Ship anti-rolling device

An anti-rolling device and ship technology, which is applied in the field of ships, can solve the problems of high manufacturing cost and maintenance cost, high cost of anti-rolling, large tonnage of ships, etc., and achieve the effects of improving safety, reducing roll, and increasing deadweight tonnage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

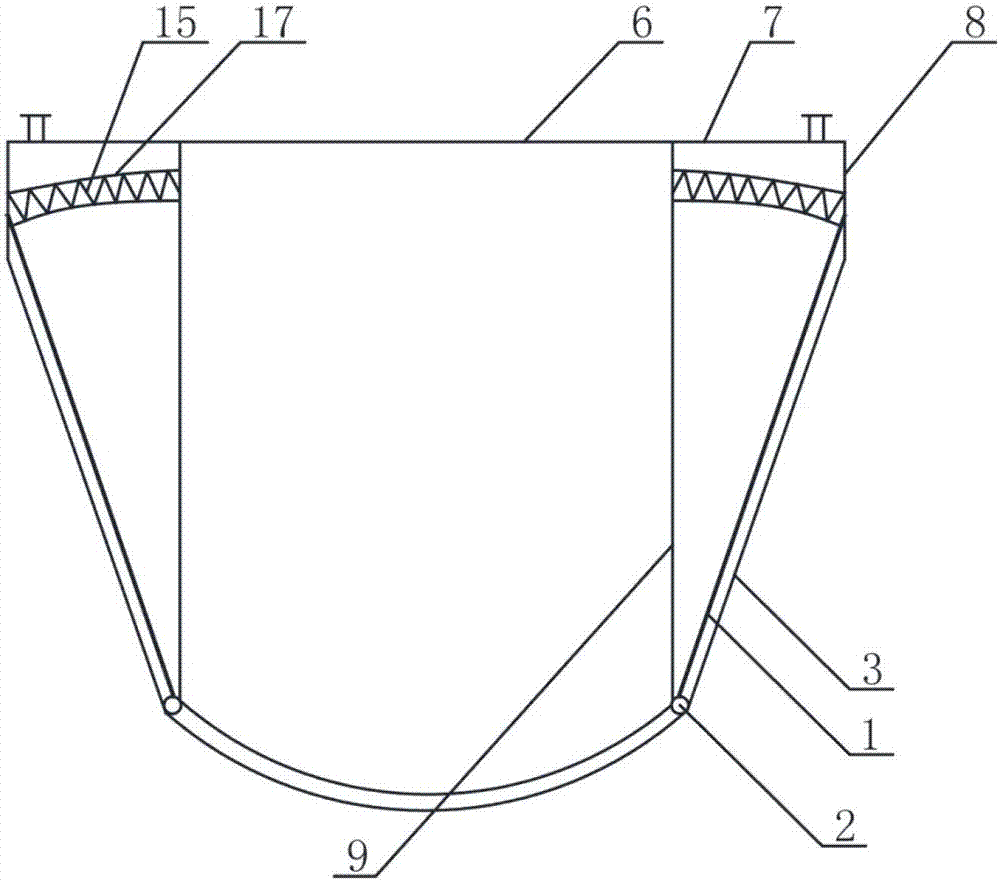

[0058] like figure 1 , Figure 8 , Figure 10 , Figure 11 As shown, in the ship anti-rolling device provided by Embodiment 1 of the present invention, the ship anti-rolling device is provided with one or more buffer energy-absorbing mechanisms on both sides of the hull (14). The buffer energy-absorbing mechanism includes a side wall 1 and an elastic member 15. One end (the lower end in the figure) of the side wall 1 is connected to the bilge of the ship through a movable joint 2, and the other end (the upper end in the figure) passes through the The elastic member 15 is connected to the side shell 9 . The side wall 1 rotates around the movable joint 2, one end (the inner end in the figure) of the elastic member 15 is fixedly connected with the side outer plate 9, and the other end (the outer end in the figure) is connected with the side wall 1 connection. Preferably, the elastic member 15 is a helical compression spring.

[0059] The anti-rolling device can effectively ...

