Wall grooving machine

A slotting machine and wall technology, applied in the direction of construction, building construction, etc., can solve the problems of dust splashing, adverse effects on the health of construction workers, single-piece masonry and cutting, etc., to achieve a wide range of use, waterproof and dust removal effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

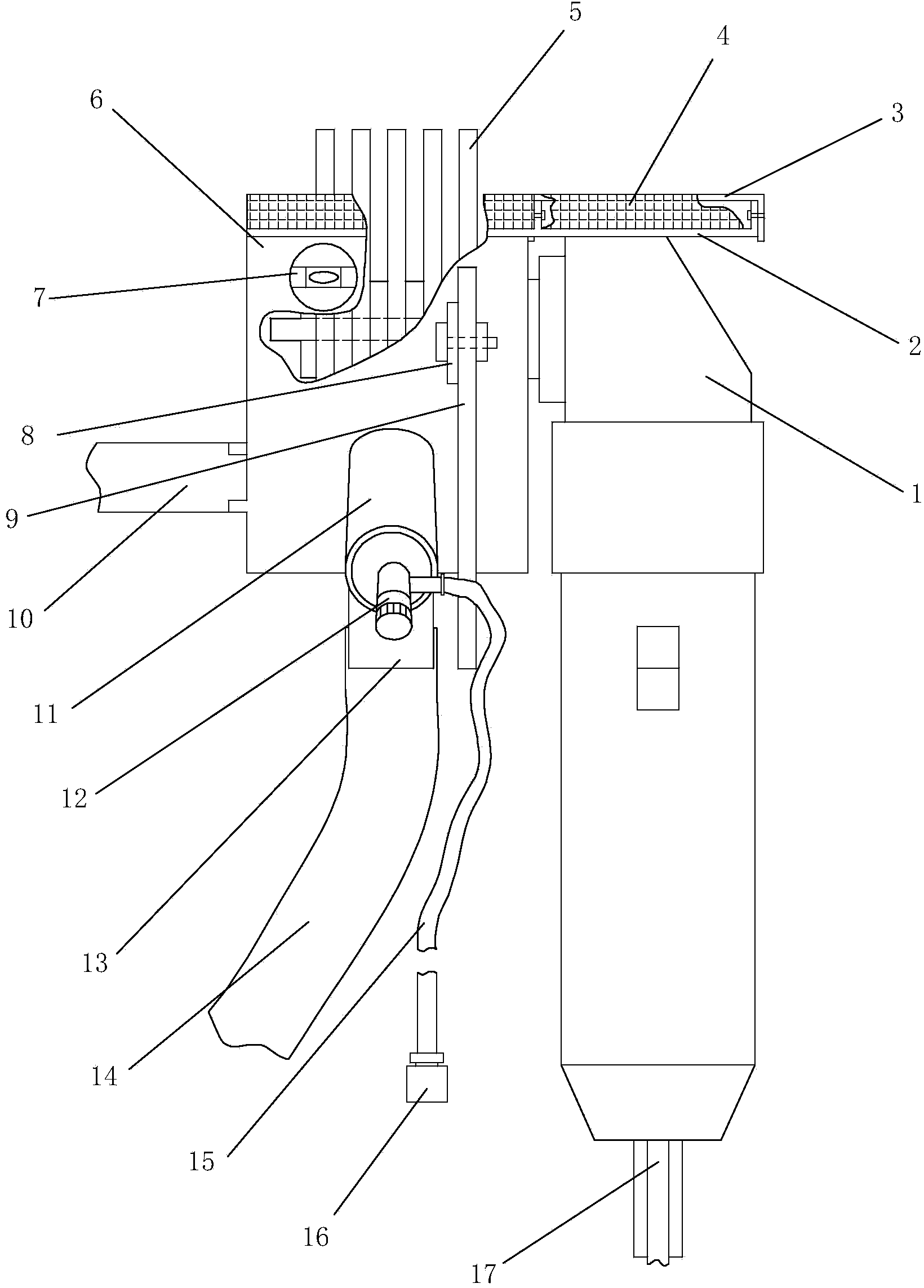

