An electrolytic wire turning equipment with narrow and deep grooves on a rotary body

A deep groove and rotary body technology, applied in the field of new special processing equipment, can solve the problems of large electrode wire consumption, complex equipment structure, high processing cost, etc., and achieve the effects of saving electrode wires, good surface quality, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention are described in detail below.

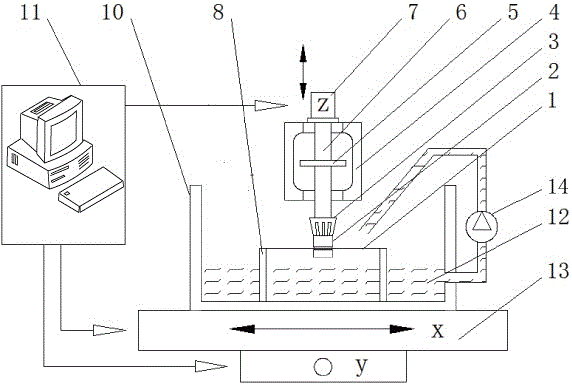

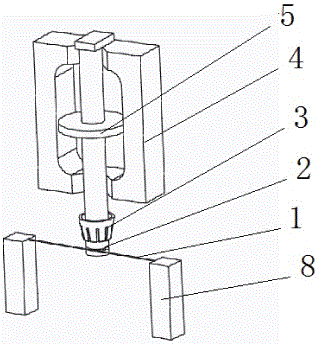

[0017] refer to figure 1 , figure 2 As shown in the figure, the overall structure and partial three-dimensional structure of an electrolytic wire turning equipment with narrow and deep grooves on the rotary body of the present invention are shown in the figure. Referring to the figure, the electrolytic wire turning equipment includes a base (not shown in the figure), an electrolyte tank 10 installed on the base, two electrode columns 8 fixedly installed in the electrolyte tank 10, and a suspension installation The wire electrode 1 between the two electrode columns 8, the shaft base 4 installed on the base, the main shaft 6 installed on the shaft base 4, the servo installed on the shaft base 4 to drive the main shaft 6 to rotate The motor 7, the collet 3 fixed on the front end of the main shaft 6 for clamping the workpiece 2, the wire electrode 1, the electrolyte tank 10 and the electrode column 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com