Rack storage system and method for operating same

A storage system and shelf technology, applied in transportation, packaging, storage devices, etc., can solve the problems of high investment cost, complex structure of shelf storage system, cost of control technology, etc., and achieve the effect of high throughput capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

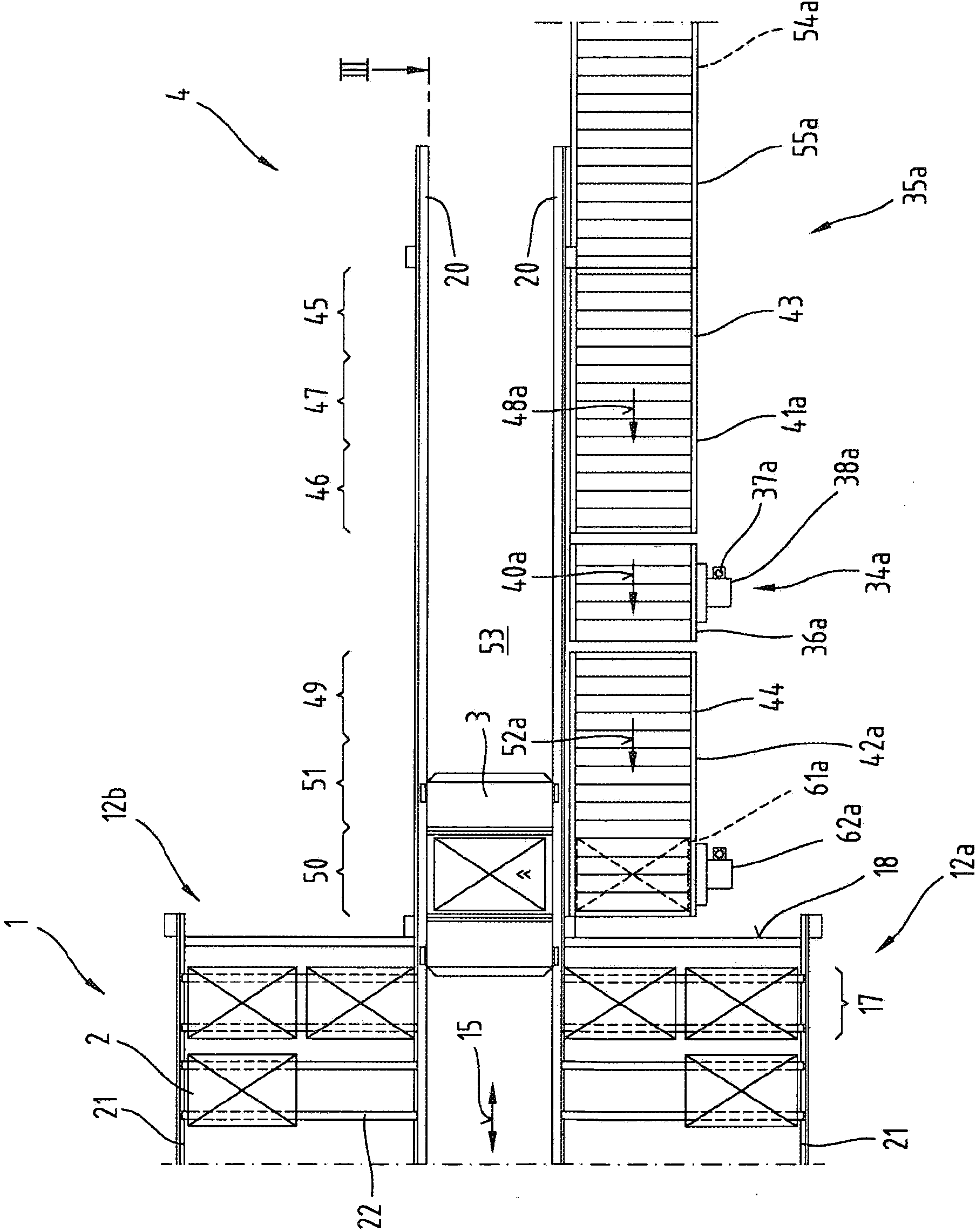

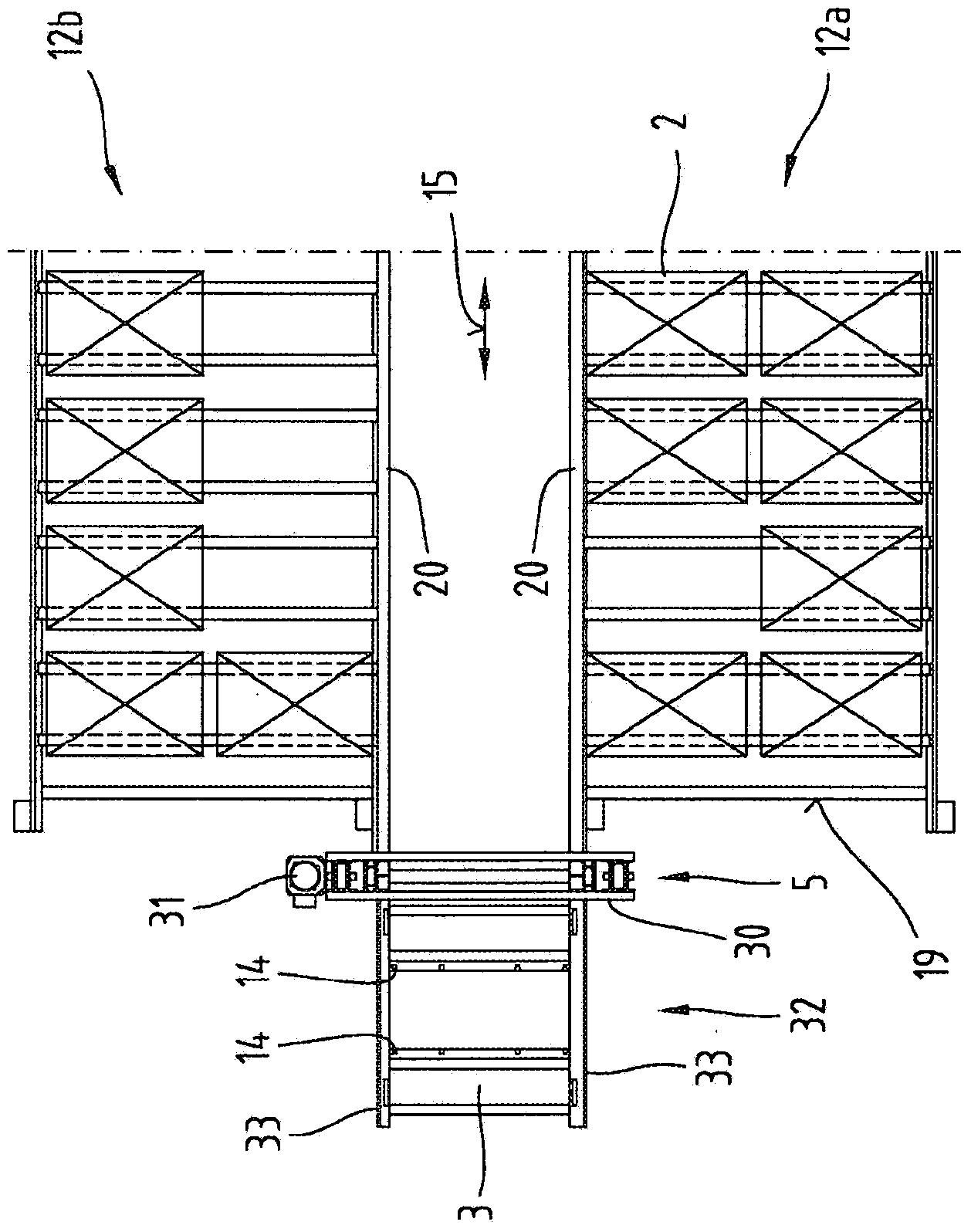

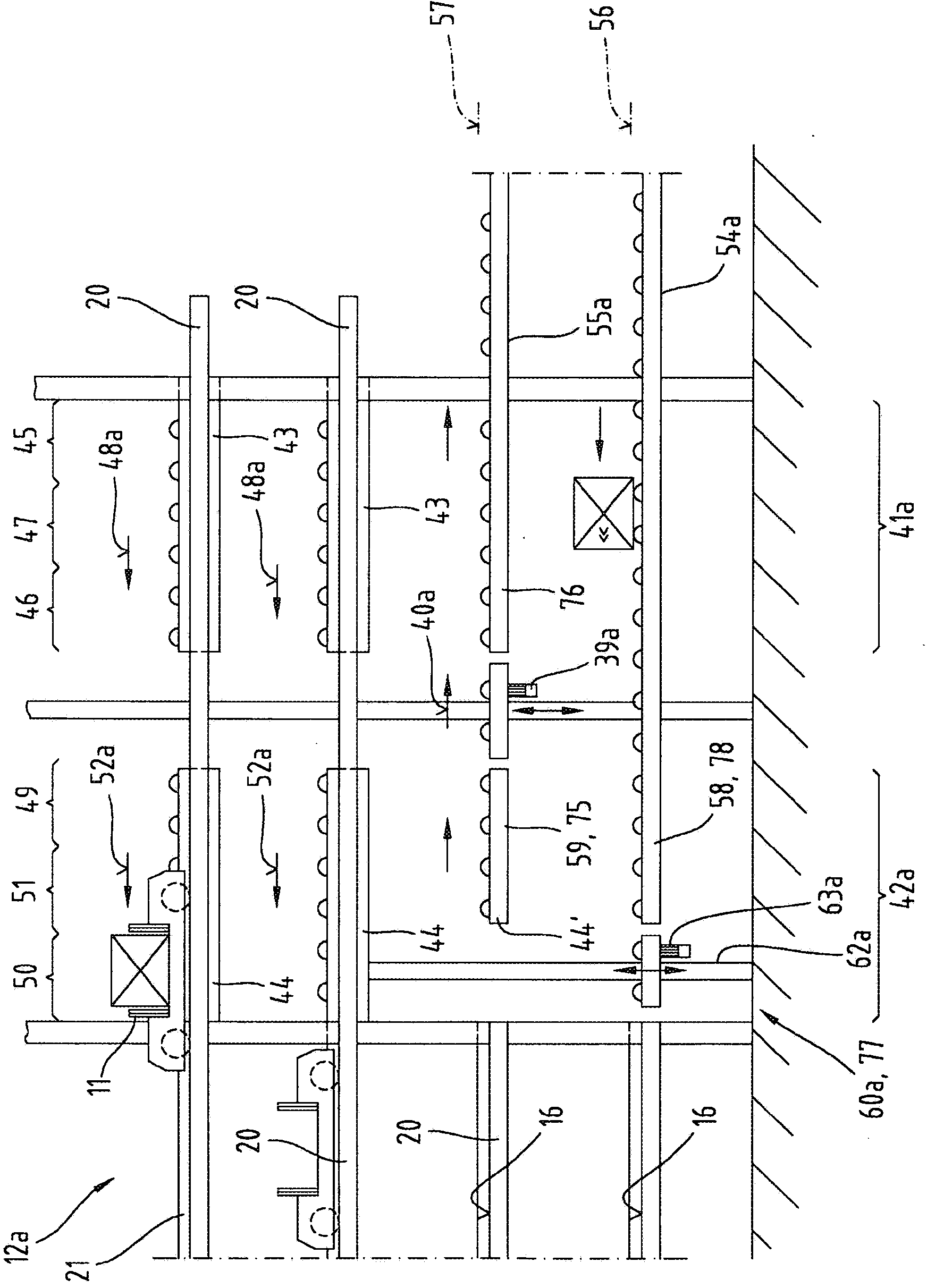

[0074] First of all, it should be noted that in the differently described embodiments, the same parts have the same reference signs or the same component names, wherein the disclosure content included in the entire description can be transferred reasonably to the same reference signs or components. On the same part with the same component name. Positional indications selected in the description, such as eg top, bottom, side, etc., also refer to the currently described and illustrated figures and can be transferred to the new position as appropriate in the event of a position change. It should also be pointed out that only a few shelf planes 16 are shown in the figures for better clarity. The shelf storage system described below generally has between 15 and 25 shelf planes.

[0075] exist Figures 1 to 5 The first embodiment of the rack storage system is shown in the figure, and the rack storage system includes a rack warehouse 1 for loading goods 2, at least one self-propell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com