An automatic medicine bottle washing and drying machine

A technology for dryers and medicine bottles, which is applied in the direction of dryers, drying gas arrangement, drying, etc., can solve the problems of drug light inspection quality and labeling quality, drug dust pollution, etc., and achieve convenient and simplified cleaning and drying process Production process, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

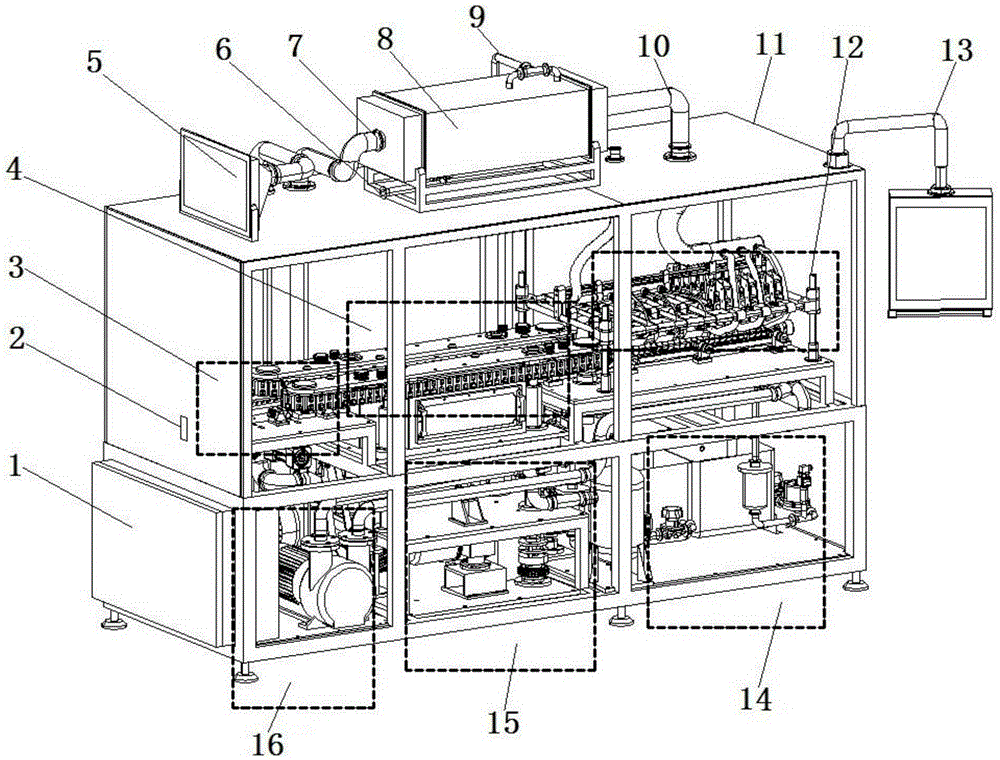

[0014] see figure 1 , in the embodiment of the present invention, an automatic medicine bottle washing and drying machine, the body is supported by a general equipment bracket 11, an electric control box 1 is provided under the left side of the body, and a suspended industrial control panel operation box 13 is provided on the right side of the top of the body, which can Touch screen operation is performed on this product, there is a coarse-effect filter 5 on the left side of the top, and a double-pipe interlayer cooler 8 is arranged on the right side of the coarse-effect filter 5; the left side of the double-pipe sandwich cooler 8 A heat exchanger water inlet 9 and a heat exchanger air inlet 10 are provided, a heat exchange water outlet 6 is provided on the top, a heat exchanger air outlet 7 is provided on the right side, and a small and medium filter is also provided at the heat exchanger air outlet 7 filter and high-efficiency filter; there is a bottle inlet 2 on the upper l...

Embodiment 2

[0017] see figure 2 , in the embodiment of the present invention, an automatic medicine bottle cleaning and drying machine, the bottle feeding method is changed to enter from the vertical direction of the screw rod through the wide web, and the wide mesh belt inlet can be entered by a single-track mesh belt or a multi-track mesh belt. Entering, to meet the purpose of different track numbers of the previous equipment, to realize automatic bottle feeding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com