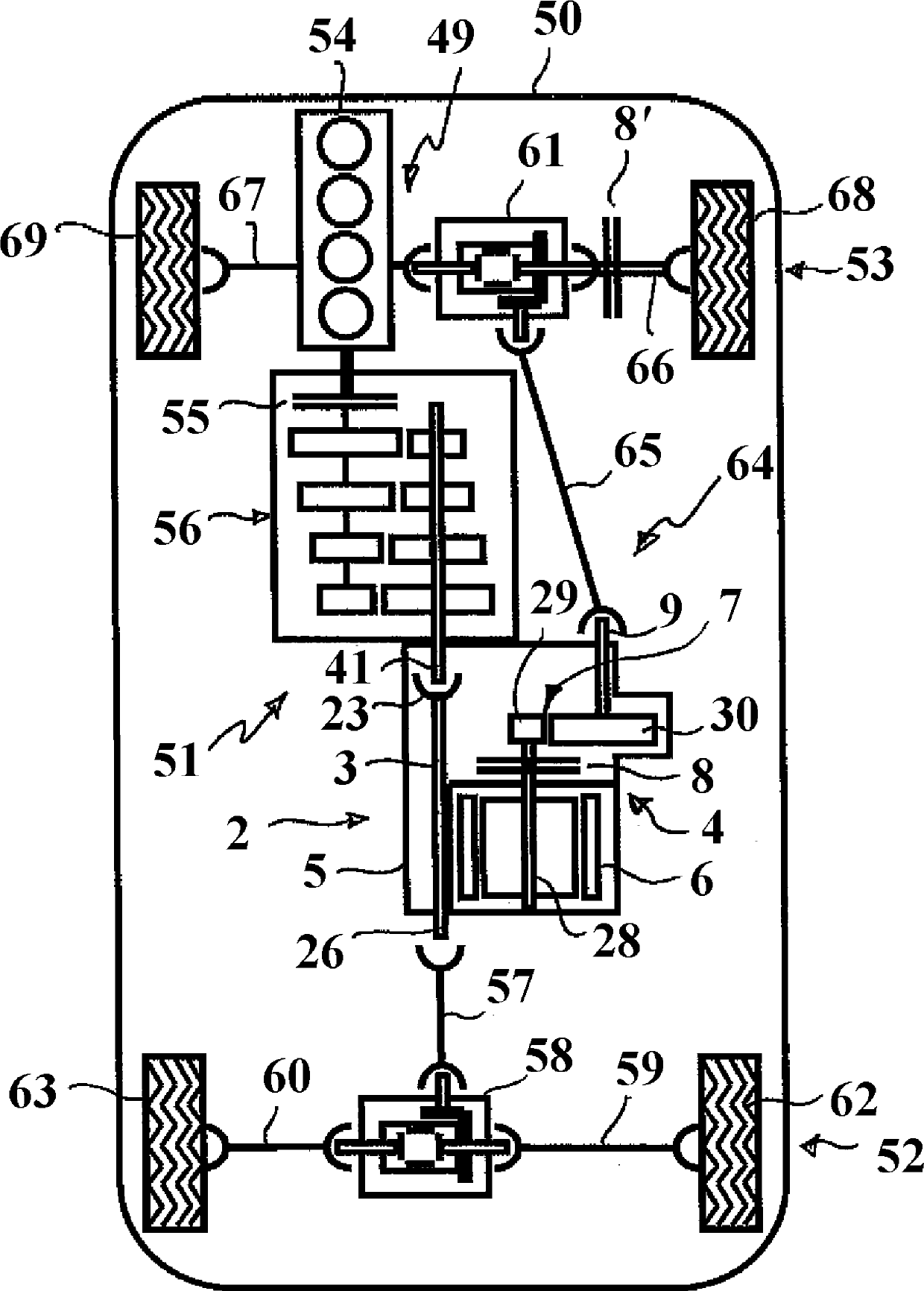

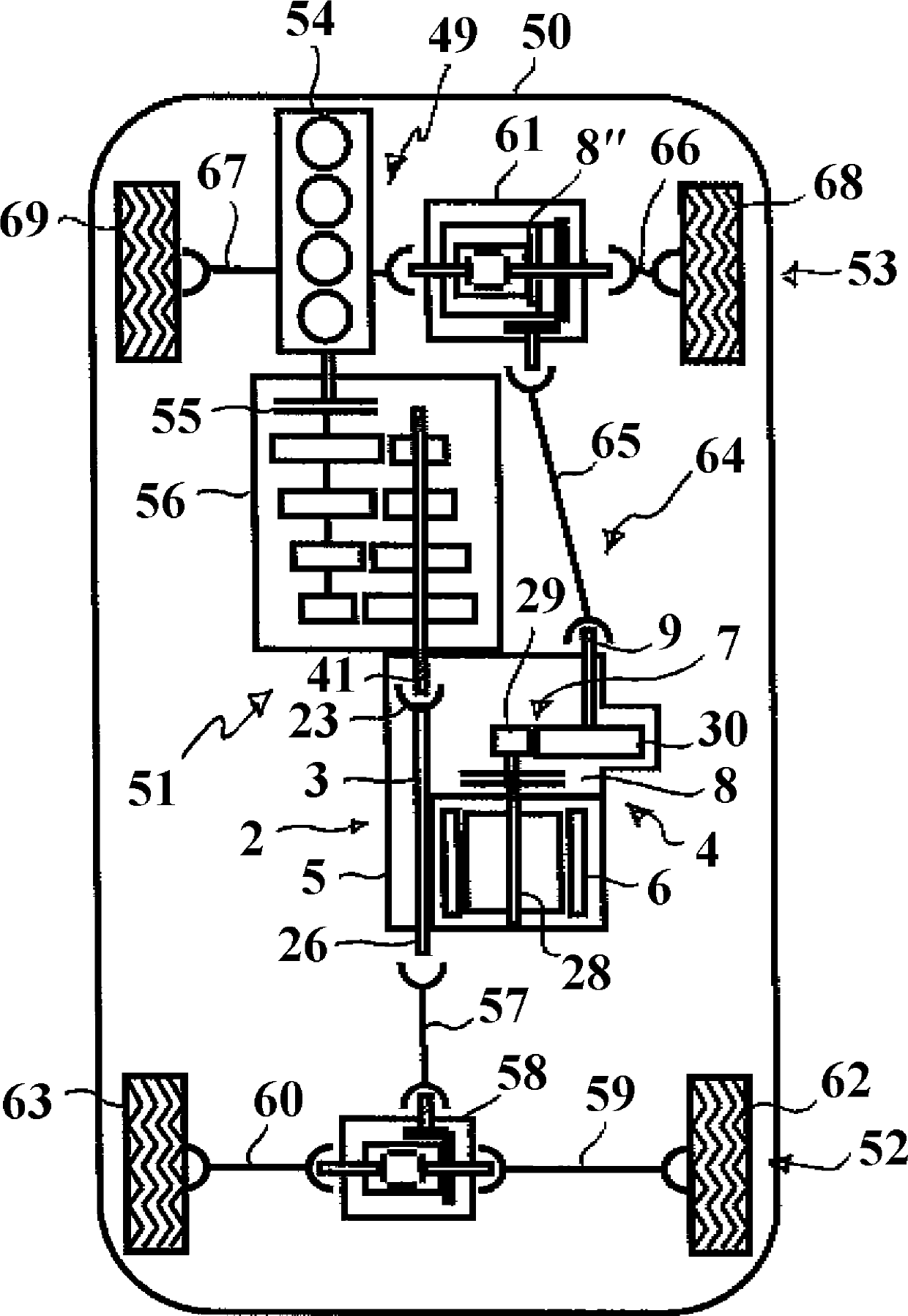

[0107] will be described together below Figure 1a ) to 1d) show the inventive electric drive assembly 2 . The electric drive assembly 2 may be used in a multi-axle, correspondingly all-wheel drive motor vehicle (not shown here) comprising a rear axle driven by an internal combustion engine as the primary drive, and a front axle which may optionally be driven . The rear axle is driven by a rear propeller shaft drivingly connected to a multi-speed transmission of the motor vehicle. The front axle is driven by a forward propulsion shaft, which is drivingly connected to the electric drive assembly 2 . The electric drive assembly 2 forming the auxiliary drive can be fixed to the multi-speed transmission of the motor vehicle, more specifically to the rear part of the multi-speed transmission.

