Mechanism for detecting standard fastener

A detection standard and fastener technology, applied in the field of detection devices, can solve the problems of inability to detect thread pitch, less detection mechanisms, and narrow adaptability, and achieve the effects of good stability and firmness, easy processing and production, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

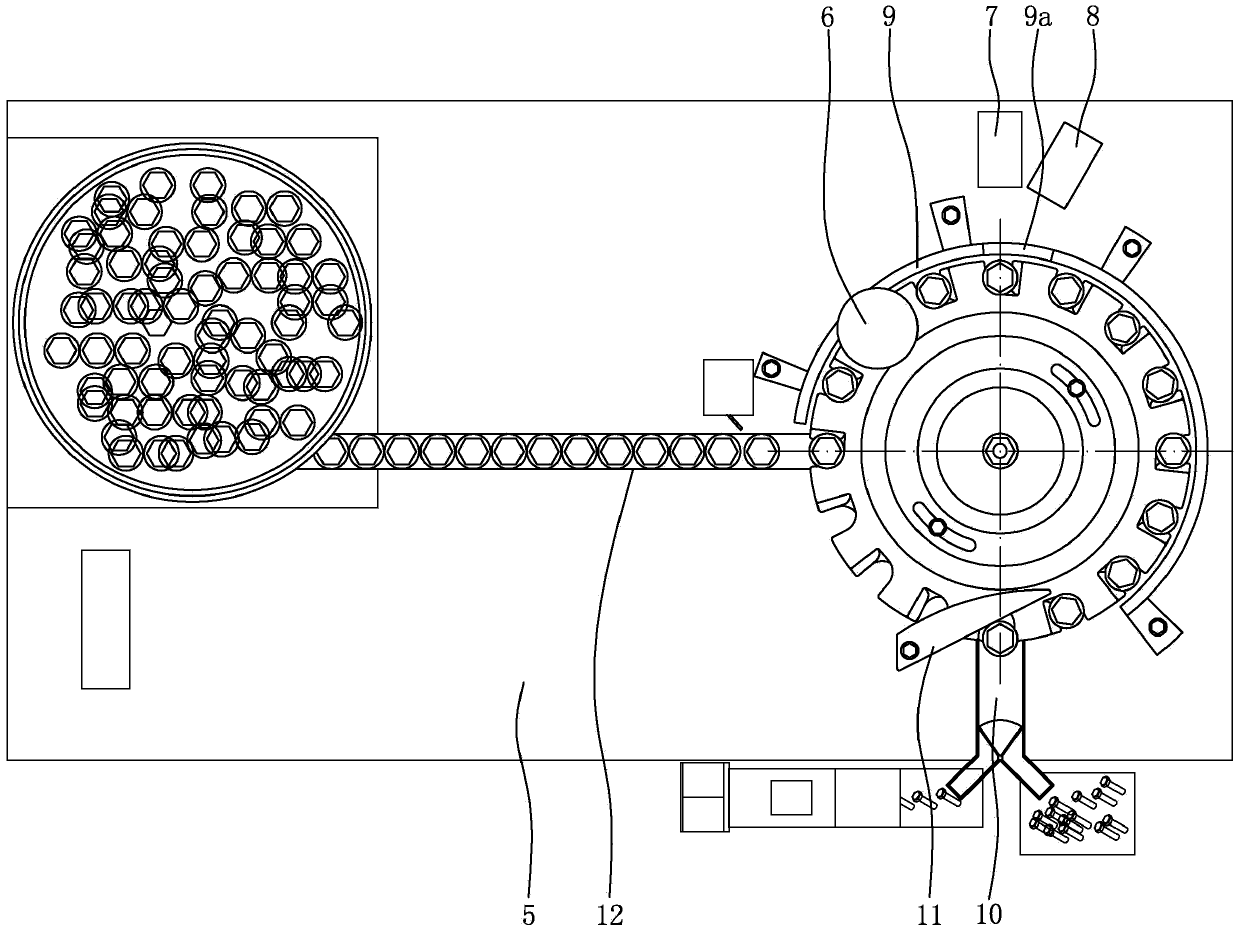

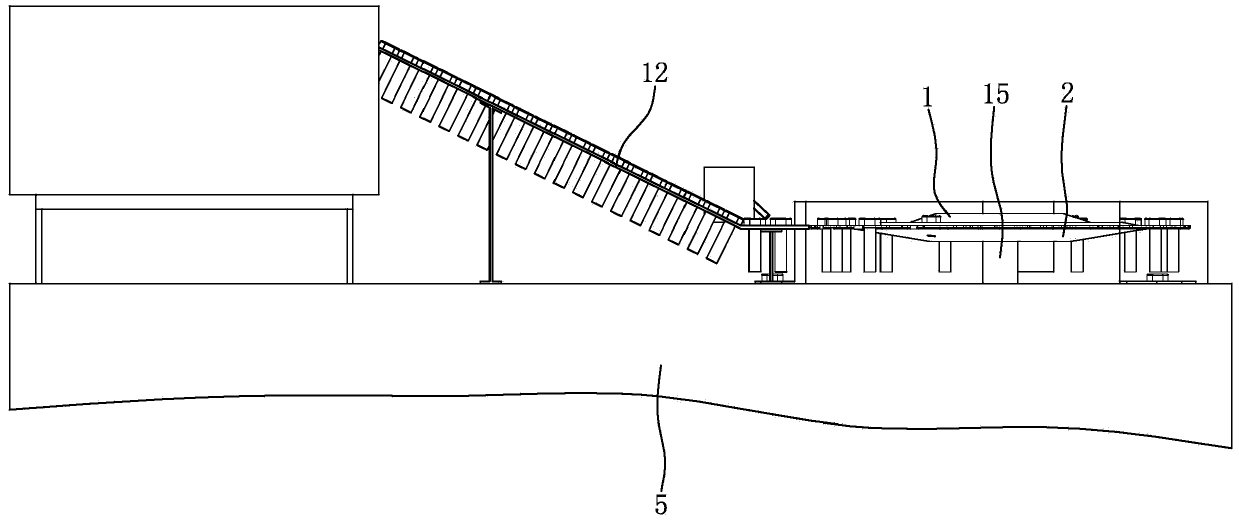

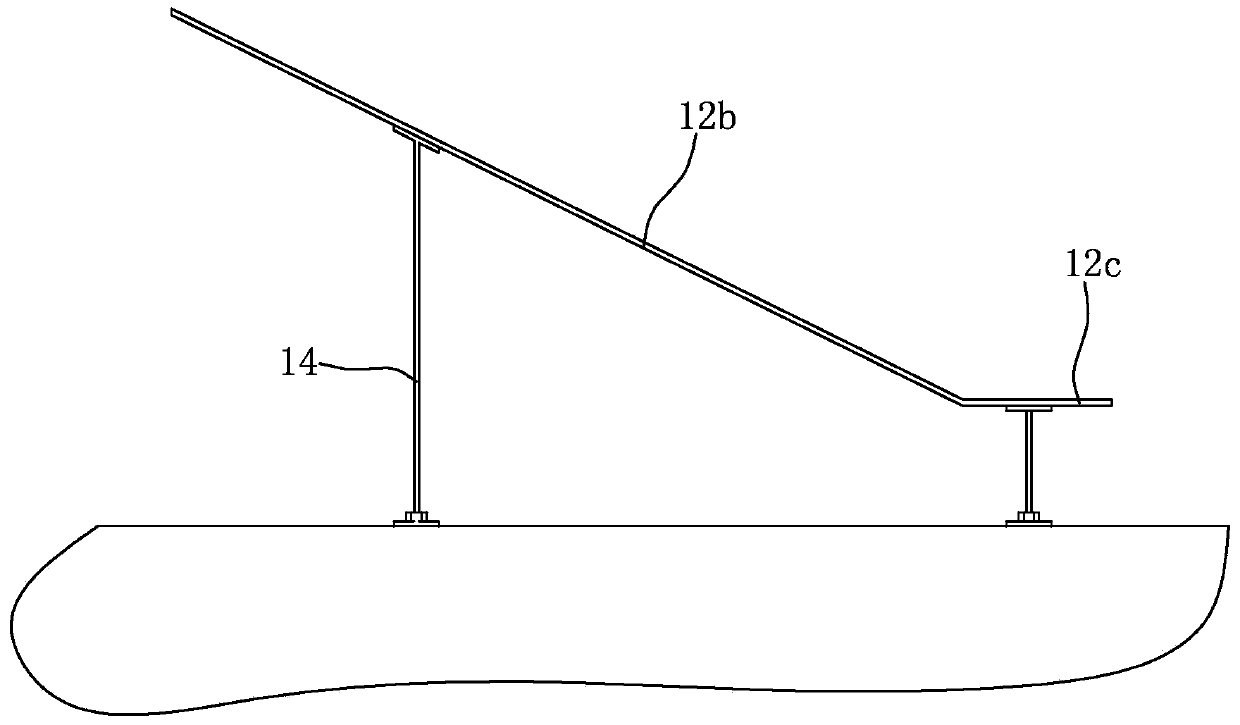

[0037] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0038] Such as figure 1 , figure 2 , Figure 5 , Image 6 , Figure 7 , Figure 8 As shown, the indexing turntable is arranged on the machine platform 5 and consists of a moving plate 1 and a fixed plate 2 . The moving plate 1 and the fixed plate 2 are disc structures with equal diameters, and the moving plate 1 is located directly above the fixed plate 2 . The middle part of the top surface of the moving disk 1 is integrally formed with a stepped boss with a small upper part and a larger lower part; The surfaces are fitted together, and the moving plate 1 and the fixed plate 2 are connected by two fastening bolts evenly distributed on the circumference. The hole on the moving plate 1 for the fastening bolts to pass through is an arc-shaped hole 1c, and the hole 1c The center of circle is on the axis line of moving disk 1. A stepper motor 15 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com