On-line detection method of continuous casting billet surface longitudinal crack

A detection method and technology for longitudinal cracks, applied in the field of continuous casting of iron and steel metallurgy, can solve the problems of economic loss, casting billets judged as waste products, etc., and achieve the effect of eliminating interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

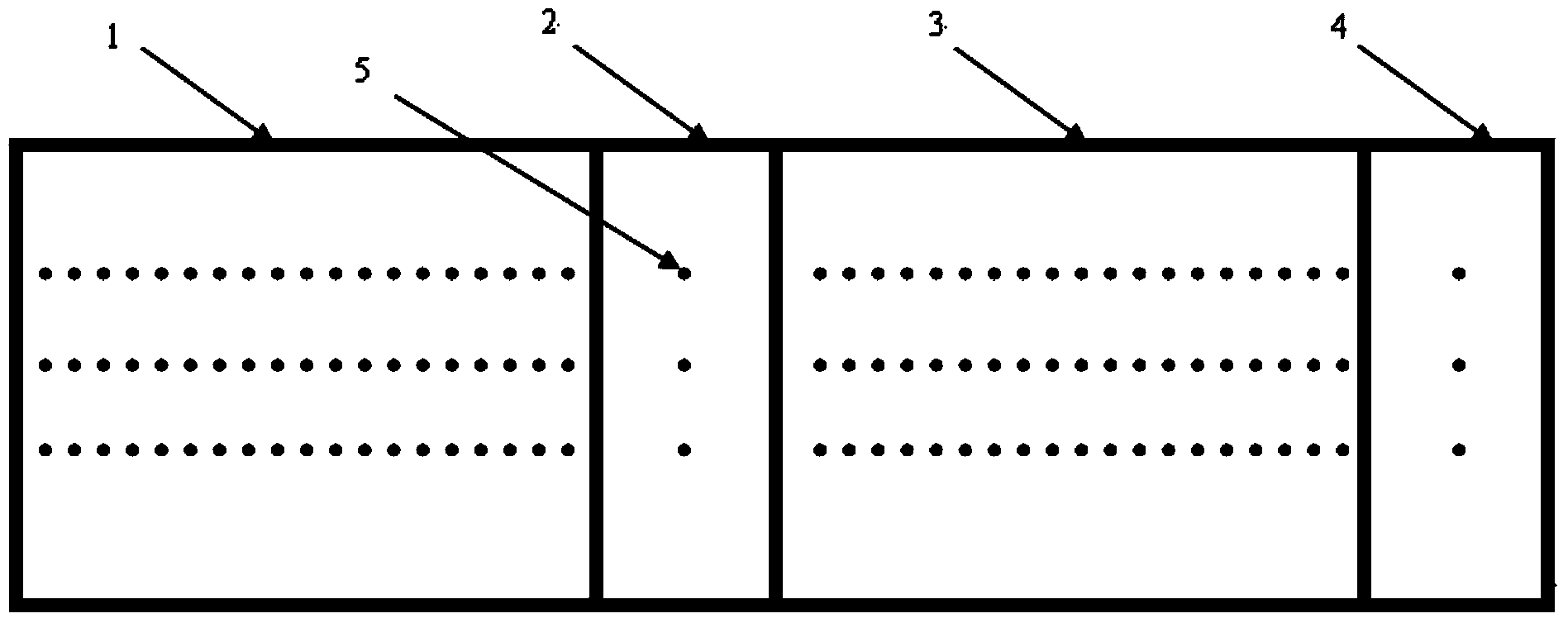

[0065] figure 1 It is a block diagram of visual prediction of continuous casting slab longitudinal cracking. Depend on figure 1 It can be seen that the visual detection method of continuous casting slab longitudinal cracks based on computer vision is divided into the following four parts: crystallizer copper plate temperature visualization, cold spot area segmentation, cold spot area feature information extraction, longitudinal crack feature identification and prediction.

[0066] The present invention will be further described in detail through specific embodiments below in conjunction with the accompanying drawings.

[0067] The first step, crystallizer copper plate temperature and its temperature difference visualization

[0068] figure 2 It is a schematic diagram of copper plate expansion and thermocouple arrangement of wide-face and narrow-face crystallizers. The length of the mold of the continuous casting machine is 900mm, and it is composed of four copper plates, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com