Built-in reel device

A pipe reel, built-in technology, applied in the field of built-in pipe reels, can solve the problems of not being able to keep the cooling pipe clean at any time, heavy labor, and inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with specific embodiment, further set forth the present invention:

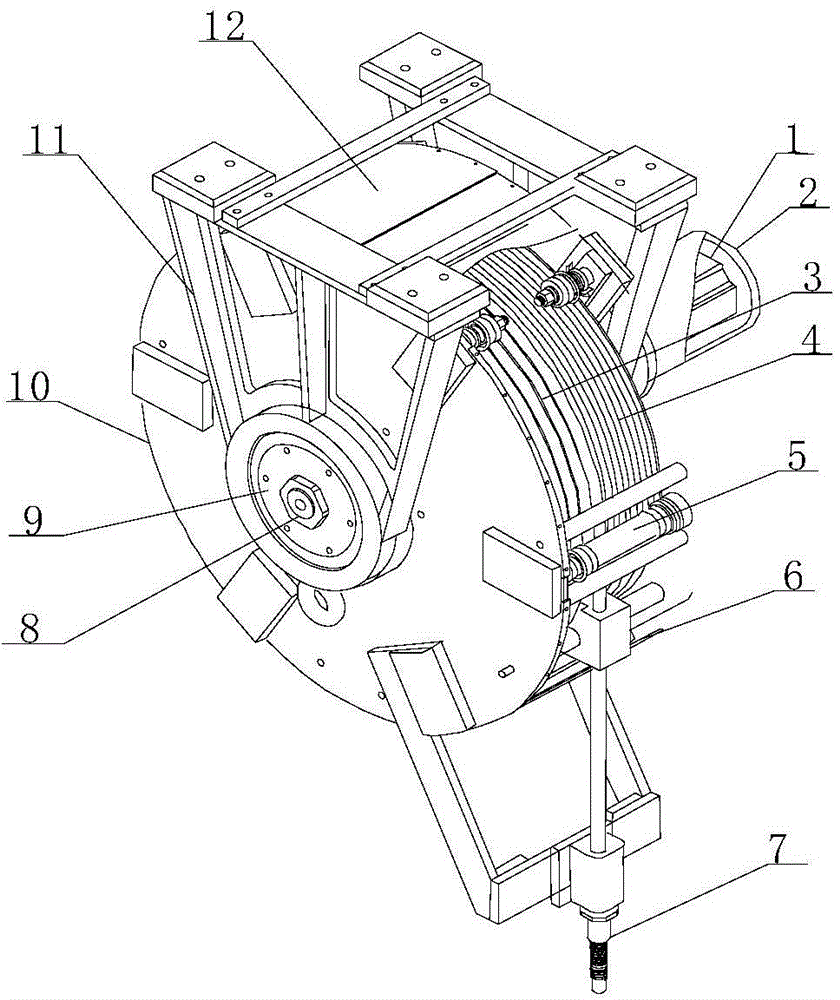

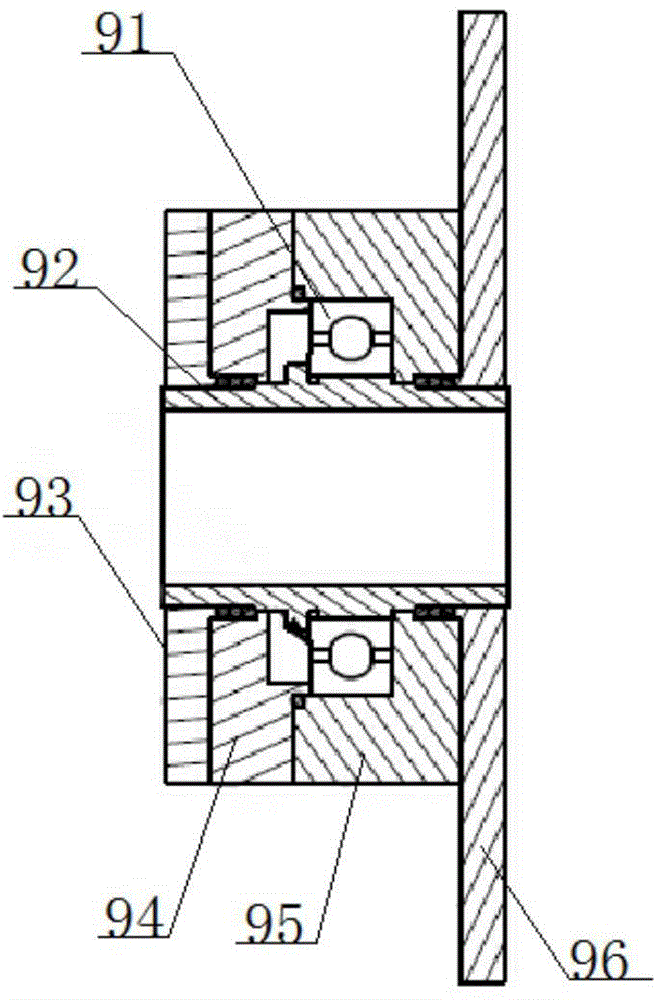

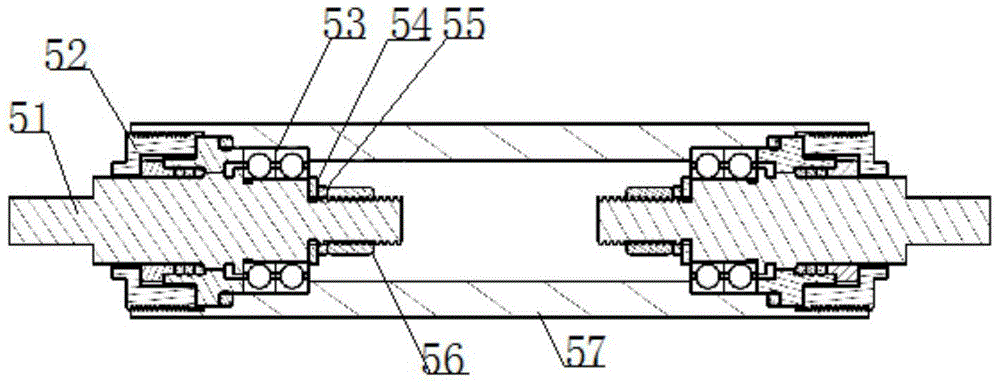

[0016] Such as figure 1 , 2 As shown in , 3, a built-in reel of the present invention includes a rotating shaft 8, a reel fixing frame 11, a support plate 10, a sealed bearing body 9, a core roller 4, a high-pressure water pipe 3, a motor 1 and a speed reduction device, The motor 1 is provided with a sealing cover 2; the reduction device can be a planetary gear reducer; the core roller 4 is connected and sleeved on the rotating shaft 8 by a bearing, and is fixed by the reel fixing frame 11 and the support plate 10; the core roller 4 is designed as With a wedge-shaped spiral groove, when the high-pressure water pipe 3 is pushed out, the water pipe is pushed out by the extrusion friction force between the high-pressure water pipe 3 and the wedge surface; the outer part of the high-pressure water pipe 3 is provided with an outer casing 7, and the outer surface of the outer casing 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com