Tobacco field management method for improving quality of upper tobacco leaves

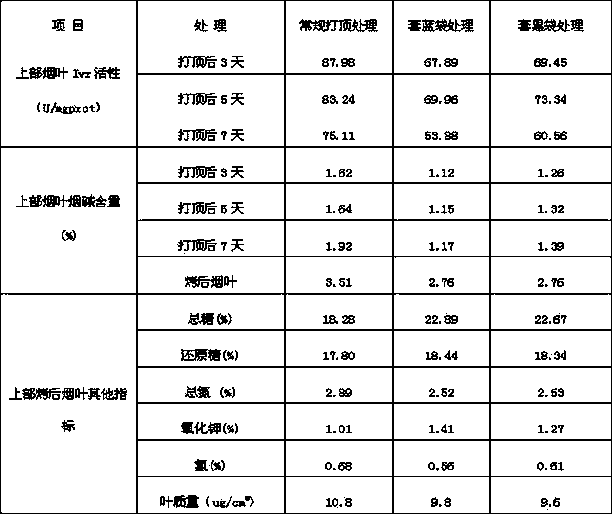

A technology for flue-cured tobacco and tobacco leaves, which is applied in the field of flue-cured tobacco management, can solve the problems of low reducing sugar content and sugar-to-base ratio, uncoordinated internal chemical components, poor technical operability, etc., and achieves convenient access, coordinated and reduced chemical components of tobacco leaves. The effect of the number of smears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] When the flowering number of the flue-cured tobacco variety Honghua Dajinyuan reaches 50%, cover the top fireworks and 3-4 small leaves of the uppermost near-primary inflorescence with blue plastic bags to ensure that the number of effective leaves of the tobacco plant is about 22.

Embodiment 2

[0025] When the flowering number of the flue-cured tobacco variety k326 reaches 55%, cover the fireworks on the top together with the three small leaves of the uppermost near-primary inflorescence with a black plastic bag to ensure that the number of effective leaves of the tobacco plant is 20-22.

Embodiment 3

[0027] For the flue-cured tobacco variety Bina No. 1 in Guizhou, when the flowering number reaches 60%, cover the top fireworks and the 5 small leaves of the uppermost near-primary inflorescence with a blue plastic bag to ensure that the number of effective leaves of the tobacco plant is 22-24 piece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com