A solution dehumidification unit

A solution dehumidification and unit technology, applied in the direction of refrigerators, adsorption machines, refrigeration and liquefaction, etc., can solve the problems of high energy consumption, achieve the effects of reducing energy consumption, improving efficiency, and improving social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

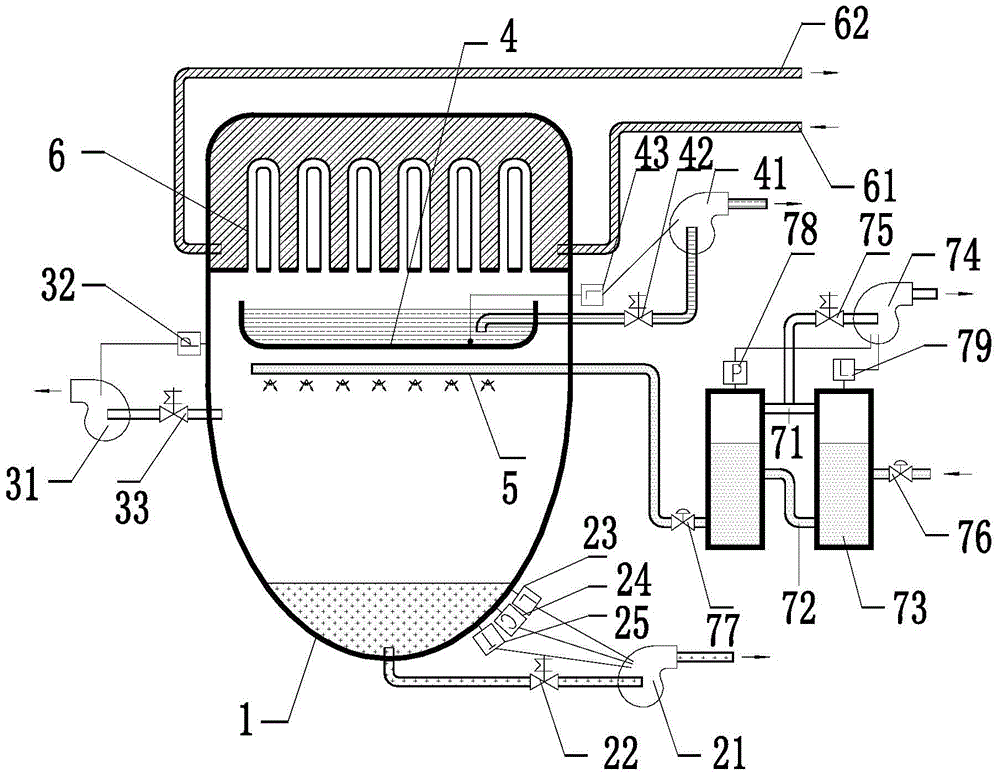

[0039] The present invention as figure 1 As shown, the solution dehumidification unit includes a vacuum boiling evaporation chamber 1, a concentrated solution pump 21, a gas-liquid separation device, an evaporation chamber vacuum pump 31, an evaporation chamber vacuum pressure gauge 32 and a control circuit; Condensing device, condensed water collecting pan 4 and dilute solution sprayer 5 are arranged, the condensing device is arranged on the top of vacuum boiling evaporation chamber 1, the condensed water collecting pan 4 is arranged under the condensing device, and the dilute solution sprayer 5 is arranged on Below the condensed water collection tray 4; the bottom of the vacuum boiling evaporation chamber 1 is provided with a concentrated solution outlet, the concentrated solution outlet is connected with the concentrated solution p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com