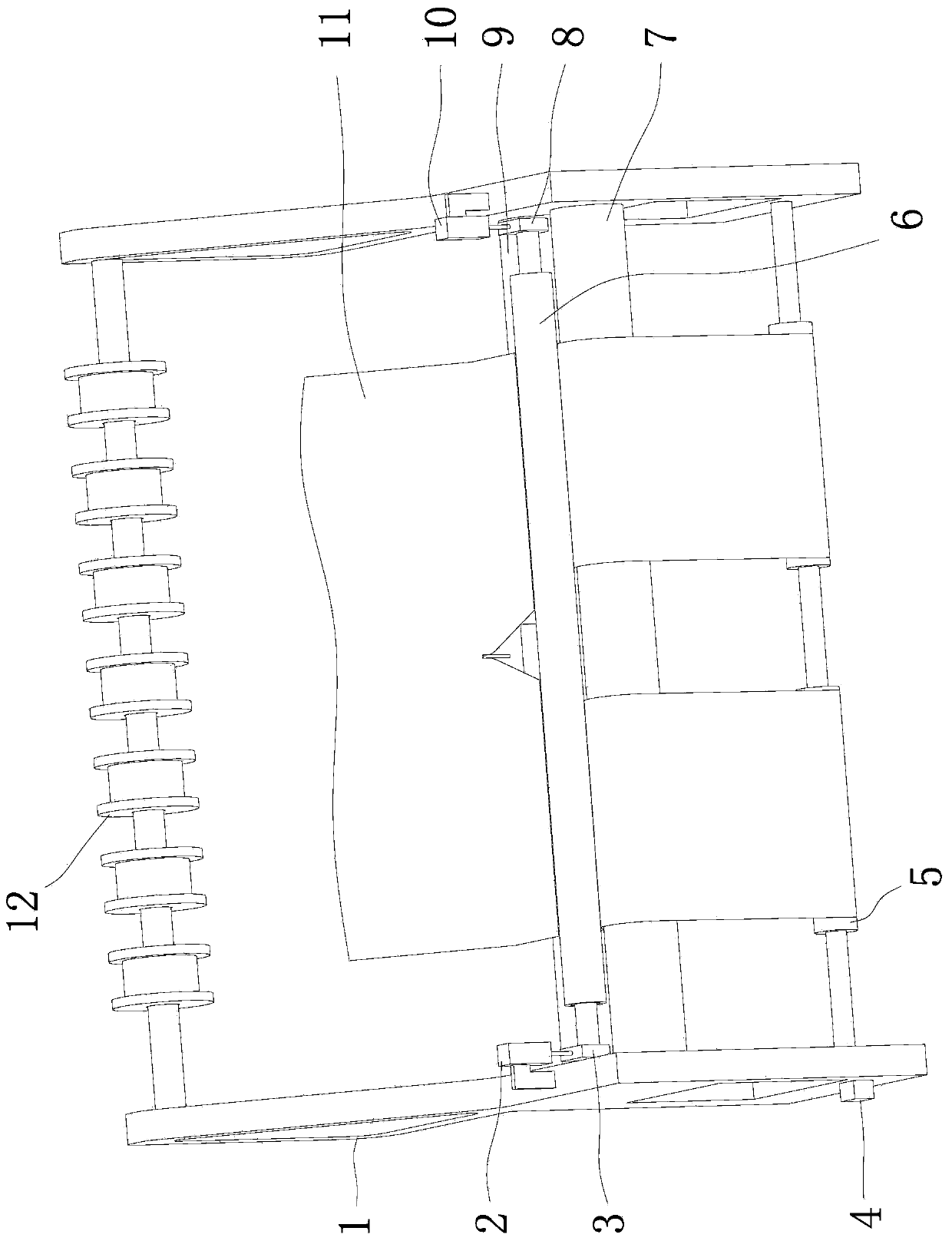

Warp knitting machine with improved structure

An improved structure and warp knitting machine technology, which is applied in warp knitting, textiles, papermaking, knitting, etc., can solve the problems that warp knitted fabrics cannot be divided, and achieve the effects of high cutting efficiency, stable work and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

