Corner fitting for container, container and container-type movable house

A technology for containers and corner fittings, which is applied in the fields of prefabricated houses, container components and containers, which can solve the problems of welding and fixing effects, work efficiency and work environment pollution, and achieve the goal of improving work efficiency, reducing labor difficulty, and reducing industrial pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

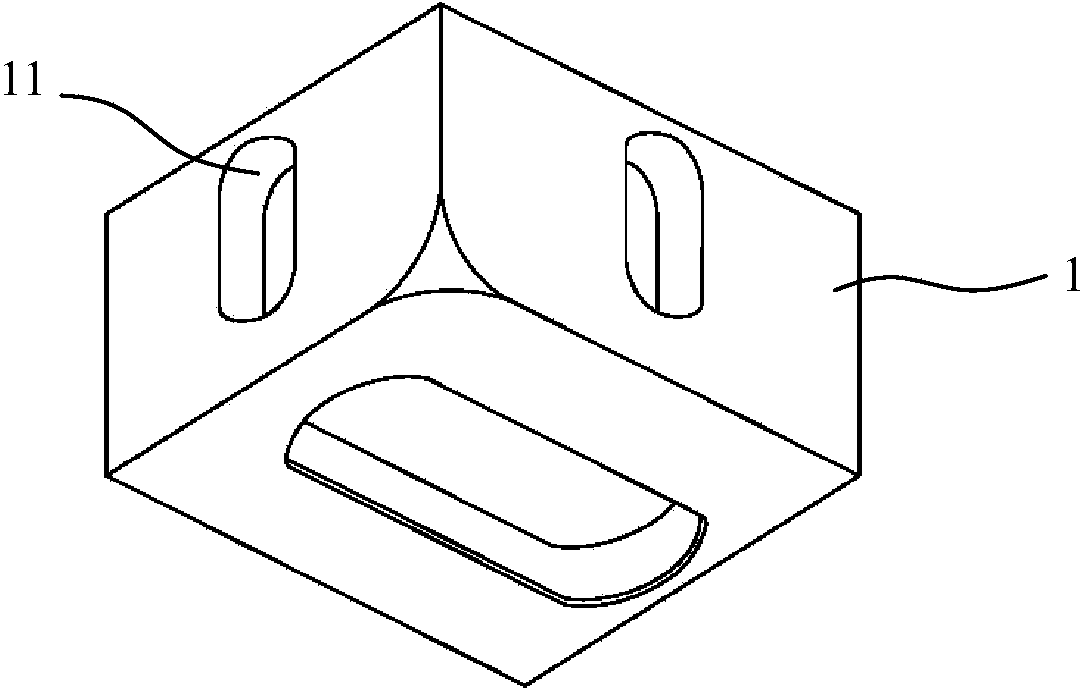

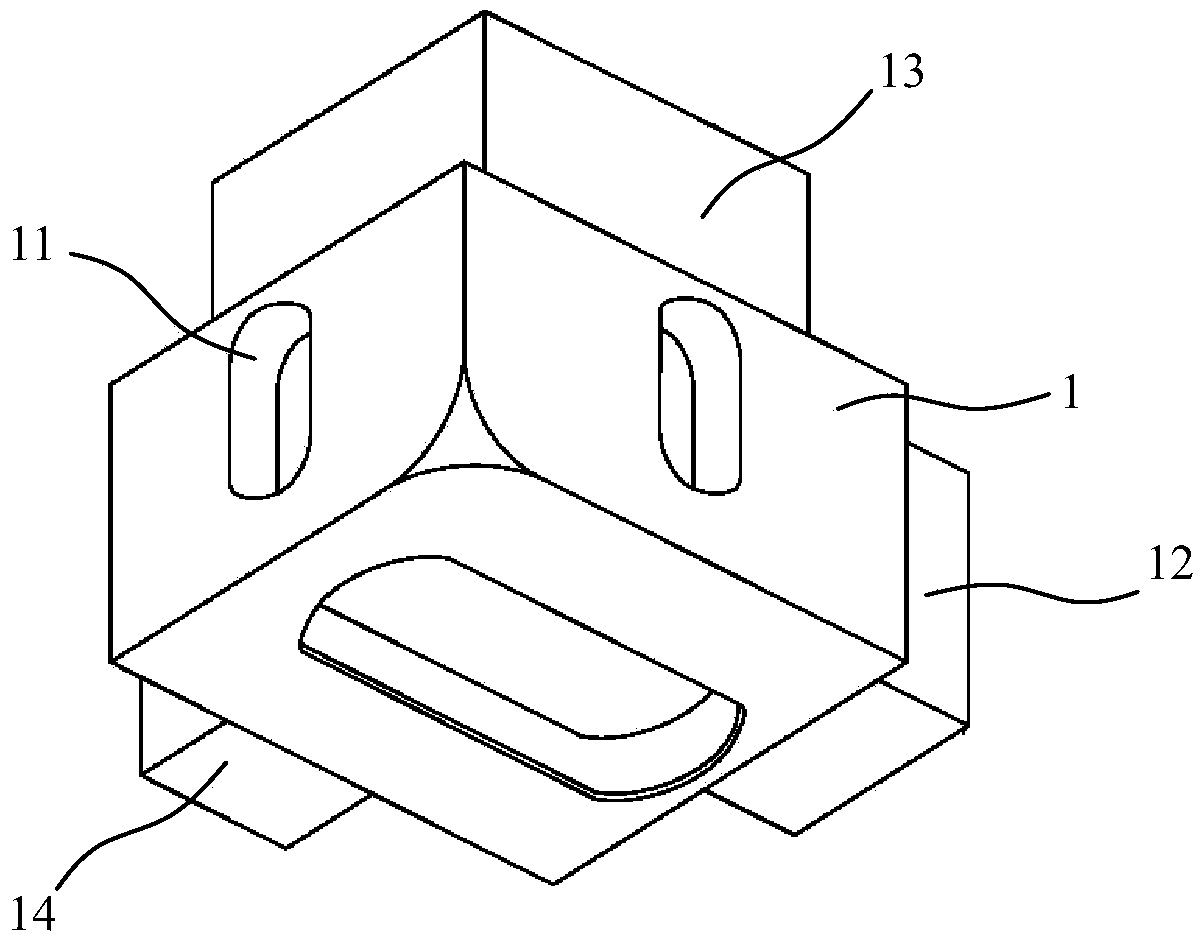

[0036] figure 2 It is a structural schematic diagram of a container corner fitting of the present invention.

[0037] See figure 2 , the container corner fitting provided by the present invention has a main body in a rectangular parallelepiped, and an installation through hole 11 is respectively arranged on its three outer end faces towards the outside of the container, and its other three end faces can be connected with the container side beam 3, the upright column 2 and the end face respectively. The beam 4 is fixedly connected, and at least one of the three end faces connected to the container side beam 3, the column 2 and the end beam 4 is provided with a connecting boss. Preferably, the container side beam 3, the column 2 Connecting bosses 12 , 13 and 14 are respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com