LED lamp core combined light source

A technology of LED wicks and combined light sources, which is applied to electrical components, electrical solid devices, circuits, etc., can solve the problems of few specifications, low yield, and difficult processing, and achieve stable quality, high yield, and product consistency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

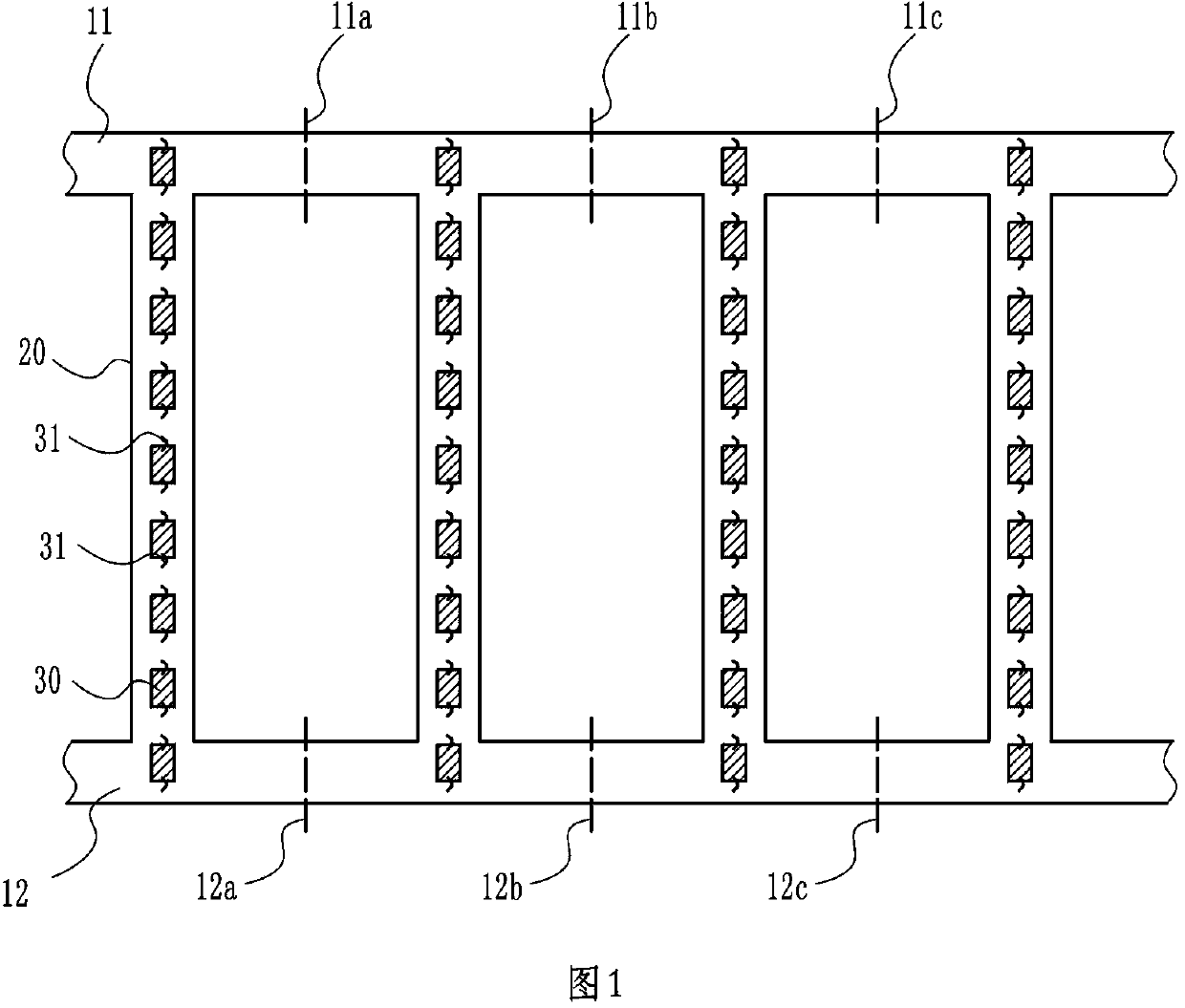

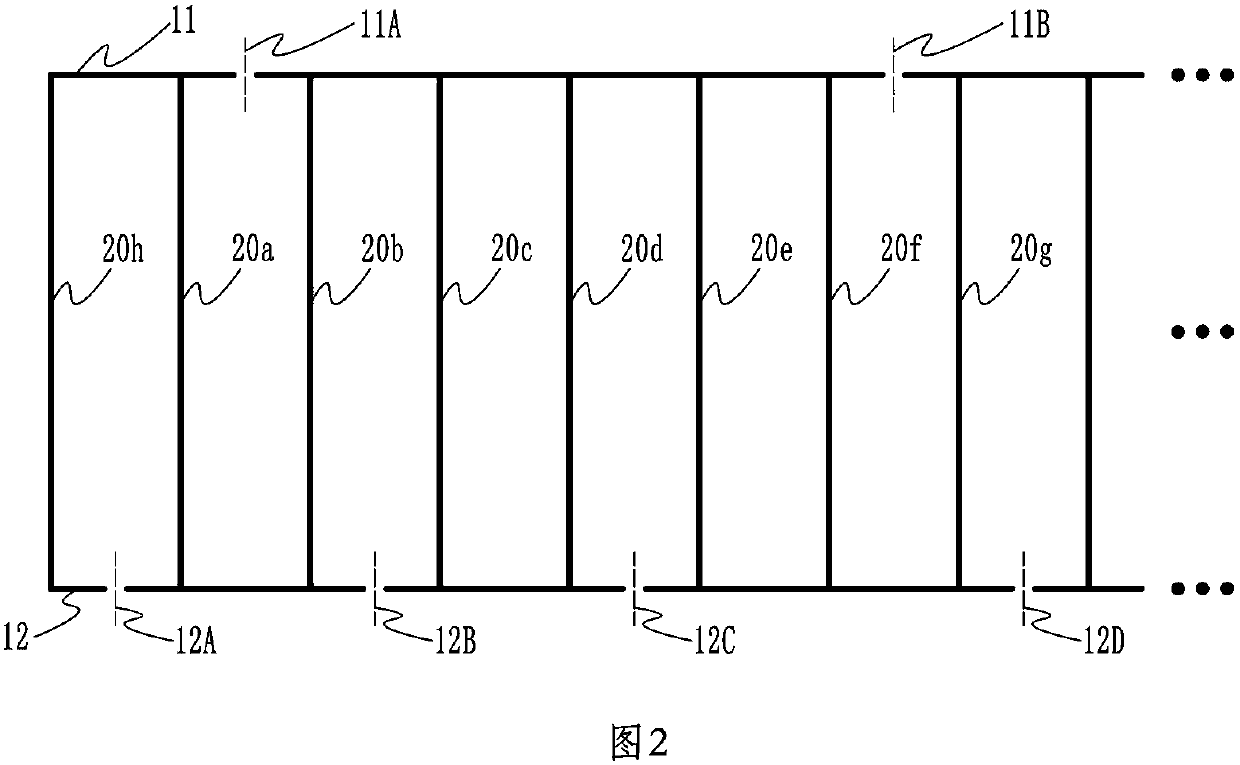

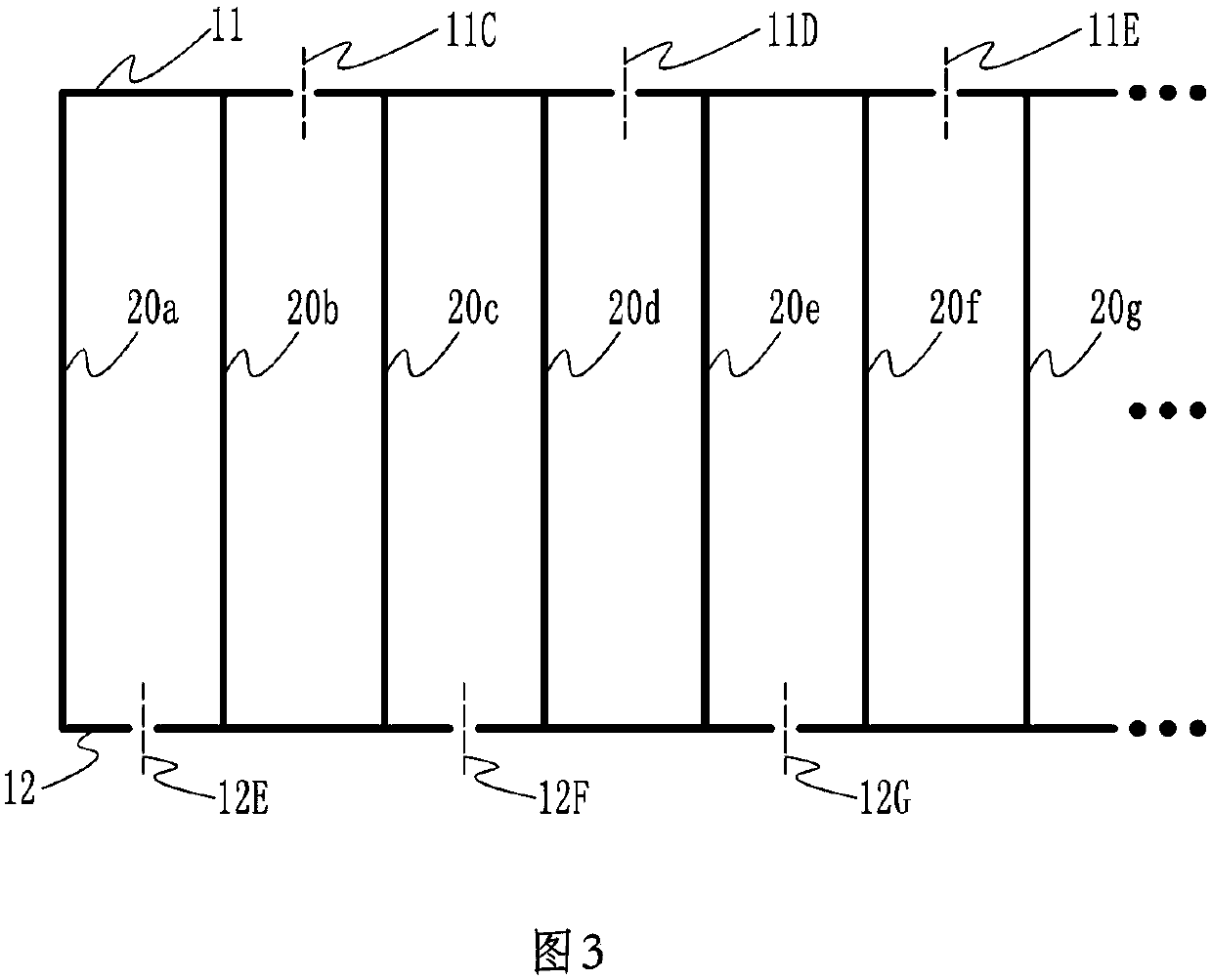

[0033] In order to save space, in this embodiment and other embodiments, the substrate will be represented by a solid line, and the structure of the LED unit and its electrode wires on the substrate will be omitted.

