Pipeline stain remover

A pipeline, the eleventh technology, applied in the field of pipeline eliminator, can solve the problems of leaking gas, unstable running speed, waste of gas source, etc., and achieve the effect of prolonging the service life, uniform running speed, and remarkable comprehensive benefit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention will be described in detail in order of claims with reference to the drawings and examples.

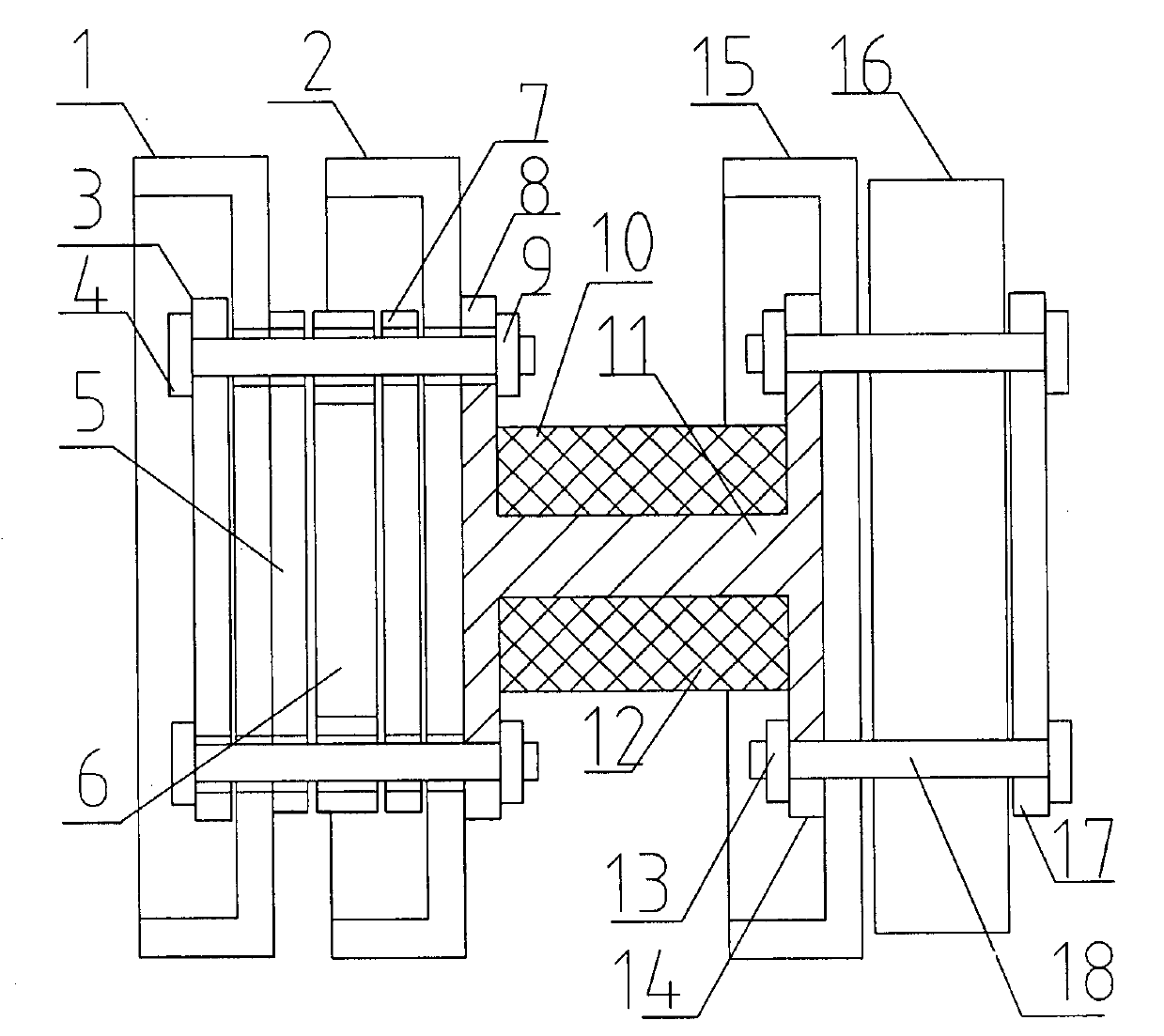

