Multi-well wellhead dosing device with backflow self-protection multichannel solenoid valve terminal

A technology of dosing device and solenoid valve, which is applied in wellbore/well components, cleaning equipment, earthwork drilling and mining, etc., and can solve problems such as inconvenient maintenance, rising solenoid valve pressure, and pipeline blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

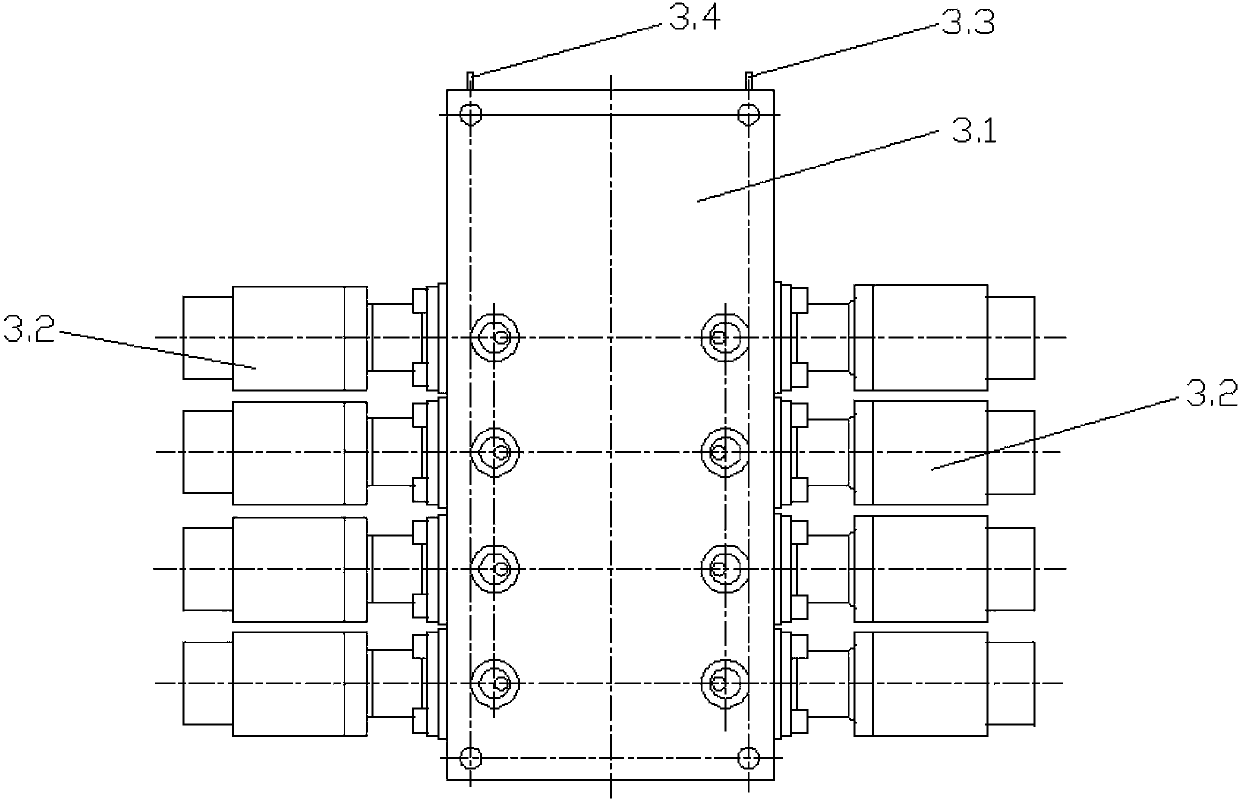

[0043] see figure 1 As shown, the embodiment of the present invention provides a multi-well wellhead dosing device with backflow self-protection multi-way electromagnetic valve island, which controls the opening and closing of the backflow self-protection of the medicinal liquid. The device at least includes: a dosing box 1, a control Cabinet 2, multi-channel solenoid valve island 3, high-pressure metering dosing pump 4, pressure gauge 5, liquid inlet pipeline 6, liquid return pipeline 7 and other parts and related pipelines, and related control circuits; specifically, the dosing box 1 A control cabinet 2 is arranged on the front side, and a multi-channel electromagnetic valve island 3 and a high-pressure metering dosing pump 4 are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com