[0034] Such as figure 2 As shown, in this embodiment, the first electrical transverse portion 11 has upper insulating fractures 11A and 11B, and the second electrical transverse portion 12 has lower insulating fractures 12A, 12B, 12C, and 12D. There is an electrical longitudinal portion 20a between the upper insulation fracture 11A and the lower insulation fracture 12A; there is an electrical longitudinal portion 20b between the upper insulation fracture 11A and 12B; the upper insulation fracture 11A and the lower insulation fracture 12A and the lower insulation fracture 12B make the electrical longitudinal A series connection is formed between the portion 20h and the electrical longitudinal portion 20a and the electrical longitudinal portion 20b.

[0035] Ther...

Embodiment 2

[0038] Such as image 3 As shown, in this embodiment, the first electrical transverse portion 11 has upper insulating fractures 11C, 11D, 11E; the second electrical transverse portion 12 has lower insulating fractures 12E, 12F, 12G. In this embodiment, there is only one electrical longitudinal portion between adjacent upper and lower insulating breaks, so that the electrical longitudinal portions 20a, 20b, 20c, 20d, 20e, 20f, 20g are connected in series.

Embodiment 3

[0040] Such as Figure 4 As shown, in this embodiment, the first electrical transverse portion 11 has an upper insulating fracture 11F; the second electrical transverse portion 12 has lower insulating fractures 12H, 12I. In this embodiment, there are only two electrical longitudinal parts between the adjacent upper insulating fracture and the lower insulating fracture, so that the electrical longitudinal parts 20a, 20b, 20c, 20d, 20e, 20f, 20g are connected in parallel and then connected in series.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com