Multi-section intermittent microwave hot-air coupling drying equipment

A technology of microwave hot air and drying equipment, which is applied in the direction of progressive dryers, lighting and heating equipment, and heating to dry solid materials, etc., which can solve the problems of reducing product quality, increasing the absorption load of microwave drying boxes, and uneven wind speed. Product quality, intermittent ratio can be adjusted continuously, and drying rate can be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

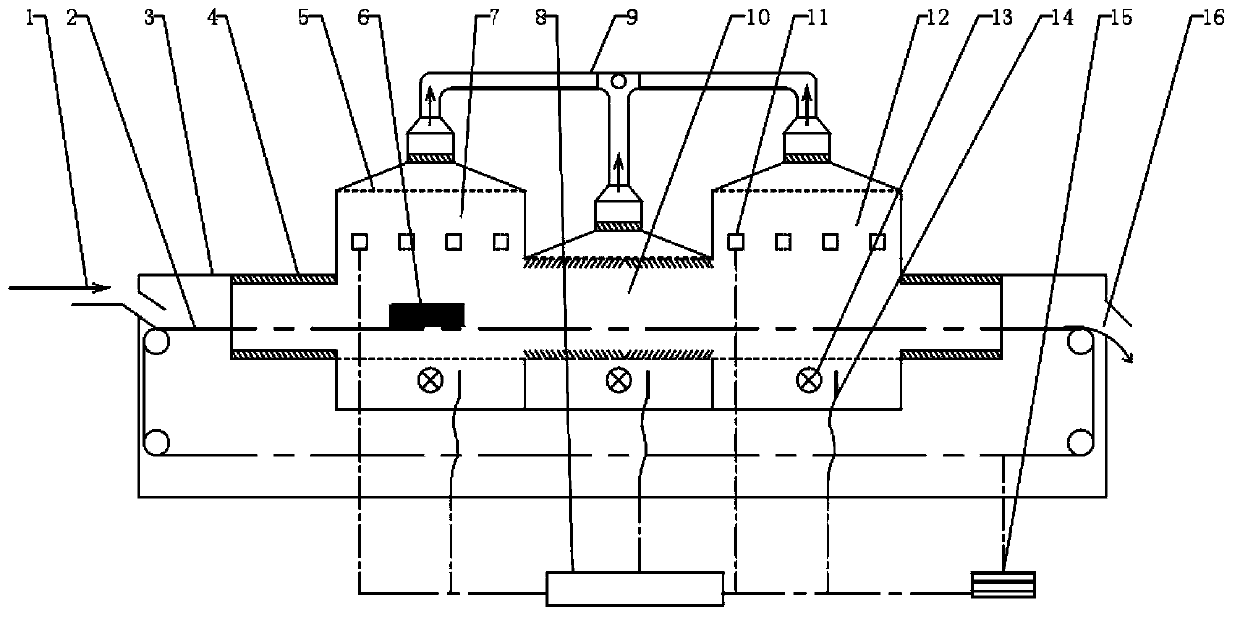

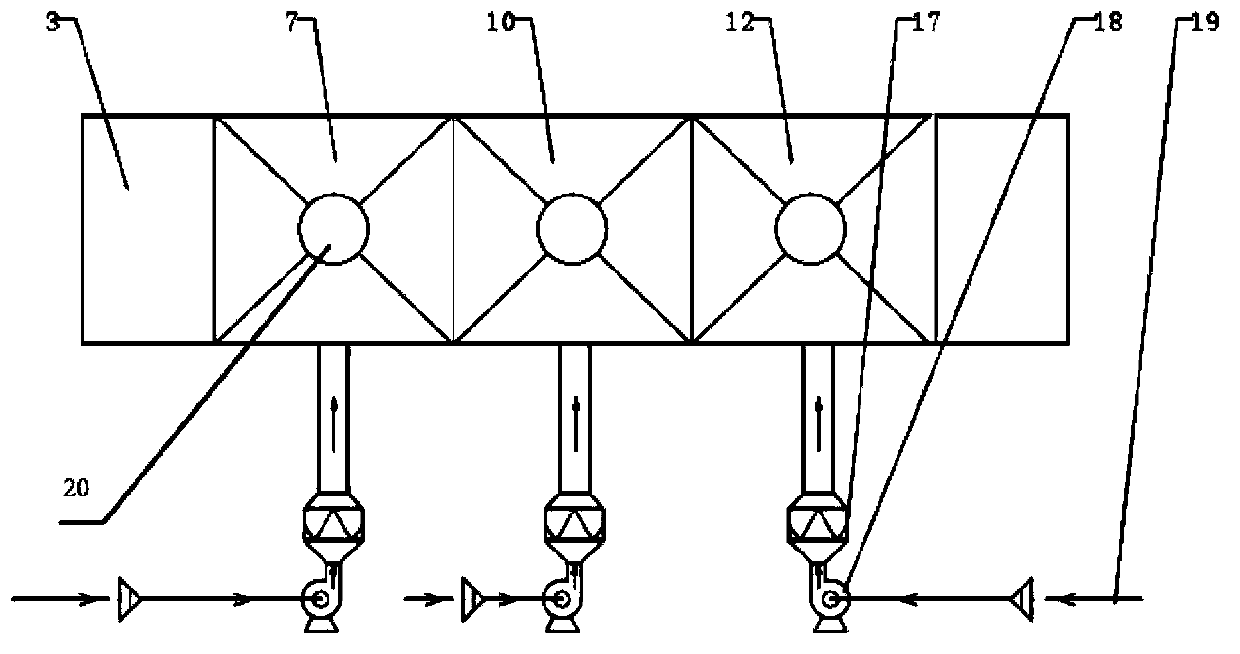

[0049] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings.

[0050] like figure 1 and figure 2 Shown are the cross-sectional view and top view of the multi-stage intermittent microwave hot-air coupling drying equipment of the present invention, wherein the top view does not include the dehumidifying device 9 . The multi-stage intermittent microwave hot air coupling drying equipment includes a shell 3, one end is a material inlet 1, and the other end is a material outlet 16; the drying equipment also includes a material conveying device, a multi-stage drying chamber, a hot air device, and a moisture discharge Device 9 and control device.

[0051] Wherein, the material conveying device includes a conveyor belt 2 for conveying materials, the conveyor belt 2 is an endless belt, one end is located at the material inlet 1, and the other end is located at the material outlet 16, and passes thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com