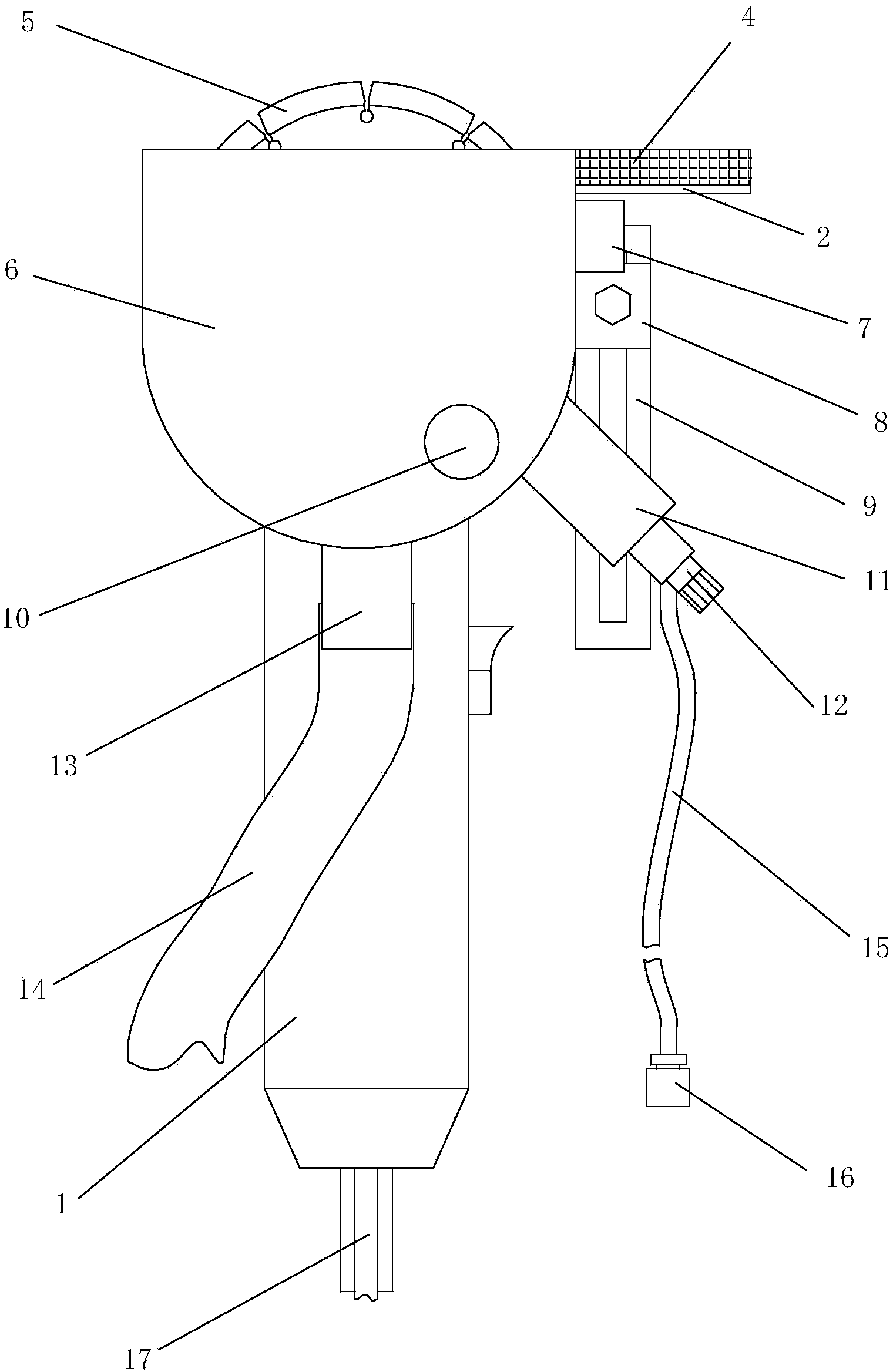

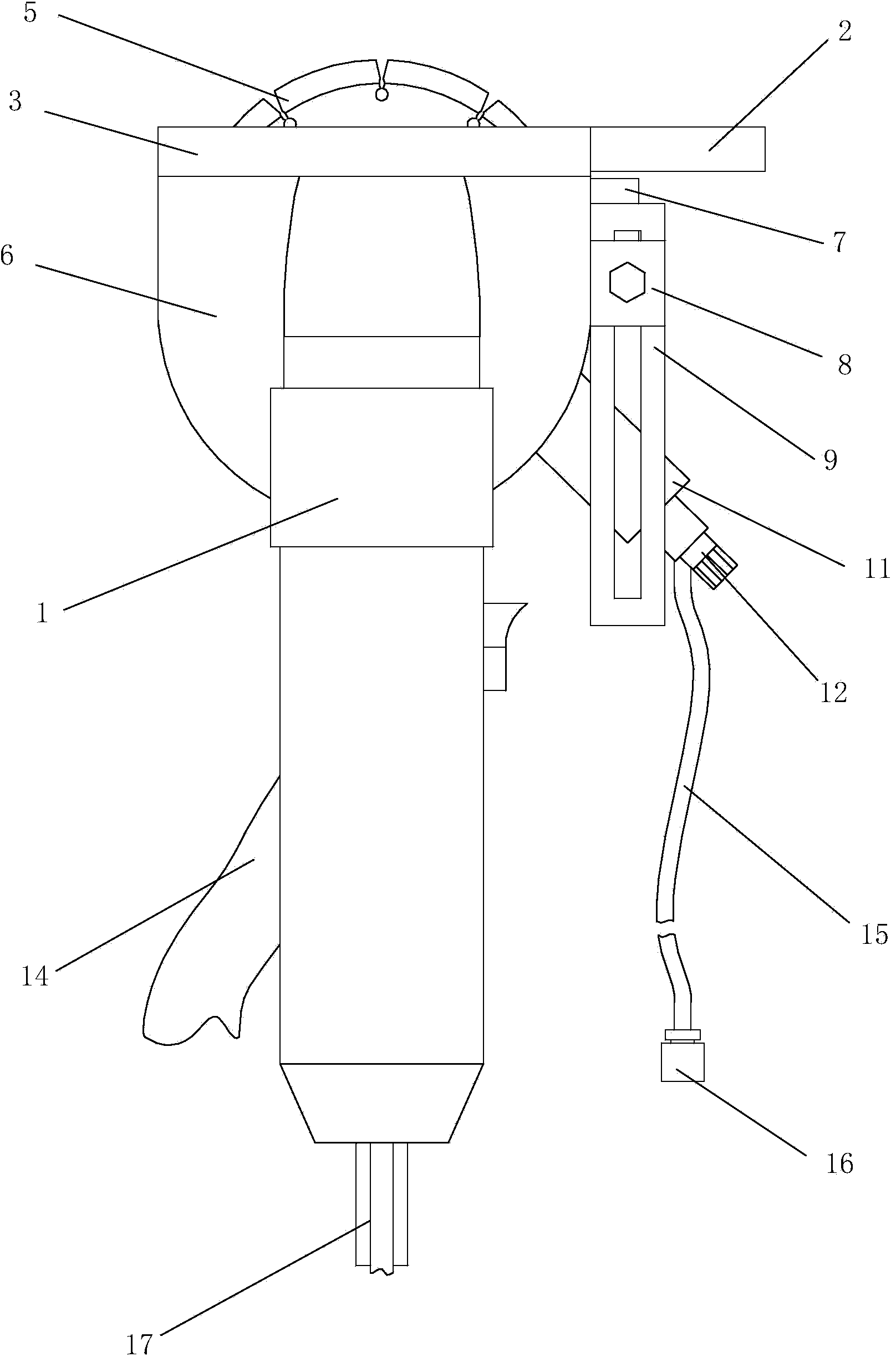

[0029] Such as Figure 1~4 As shown, the wall slotting machine of this embodiment includes an angle grinder 1, a waterproof cover 6, a waterproof baffle 3 and a nozzle 18; the main shaft of the angle grinder 1 is coaxially provided with at least one cutting piece 5; the waterproof cover The opening of 6 is located on one side of the front end of the angle grinder 1, the cutting piece 5 is arranged in the waterproof cover 6 and partly exposed outside the opening of the waterproof cover 6, the upper side of the waterproof cover 6 is provided with a water inlet 11; the waterproof baffle 3 is fixed It is outside the waterproof cover 6 and blocked at the front end of the angle grinder 1; the nozzle 18 is fixed in the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com