Safety one-way perspective glass as well as production method and application thereof

A one-way perspective glass, safe technology, applied in chemical instruments and methods, glass/slag layered products, coatings, etc., can solve the problems of easy to be scratched, scattered, poor safety, etc., to achieve better mirror effect, Improve durability, good decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

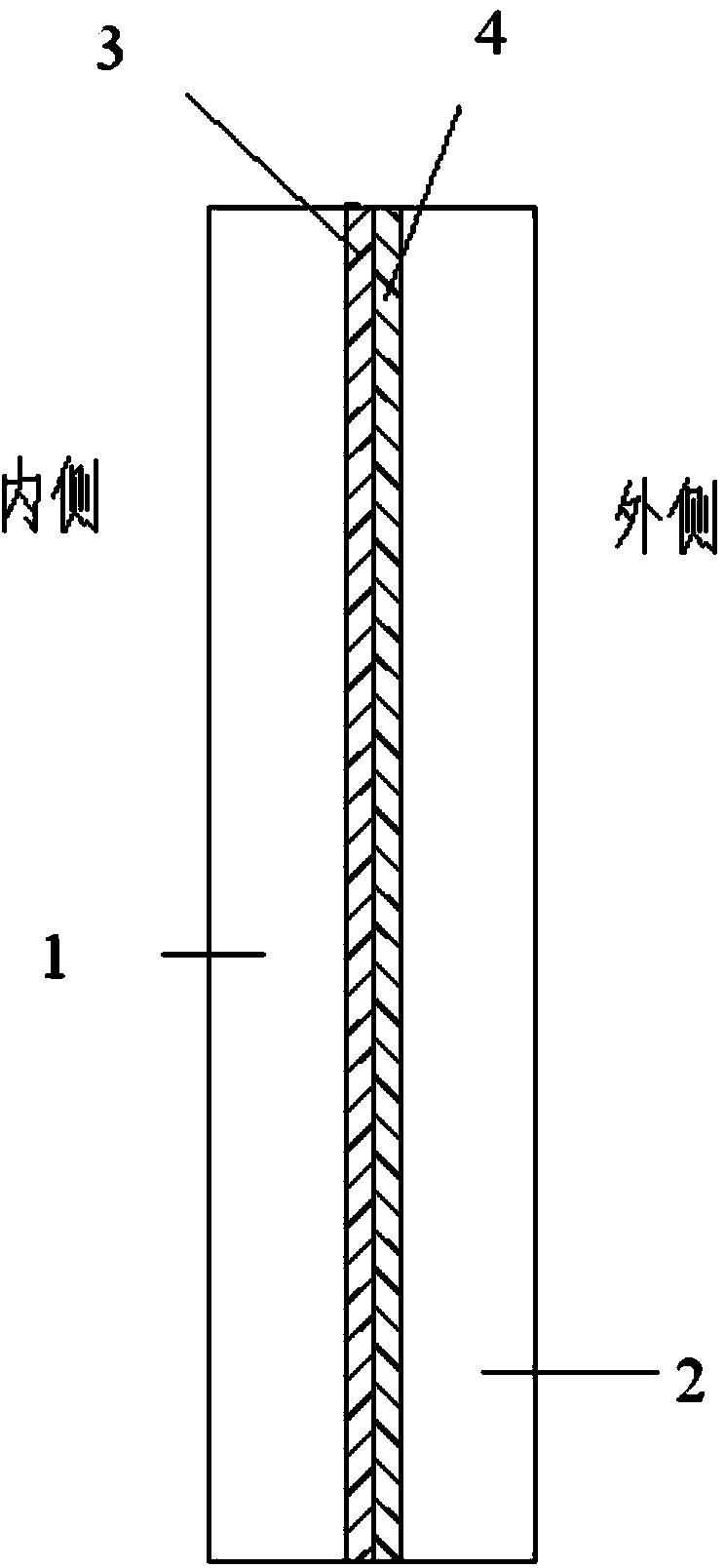

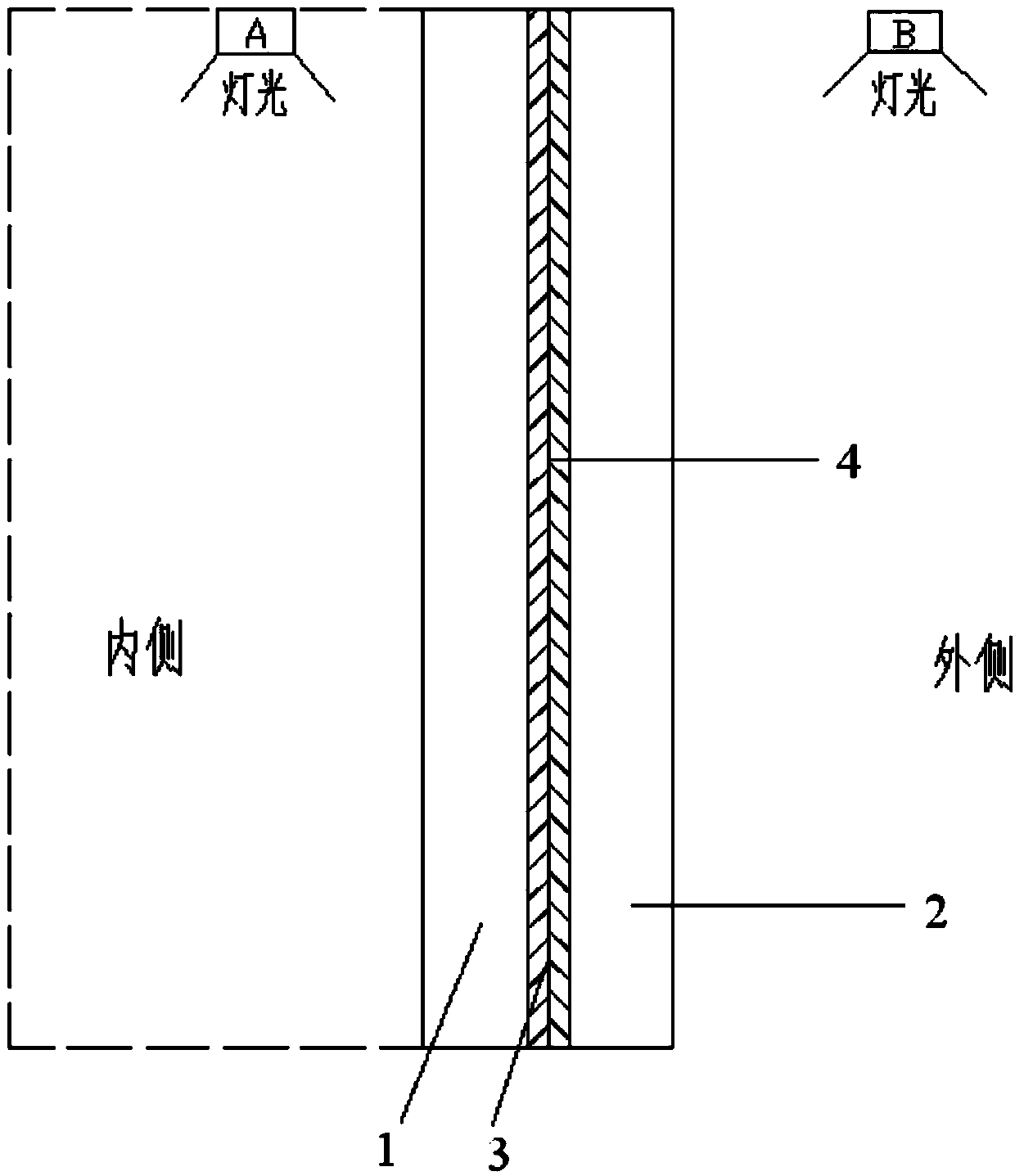

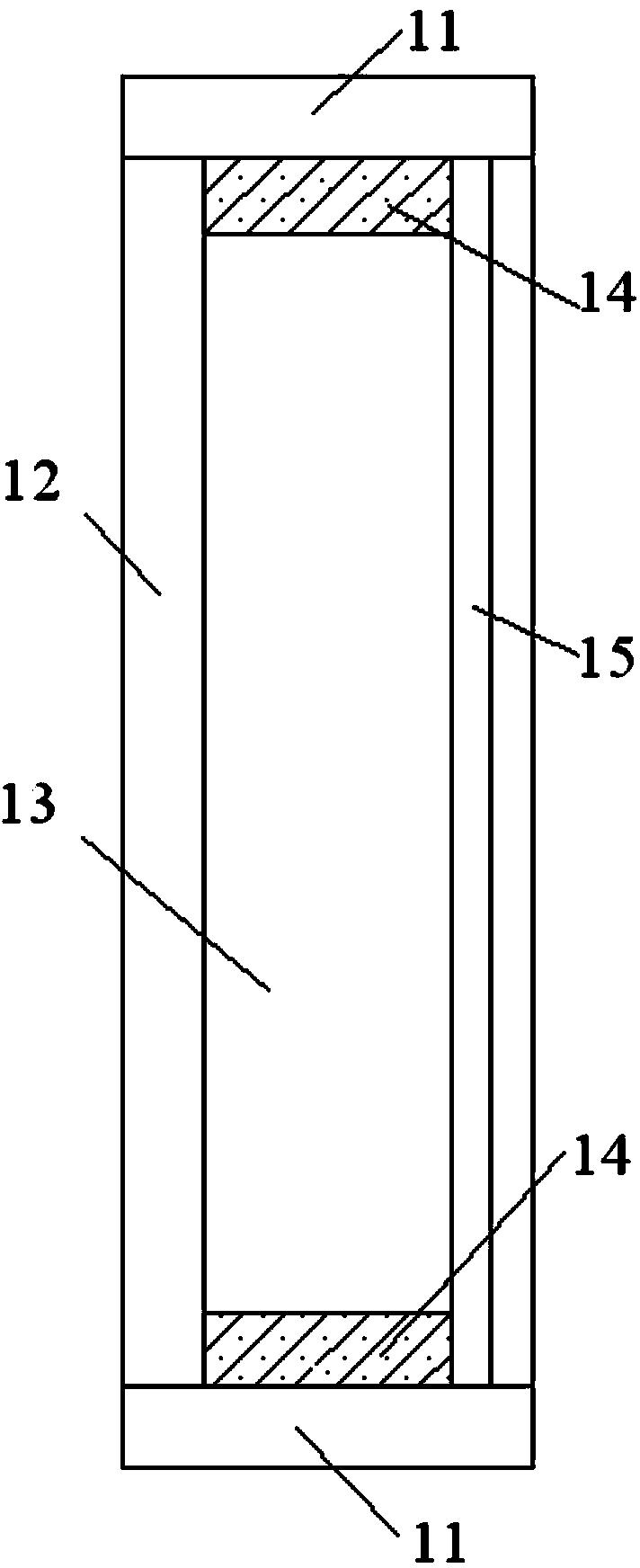

[0021] refer to figure 1 , the safety one-way see-through glass of the present invention is synthesized under high pressure by sandwiching a transparent film 3 between two sheets of glass 1 and 2, wherein the glass 2 is a coated beam splitter, the glass 1 is ordinary glass, and the beam splitting layer 4 of the coated beam splitter is arranged on Between two pieces of glass 1, 2; the glass 1, 2 can be flat or curved. The coated beam splitter 2 is preferably a magnetron sputtered coated beam splitter. The transparent film is preferably a PVB film. The sunlight reflectance of the light-splitting film layer is between 40%-95%, and the light-splitting ratio is T:R=1:9-5:5. The key point of the present invention is that the light-splitting film layer 4 is in the middle of the glass 1, 2, and the two layers of glass are synthesized by a lamination method, the film layer is protected, and the whole constitutes a safety glass. Both sides of the safety one-way see-through glass of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com