Anti-blockage angle conveying belt

A technology of conveyor belts and conveyor belts, which is applied in the field of automation, can solve problems such as stuck conveyed materials and material accumulation, and achieve the effect of reducing the accumulation of goods and reducing machine idling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

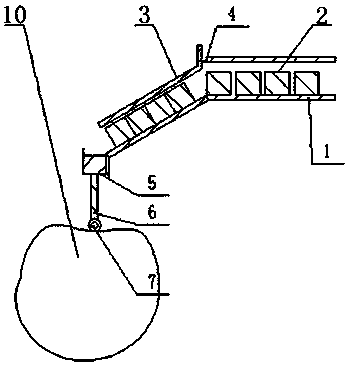

[0011] Such as figure 1 As shown, an anti-blocking type corner conveyor belt includes a transverse conveyor belt channel 1, an oblique conveyor belt channel 3 is connected below the end of the lateral conveyor belt channel 1, and a stall protrusion is provided above the oblique conveyor belt channel 3. A square peep hole 4 is arranged between the platform protrusion and the transverse conveyor belt channel.

[0012] Conveyor belts are provided only below the transverse conveyor belt channel and the oblique conveyor belt channel.

[0013] A lifting tray is arranged below the inclined conveyor belt channel.

[0014] After adopting the above scheme, the present invention has the following beneficial effects compared with the prior art: this scheme has the function of eliminating stuck objects, and when there are stuck objects, they can be found in time through the peephole a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com