Embodiment 2

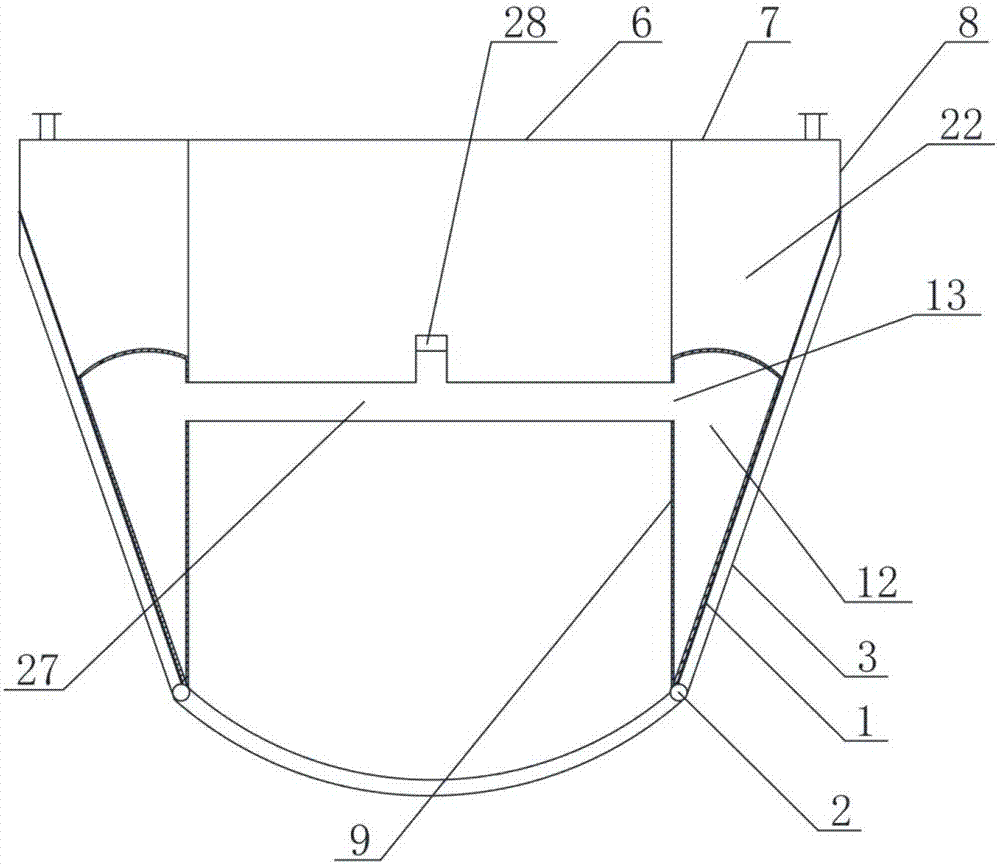

[0067] like figure 2 , Figure 5 and Figure 11 As shown, in the ship anti-rolling device provided by the second embodiment of the present invention, the ship anti-rolling device is provided with one or more buffer energy-absorbing mechanisms on both sides of the hull (14). The buffer energy-absorbing mechanism includes a side wall 1 and an air bag 12. One end (lower end in the figure) of the side wall 1 is connected to the bilge of the ship through a movable joint 2, and the side wall 1 and the side shell 9 Said airbags 12 are arranged therebetween.

[0068] The anti-rolling device can effectively buffer, absorb, and transform the lateral force of waves on one side of the hull 14, reduce the roll of the ship, and keep the ship sailing smoothly.

[0069] The opposite air bag 12 inner wall of hull (14) both sides is provided with opening 13, and the described opening 13 of two described air bags 12 is communicated by connecting pipe 27, has realized the communication of opp...

Embodiment 3

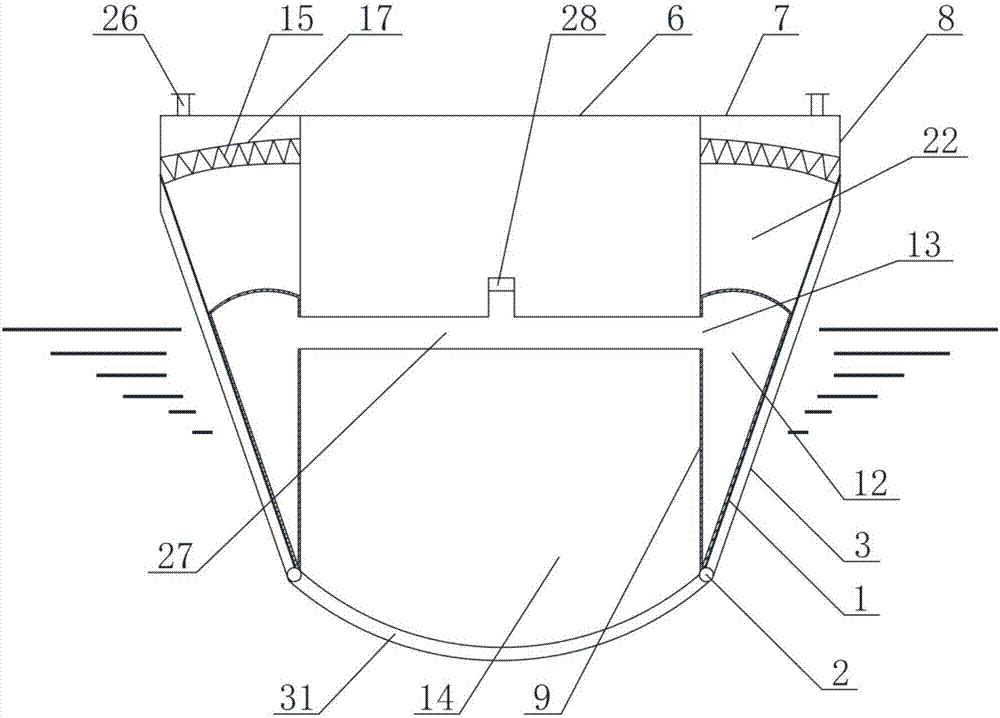

[0075] like Figure 3-12 As shown, in the ship anti-rolling device provided by the third embodiment of the present invention, the ship anti-rolling device is provided with one or more buffer energy-absorbing mechanisms on both sides of the hull (14). The buffer energy-absorbing mechanism includes a side wall 1, an elastic component 15 and an air bag 12. One end of the side wall 1 is connected to the bilge of the ship through a movable joint 2, and the other end is connected to the side shell 9 through the elastic component 15. Connection; the airbag 12 is arranged between the side wall 1 and the side shell 9 .

[0076] The anti-rolling device can effectively buffer, absorb, and convert the lateral force of waves on one side of the hull 14 through the elastic component 15 and the airbag 12, so as to reduce the roll of the ship and keep the ship sailing smoothly.

[0077] A deck extension 7 is provided above the buffer energy-absorbing mechanism, one end (inner end in the figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com