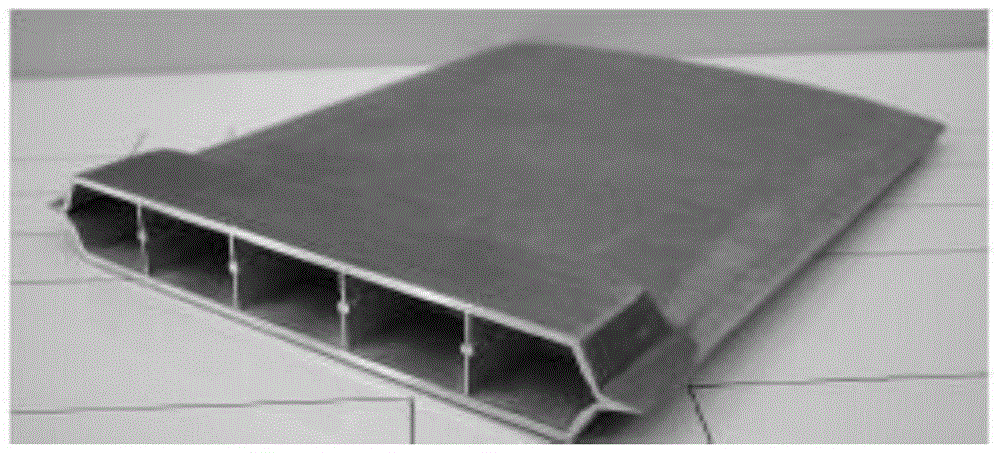

A Mesh Coordinated Forming Method for Superplastic Forming/Diffusion Bonding Four-Layer Structures

A technology of diffusion joining and superplastic forming, applied in the field of thin-walled structure forming technology, can solve the problem of inconsistent mesh forming degree and achieve the effect of coordinated forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

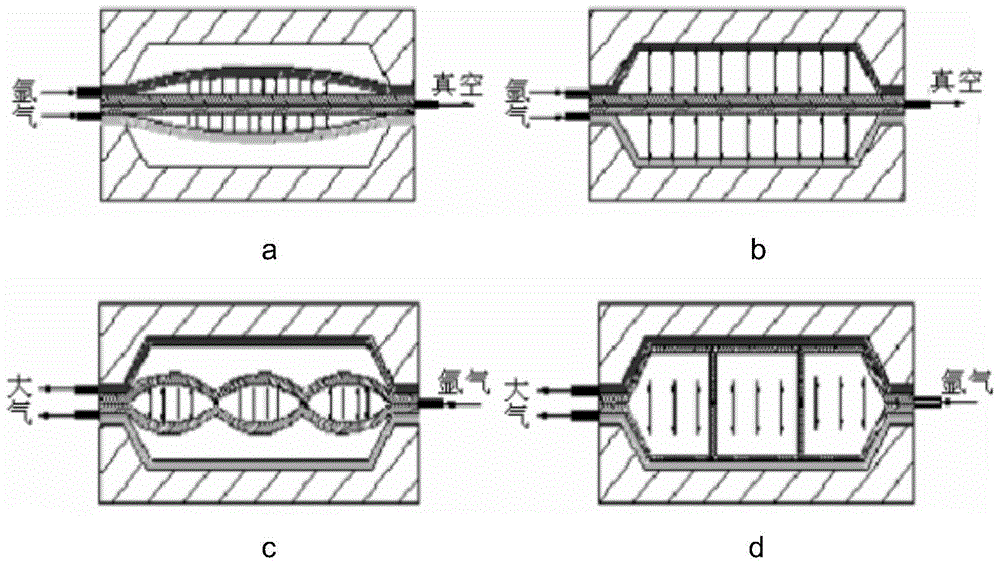

Method used

Image

Examples

Embodiment 1

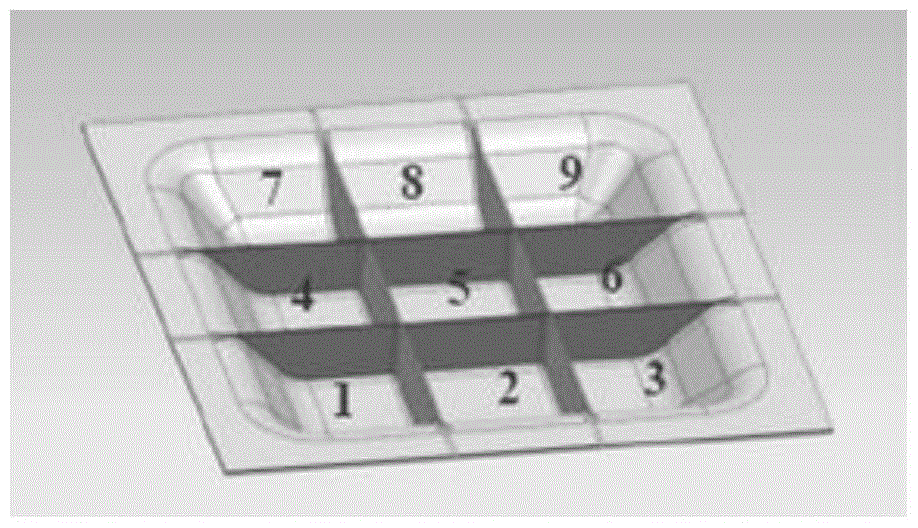

[0062] Taking the superplastic forming / diffusion connection of a square four-layer thin-walled structural part with nine meshes as an example, mesh coordinated forming is performed. The specific process is as follows, such as Figure 4 Shown:

[0063] Step 1. Set the position of the main intake air path

[0064] Set the main intake air path at the edge center of the No. 2 grid in the middle of one side of the part;

[0065] Step 2. Sort all the grids according to the distance from the main gas path

[0066] According to the distance from the main intake air path, the grids are sorted from No. 1 to No. 9. The number of grids passing through from the main intake air path to the target grid is n, and n is a natural number, that is

[0067] The number of grids passing through from the main intake gas path to grid No. 2 is n=0,

[0068] The number of grids passing through from the main intake gas path to grids 1, 3 and 5 n=1,

[0069] The number of grids passing through from t...

Embodiment 2

[0080] Taking the superplastic forming / diffusion connection of a rectangular four-layer thin-walled structural part with 24 meshes as an example, mesh coordinated forming is performed. The specific process is as follows, such as Figure 5 Shown:

[0081] Step 1. Set the position of the main intake air path

[0082] Set the main intake air path at the edge center of the No. 3 grid in the middle of the longer side of the part;

[0083] Step 2. Sort all the grids according to the distance from the main gas path

[0084] According to the distance from the main intake air path, the grids are sorted from No. 1 to No. 24. The number of grids passing through from the main intake air path to the target grid is n, and n is a natural number, that is

[0085] The number of grids passing through from the main intake gas path to grid No. 3 n=0,

[0086] The number of grids passing through from the main intake gas path to grids 2, 4 and 9 is n=1,

[0087] The grid number n=2 is the numb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com