Automatic hamburger making machine

A production machine and automatic technology, applied in filling baked goods, baked goods, baking, etc., can solve the problems of small number of hamburgers, low degree of automation, inability to use large-scale factory production of hamburgers, etc., to save time and standardize. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0027] The automatic hamburger making machine of the present invention can realize the steps of toasting bread, adding meat, adding sauce, and adding lettuce.

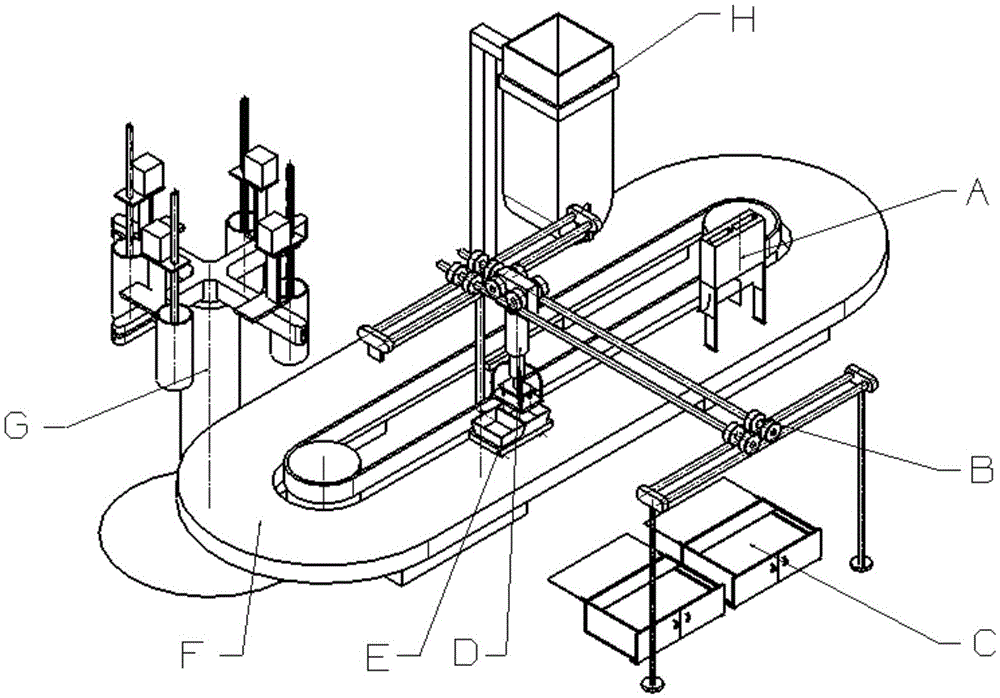

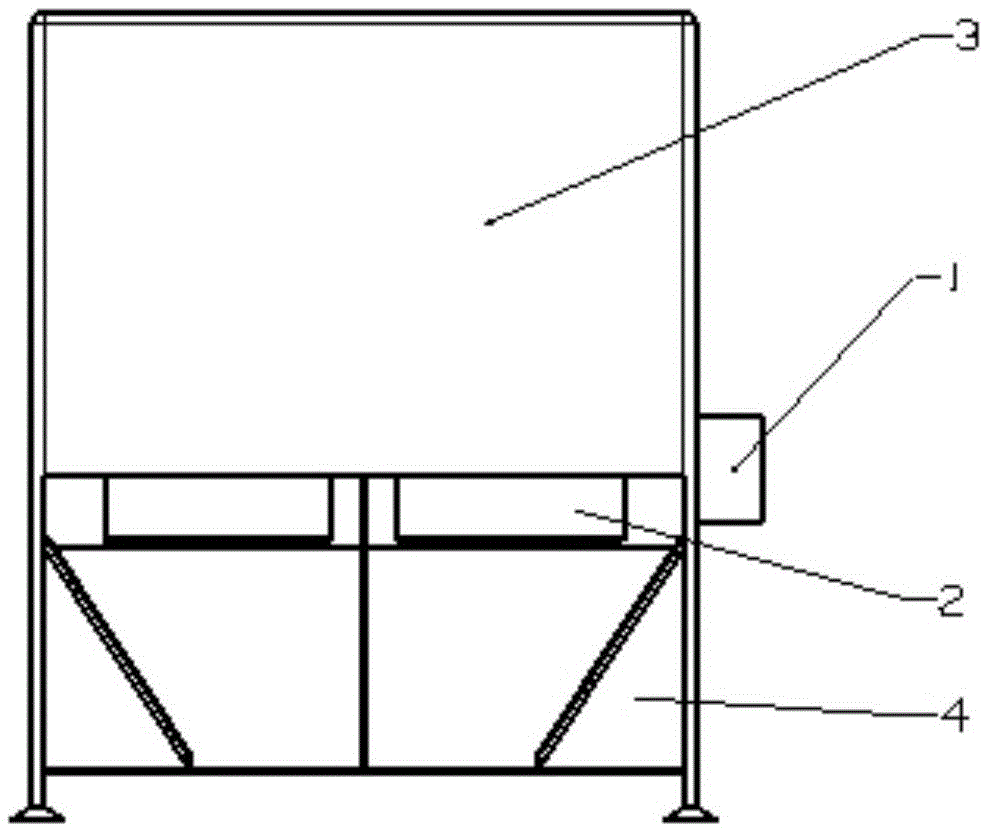

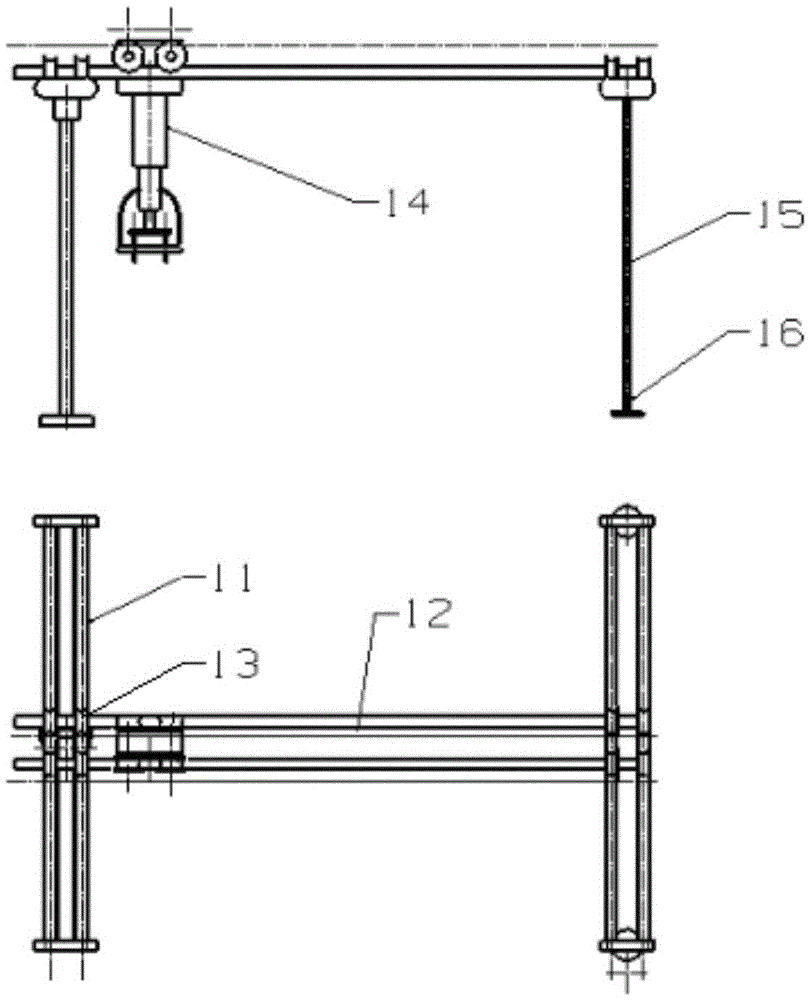

[0028] refer to figure 1 , the overall equipment of the automatic hamburger making machine of the present invention, including: A: oven mechanism, B: crane system, C: locker, D: manipulator, E: pallet trolley, F: rotating assembly line, G: cross rotating sauce Gun mechanism, H: automatic vegetable feeding mechanism and control system. The crane system includes beams and vertical beams arranged above the rotating assembly line, and the lockers are placed under the beams on one side of the crane system and close to the rotating assembly line. The rotating assembly line has a workbench, a main motor, a rotating shaft, a transmission belt, and a robot The rollers move on the vertical beam of the crane system, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com