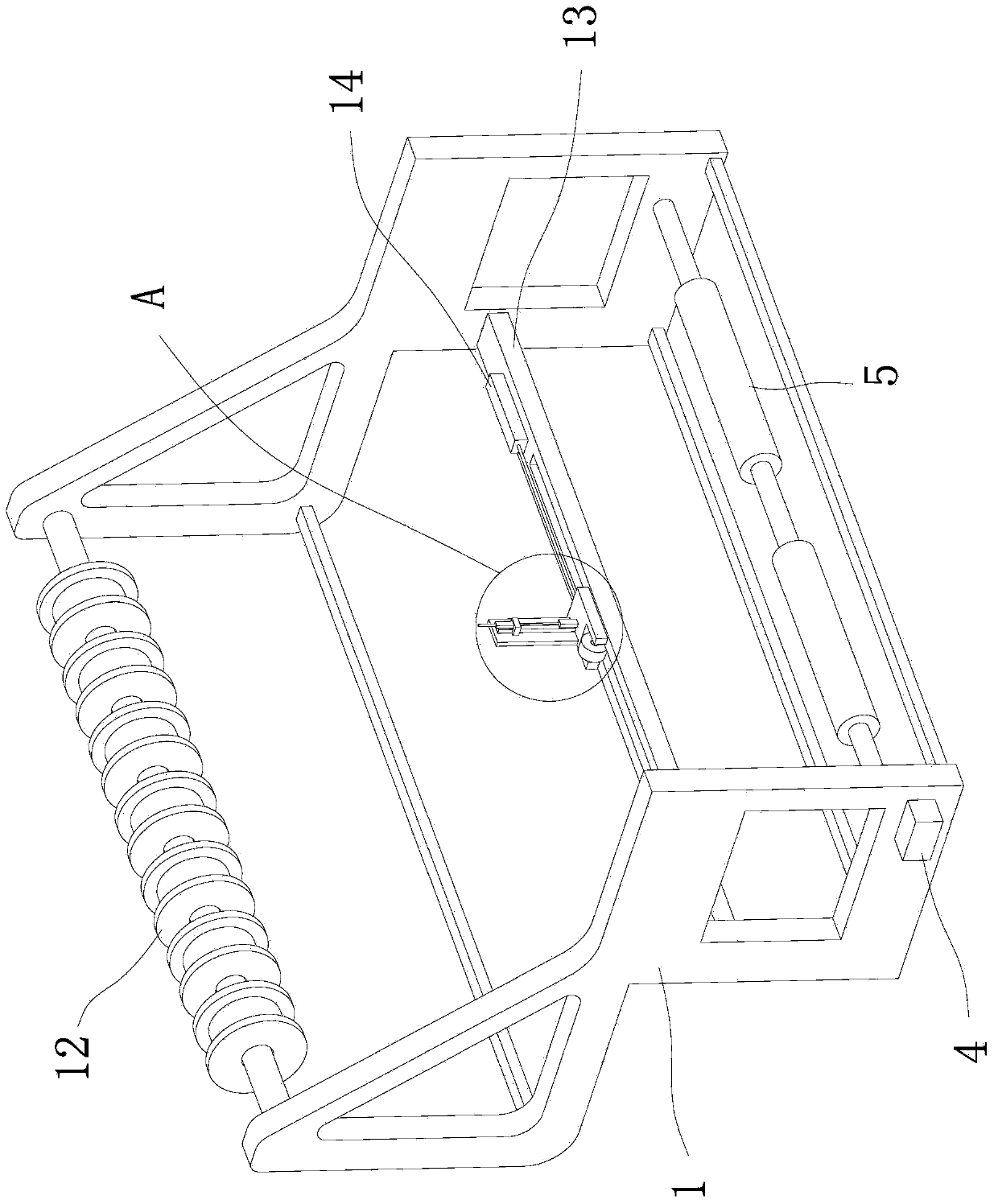

Examples

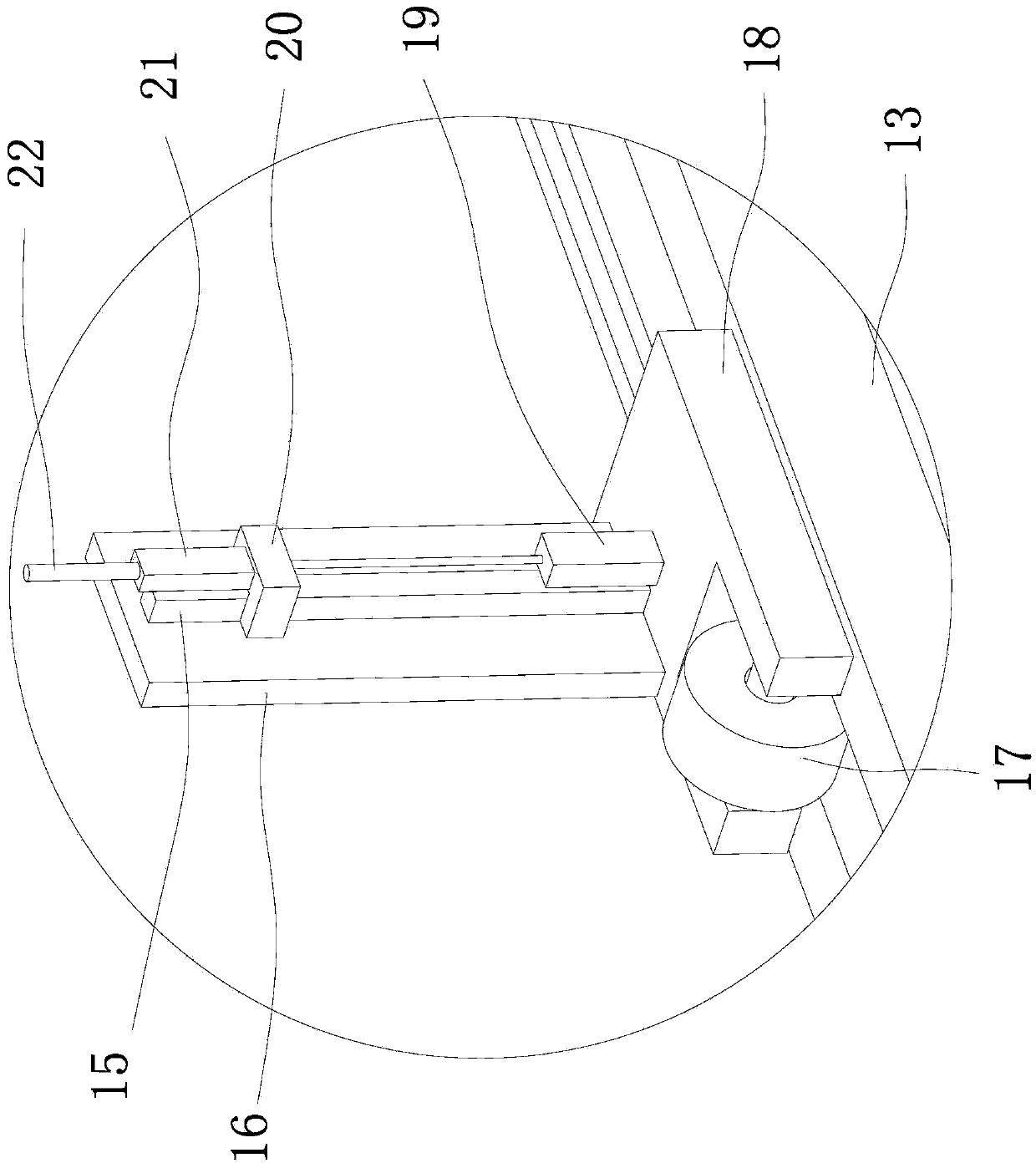

Embodiment 2

[0046] The content in the second embodiment is roughly the same as that in the first embodiment, except that the dividing device in the first embodiment includes a heating wire 22, and the upper end of the heating wire 22 is a working end that can be in contact with the warp knitted fabric 11. The lower end of the heating wire 22 links to each other with a lifting and positioning mechanism two that can drive it up and down and locate it; Between the bobbin 12 and the conveying shaft one 9, the lower end of the fixed plate 16 is connected with a moving mechanism that can drive it to move laterally. The guide rail 15 is fixed on the fixed plate 16 and arranged along the up and down direction. The slider 20 is arranged on the guide rail 15, the upper end of the insulating plate 21 is fixedly connected with the heating wire 22, the lower end of the insulating plate 21 is fixed on the slider 20, and the lower part of the slider 20 is also provided with a vertical cylinder 19 that ca...

Embodiment 3

[0048] The content in the third embodiment is roughly the same as that in the second embodiment, except that the rotating mechanism in the second embodiment includes a motor 32, a driving gear 31, a driven gear 30, an upper positioning bearing and a lower positioning bearing. The inner ring of the locating bearing is set and fixed on the uppermost end of the screw rod 33, the outer ring of the upper locating bearing is fixed on the frame 1, and the upper locating bearing is fixed on the frame 1 through the upper locating bearing seat 25; the inner ring of the lower locating bearing The snare is arranged at the lower end of the screw rod 33, the outer ring of the lower positioning bearing is fixed on the frame 1, and the lower positioning bearing is fixed on the frame 1 through the lower positioning bearing seat 24; the driven gear 30 is fixed at the lowermost end of the screw rod 33 , the motor 32 is fixed on the frame 1, the output shaft of the motor 32 is vertically upward, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com