Novel intelligent electronic coil

An intelligent and electronic technology, applied to electromagnets, electromagnets with armatures, etc., can solve problems such as control failure, magnetic circuit hysteresis eddy current loss, and action time changes, so as to reduce size and cost, prolong service life, and improve reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings.

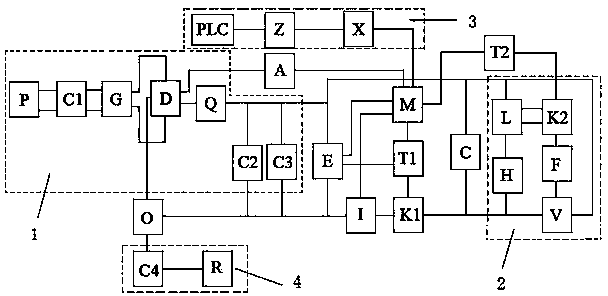

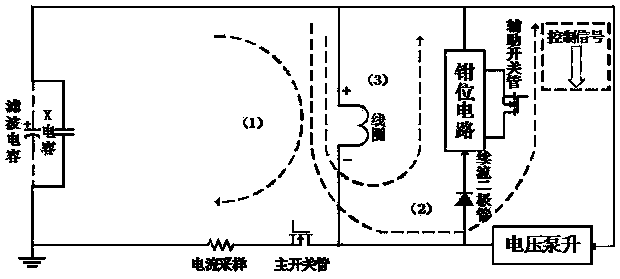

[0035] The present invention provides a new type of intelligent electronic coil, such as figure 1 It is characterized in that it includes: a micro-power processor M, a full-bridge rectifier circuit 1, an excitation coil C, a first switch tube K1 and a freewheeling demagnetization circuit 2; the micro-power processor M The first input end is connected to the output end of the voltage sampling circuit A, and the voltage sampling circuit A is used to sample the instantaneous value of the input voltage to ensure that the exciting coil C starts reliably and provides the required value for calculating the average value of the input voltage during the breaking process. The sampling voltage ensures reliable disconnection of the exciting coil C; the input end of the voltage sampling circuit A is connected to the first output end of the full-bridge rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com