Method of gravel grading design for high-speed rail subgrade

A technology of crushed stone gradation and high-speed railway foundation, which is applied in the field of crushed stone gradation design for high-speed railway foundation, and can solve problems such as poor skeleton and non-conformity to construction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The gradation of coarse aggregate and fine aggregate is: coarse aggregate 74.1%, fine aggregate 25.9%.

[0030] Among them, the amount of crushed stones of each particle size in the coarse aggregate is: 20.0% of crushed stones with a particle size of 4.75; 16.0% of crushed stones with a particle size of 9.5; 12.4% of crushed stones with a particle size of 13.2; 15.4%; 21.4% of 19-grain crushed stone; 14.8% of 26.5-grain crushed stone.

[0031]Among them, the crushed stone content of each particle size in the fine aggregate is: 0.075 particle size is 4.4%, 0.15 particle size is 10.8%, 0.3 particle size is 24.0%, 0.6 particle size is 14.5%, 1.18 particle size is 19.7% %, 2.36 particle size is 26.6%.

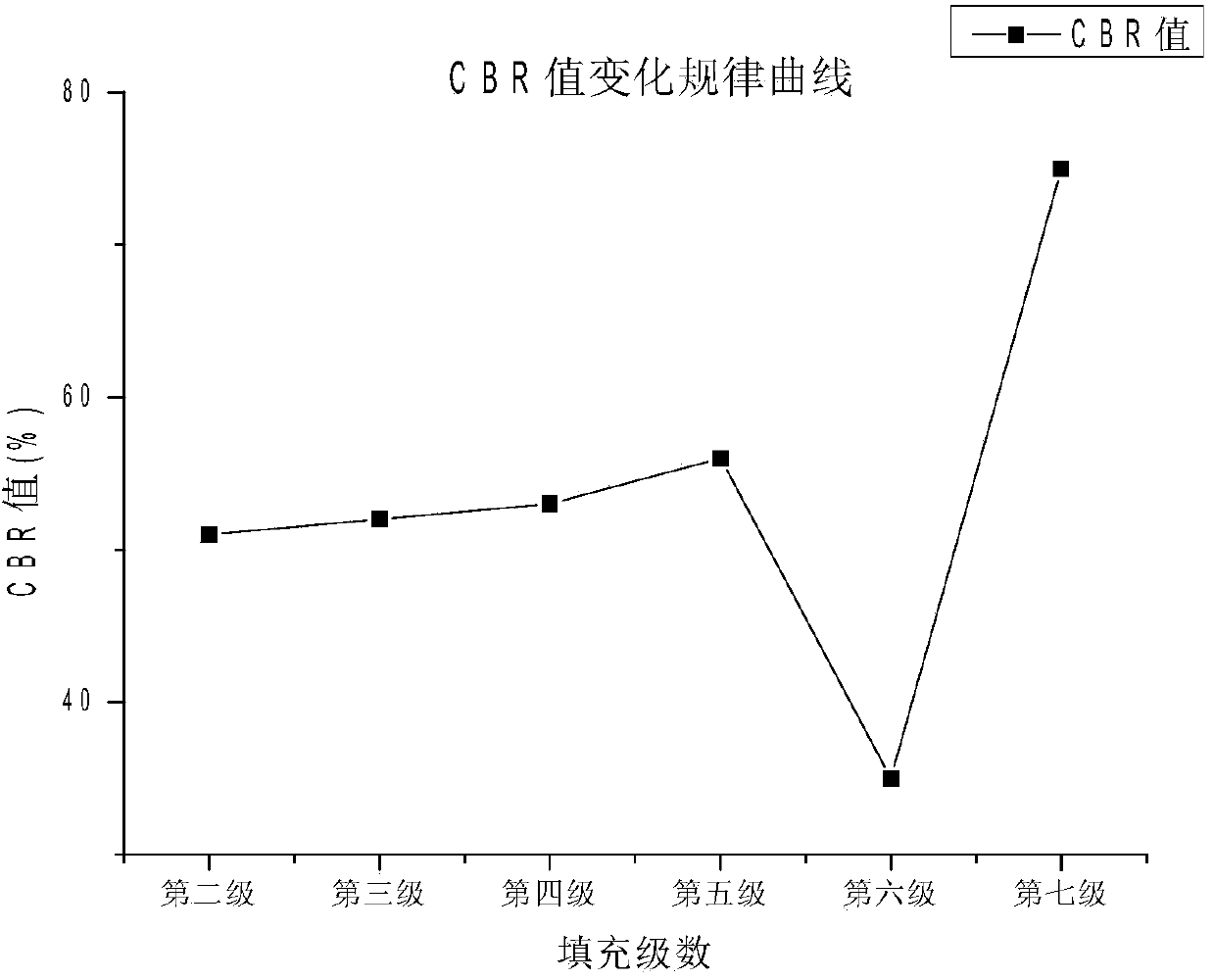

[0032] The graded crushed stone has a CBR value of 75 and a maximum dry density of 2.16g / cm 3 .

Embodiment 2

[0034] The gradation of coarse aggregate and fine aggregate is: coarse aggregate 74.1%, fine aggregate 25.9%.

[0035] Among them, the amount of crushed stones of each particle size in the coarse aggregate is: 15.0% of crushed stones with a particle size of 4.75; 18.0% of crushed stones with a particle size of 9.5; 14.4% of crushed stones with a particle size of 13.2; 16.4%; 19-grain crushed stone 21.4%; 26.5-grain crushed stone 14.8%.

[0036] Among them, the crushed stone content of each particle size in the fine aggregate is: 0.075 particle size is 4.4%, 0.15 particle size is 10.8%, 0.3 particle size is 24.0%, 0.6 particle size is 14.5%, 1.18 particle size is 19.7% %, 2.36 particle size is 26.6%.

[0037] The graded crushed stone has a CBR value of 73 and a maximum dry density of 2.13g / cm 3 .

Embodiment 3

[0039] The gradation of coarse aggregate and fine aggregate is: coarse aggregate 71%, fine aggregate 29%.

[0040] Among them, the amount of crushed stones of each particle size in the coarse aggregate is: 15.0% of crushed stones with a particle size of 4.75; 18.0% of crushed stones with a particle size of 9.5; 14.4% of crushed stones with a particle size of 13.2; 16.4%; 19-grain crushed stone 21.4%; 26.5-grain crushed stone 14.8%.

[0041] Among them, the crushed stone content of each particle size in the fine aggregate is: 0.075 particle size is 4.4%, 0.15 particle size is 10.8%, 0.3 particle size is 24.0%, 0.6 particle size is 14.5%, 1.18 particle size is 19.7% %, 2.36 particle size is 26.6%.

[0042] The graded crushed stone has a CBR value of 76 and a maximum dry density of 2.08g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com