Heat dissipating system for current transformer

A heat dissipation system and converter technology, applied in the direction of output power conversion device, cooling/ventilation/heating transformation, electrical components, etc., can solve the problem of waste of cooling medium, to solve condensation, improve equipment stability, prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

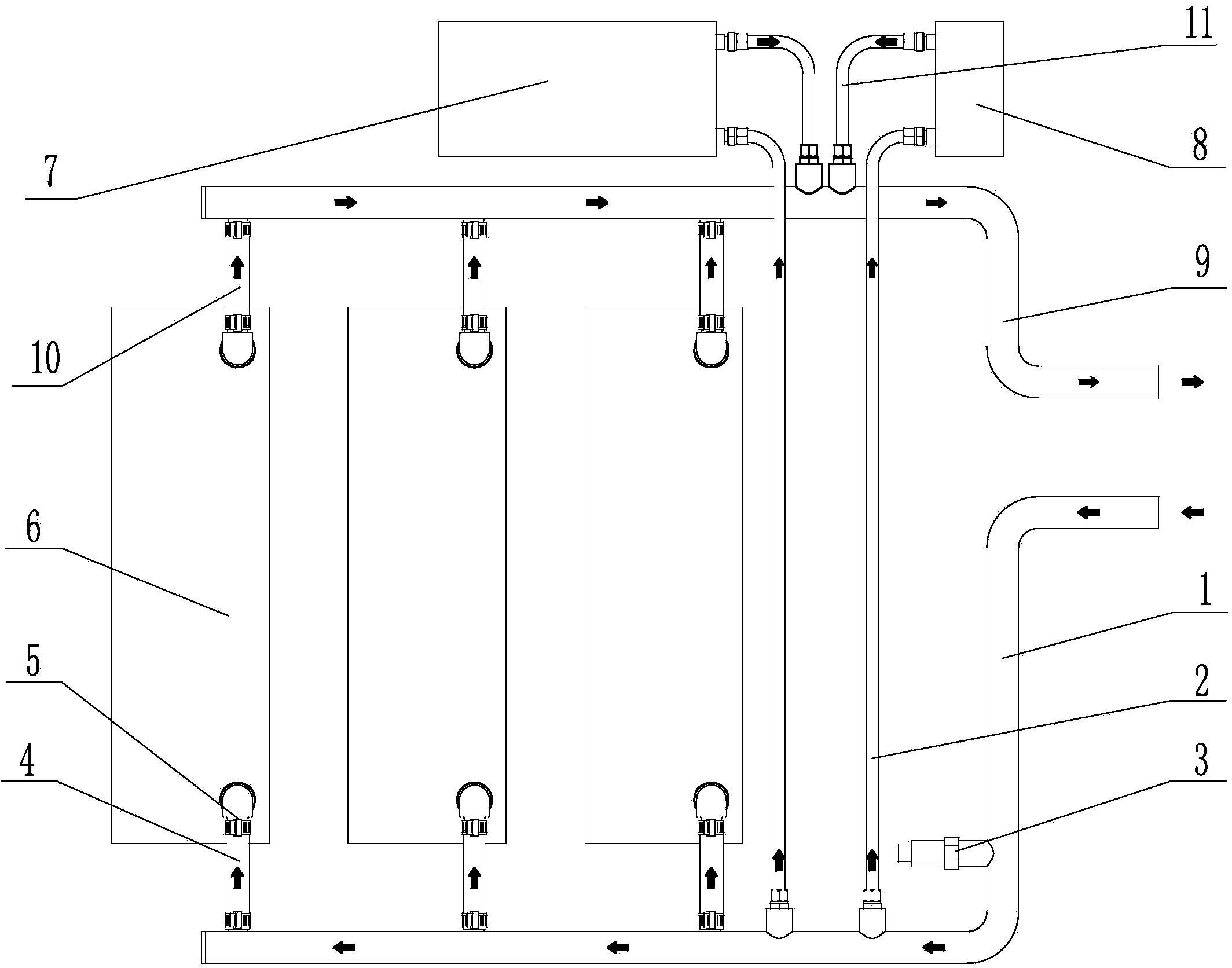

[0023] Such as figure 1 Shown is a specific embodiment of the heat dissipation system of the converter of the present invention. In this embodiment, the heat dissipation system mainly includes a main water inlet pipe 1 connected to a cooling water source, a large-diameter water inlet pipe 4 connected between the main water inlet pipe 1 and a high-power heat dissipation device 6; The small-diameter water inlet pipe 2 between the power cooling devices 7; and the water outlet pipe 9. Among them, the outlet pipe 9 is connected to the outlet of the high-power heat dissipation device 6 through the branch pipeline 10, and the outlet pipe 9 is connected to the outlet of the low-power heat dissipation device 7 through the branch pipeline 11, and then the fluid medium carries heat and is discharged from the outlet of the outlet pipe 9. device. Here, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com