A kind of horizontal movement vibration rotary excavation and ballast filling machine between sleepers

A ballast dumping machine and traversing technology, applied in the directions of tracks, ballast layers, roads, etc., can solve the problems of sleeper damage, time-consuming and laborious, low work efficiency, etc., and achieve the effects of reliable performance, convenient operation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

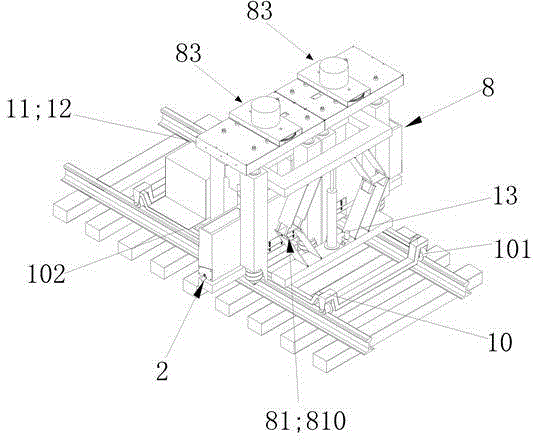

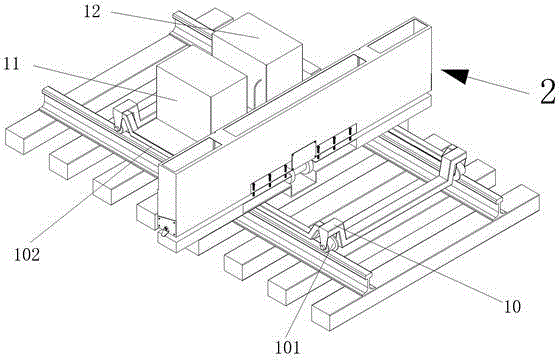

[0063] see figure 1 , figure 2 Shown, be the embodiment of the present invention, and this embodiment is made up of ballast collecting and discharging device 2, laterally moving and vibrating rotary dredging device 8, rail car 10, generator 11, hydraulic system box 12, camera assembly 13 and monitoring device composition. The rail car 10 is equipped with four casters 101 and two longitudinal beams 102. On the beam 102, the rail car 10 is towed by an engineering vehicle, the monitor is located in the cab of the tractor, the generator 11 provides power for the oil pump and the motor, and the hydraulic system box 12 is provided with a fuel tank, an oil pump, and various hydraulic control valves.

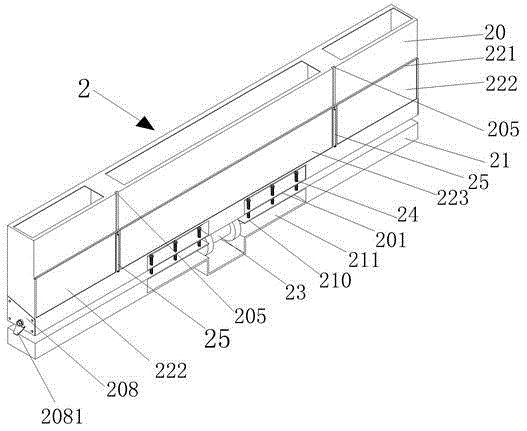

[0064] see Figure 2 to Figure 10 As shown, the ballast collection and discharge device 2 is composed of a box body 20, a lower beam 21, a linkage door 22, a first vibration motor 23, several elastic connection assemblies 24, two oil cylinders 25 and a sand discharge assembly 26, T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com