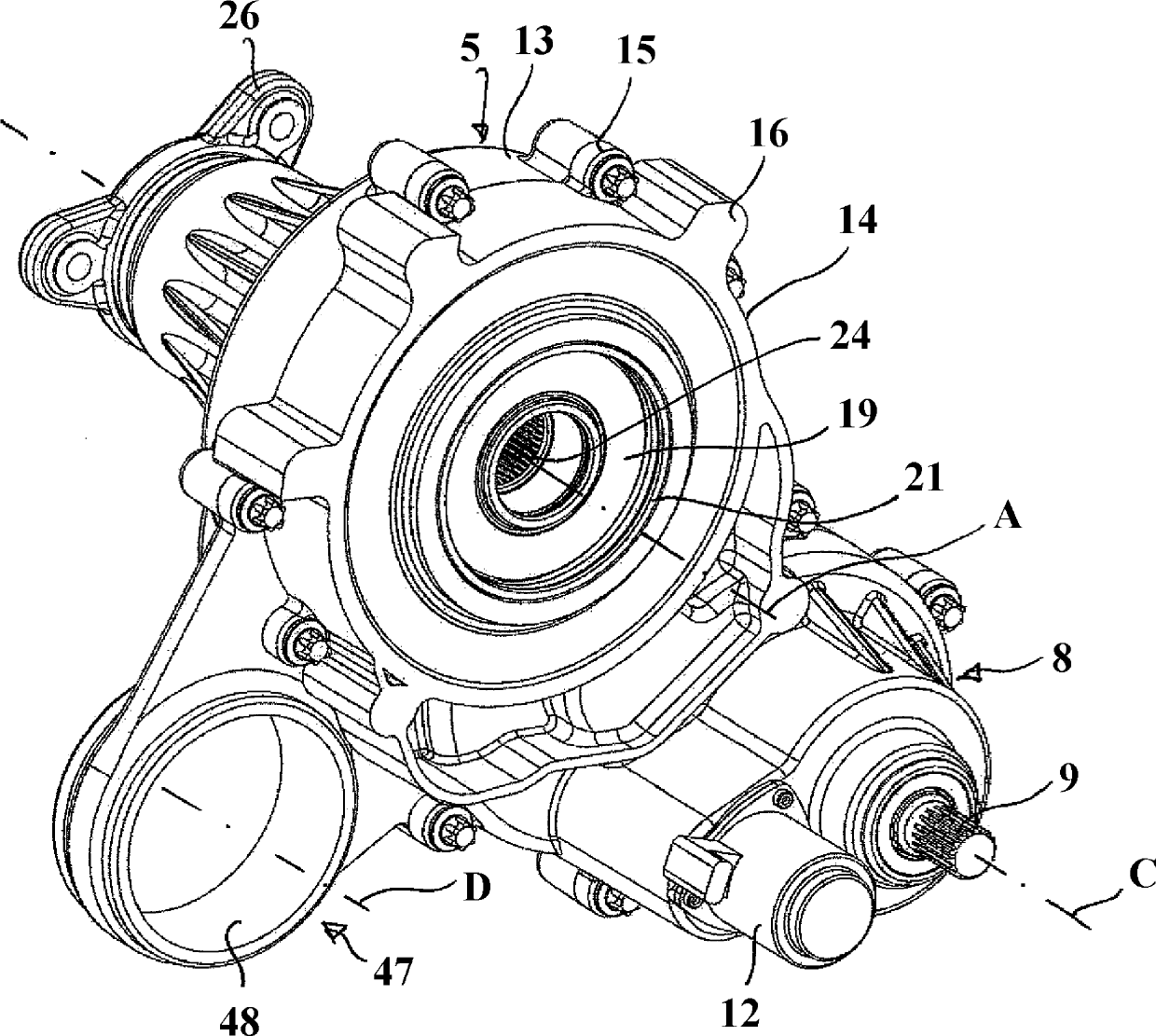

[0108] The electric drive assembly 2 comprises an electric motor 6 , a reduction gear 7 , a coupling 8 optionally externally controllable with an actuator, and a transmission shaft 9 . O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com