An assembly process of motor code disc

An assembly process and motor coding technology, which is applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of affecting the matching accuracy of the hole shaft, damaging the photoelectric encoder, and low accuracy of the encoding disc, so as to simplify manufacturing and maintenance Difficulty, achieving low-cost production, and the effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

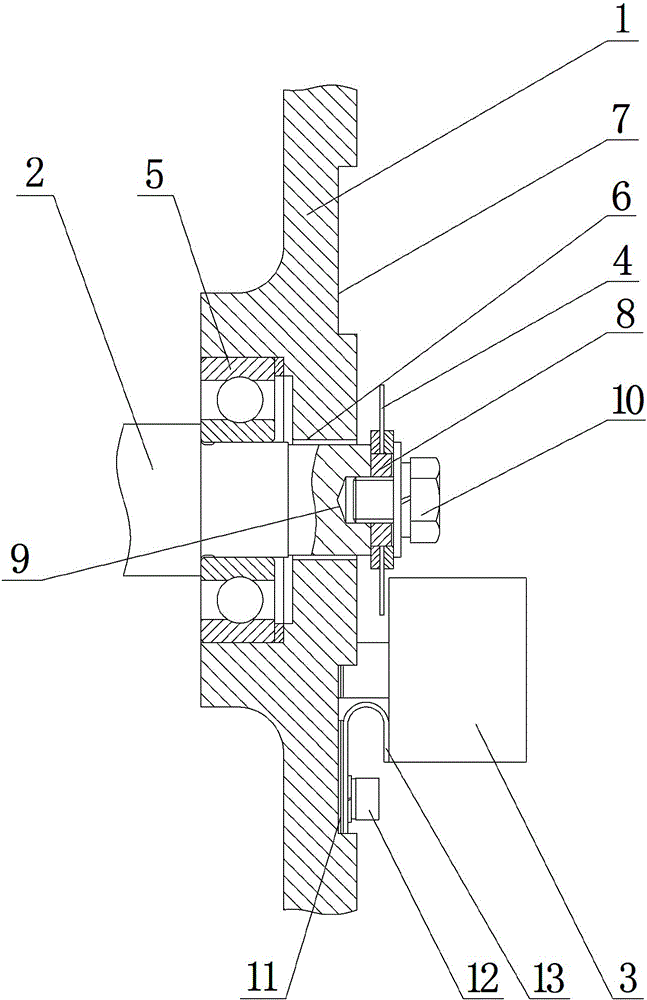

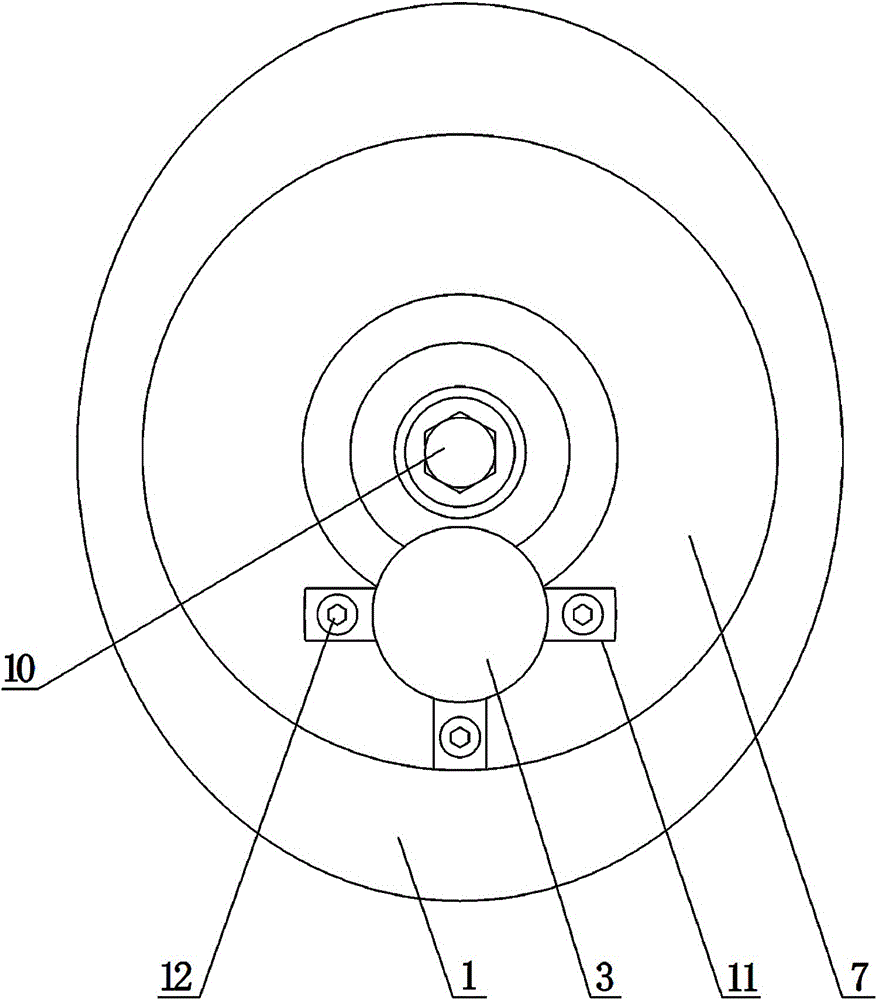

[0015] Such as figure 1 and figure 2 As shown, a motor encoder disk assembly process, which includes the following steps:

[0016] S1. First install the bearing 5 on the journal of the motor shaft 2, then pass the motor shaft 2 through the through hole 6, then install the bearing 5 in the bearing installation hole of the motor end cover 1 and fix the motor end cover 1 on the motor frame;

[0017] S2. To fix the grating disc, first set the grating disc 4 on the positioning shaft 8, and then tighten the locking bolt 10 to connect with the threaded hole 9. The locking bolt 10 limits the axial and radial movement of the grating disc 4, thereby realizing Fixed the grating disc 4;

[0018] S3, the fixing of photoelectric generator, first one side of three U-shaped adjusting gaskets 13 is all fixed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com