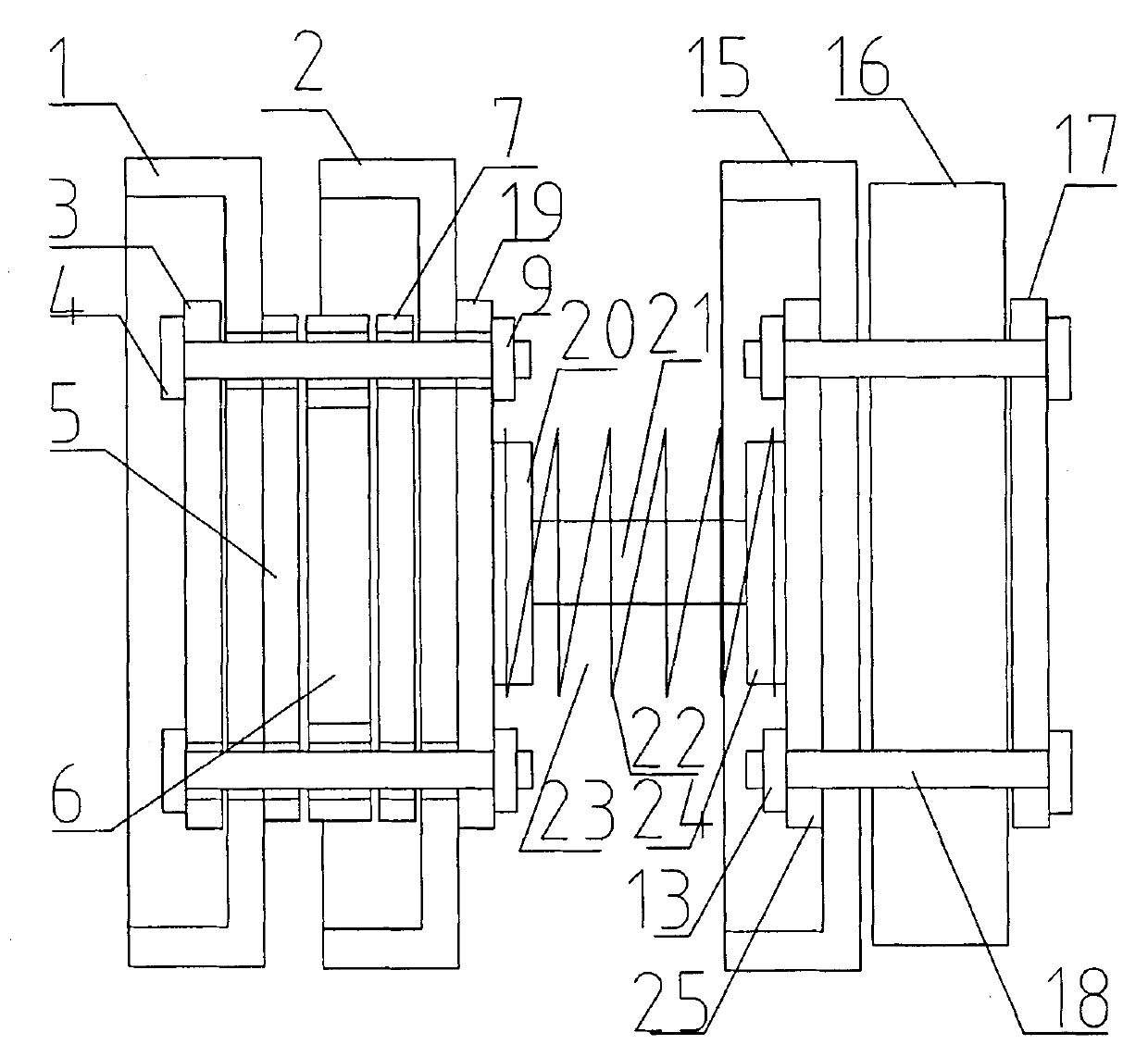

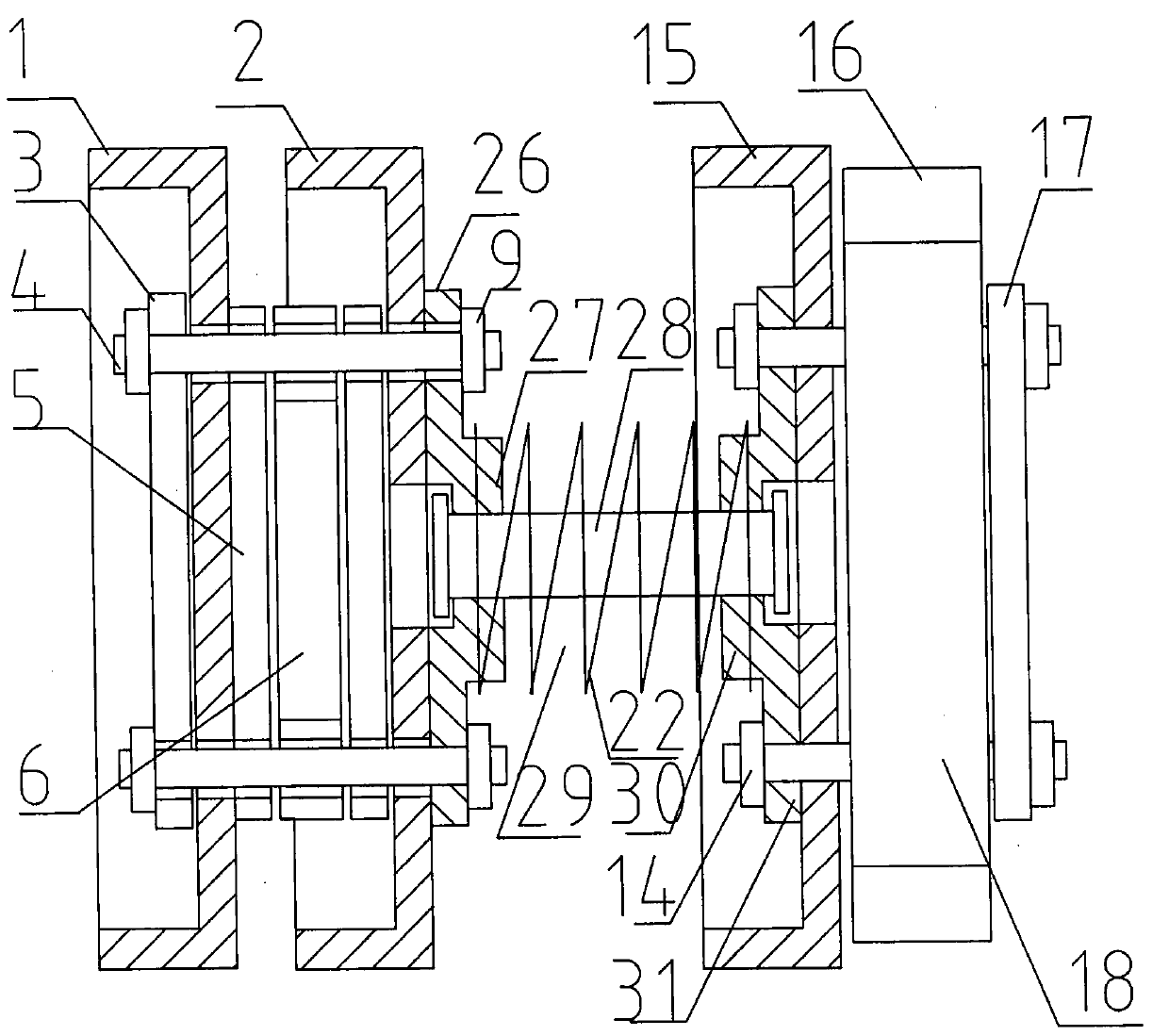

[0028] figure 1 It is a schematic front view of a pipe eliminator with a rubber sleeve on the outside of the first elastic shaft of the present invention, a pipe eliminator comprising a first sealing cup 1, a second sealing cup 2, and a third sealing cup 15 , the descaling wheel 16 and the first elastic shaft 10, one end of the first connecting rod 11 of the first elastic shaft 10 is connected to the first flange 8, the other end is connected to the second flange 14, and the first flange 8 is connected to the second seal The cup 2, the second flange 14 is connected to the third sealing cup 15, and the rubber sleeve 12 is installed on the outside of the first connecting rod 11. The rubber sheath 12 can be made of any elastic material, and the function of the rubber sheath 12 is to assist the first connecting rod 11 to return to the previous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com