Grain drying and storing warehouse

A grain drying and warehouse technology, applied in fruit hanging devices, botany equipment and methods, horticulture, etc., can solve the problems of easy mildew of grain, and achieve the effects of preventing damp mildew, ensuring ventilation, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

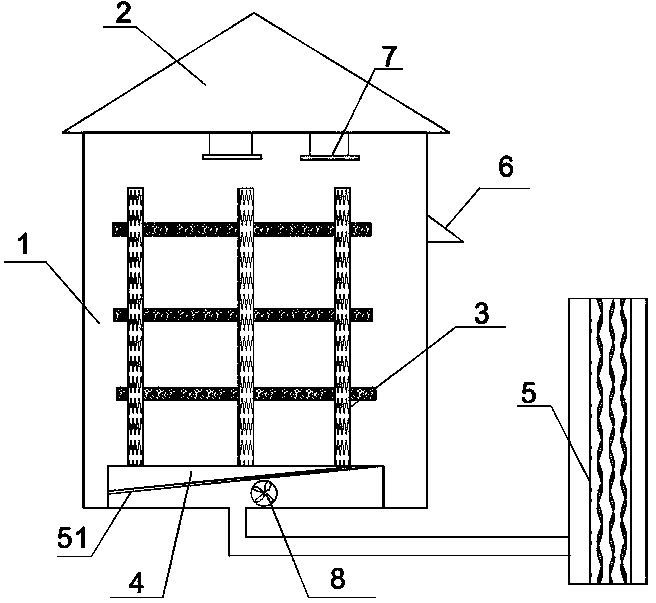

[0016] like figure 1 As shown, a grain drying storage warehouse includes a warehouse composed of a wall 1 and a ceiling 2. The warehouse is provided with a grid partition wall 3 composed of vertical partitions and horizontal partitions. The vertical partitions Both the vertical and horizontal partitions are hollow plates composed of double-layer grids, and the inner cavities of the vertical partitions and the horizontal partitions are connected to the air source heat pump 5 through the air duct 4, and the air source heat pump 5 includes sequentially connected A compressor, a condenser 51, a liquid accumulator, a drying filter, a throttle valve, an evaporator, a gas-liquid separator, a closed circulation system formed by the communication between the gas-liquid separator and the compressor, the condenser 51 is arranged in A fan 8 is arranged in and inside the air duct 4 .

[0017] The hot air is generated by the air source heat pump, and the hot air is blown into the grid part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com