Particle board resonance sound absorption structure

A technology of resonant sound absorption and particle board, which is applied in the direction of sound-generating devices and instruments, can solve the problems of inconvenient cleaning, etc., and achieve the effects of low cost, wide sound absorption frequency band, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

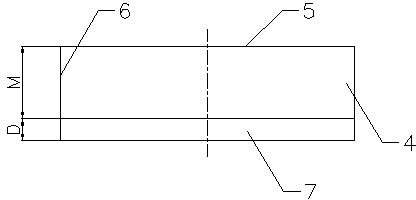

Embodiment 1

[0064] Select 20-24 mesh particles to make a 10mm particle sound-absorbing board, the particle size range is 0.8-0.9mm, the diameter of the micro-voids is about 0.182-0.2mm, and the porosity is about 25%, and then a cavity 4 is set. The depth M=40mm. The sound-absorbing structure parameters of the micro-perforated plate in comparison are: plate thickness D=10mm, perforation diameter 0.8mm, perforation rate 25%, and cavity depth 50mm.

[0065] Its sound absorption properties are Image 6 It can be seen that the measured performance of the resonant sound-absorbing structure of the particle board is consistent with the theoretical sound-absorbing characteristics of the micro-perforated plate sound-absorbing structure with the same parameters. The difference is that the depth of the cavity is different. , the micro-hole is not a straight line, it is curved and turned, which is equivalent to increasing the depth of the cavity behind it, and the increase is about 10mm obtained thro...

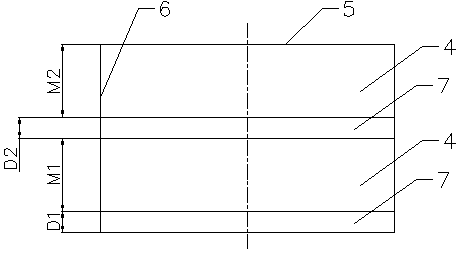

Embodiment 2

[0067] Select 24-40 mesh particles to make a 10mm particle sound-absorbing panel, the particle size range is 0.5-0.8mm, the diameter of the micro-voids is about 0.12-0.182mm, and the porosity is about 25%, and then a cavity 4 is set. The depth M=40mm. The sound-absorbing structure parameters of the micro-perforated plate in comparison are: plate thickness of 10 mm, perforation diameter of 0.15 mm, perforation rate of 25%, and cavity depth of 50 mm.

[0068] Its sound absorption properties are Figure 7 It can be seen that the measured performance of the resonant sound-absorbing structure of the particle board is consistent with the theoretical sound-absorbing performance of the micro-perforated plate sound-absorbing structure with the same parameters. The difference is that the depth of the cavity is different. In the board, the micro-hole is not a straight line, it is curved and turned, which is equivalent to increasing the depth of the cavity behind it, and the increase is ...

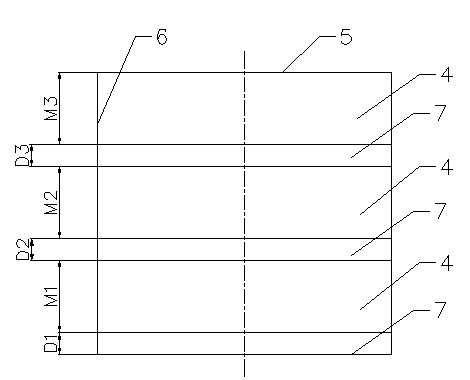

Embodiment 3

[0070] Select 40-50 mesh particles to make a 10mm particle sound-absorbing panel, the particle size range is 0.37-0.5mm, the diameter of the micro-voids is about 0.09-0.12mm, and the porosity is about 25%, followed by a closed cavity. The depth is 40mm. The sound-absorbing structure parameters of the micro-perforated plate in comparison are: plate thickness of 10 mm, perforation diameter of 0.12 mm, perforation rate of 25%, and cavity depth of 50 mm.

[0071] Its sound absorption properties are Figure 8 It can be seen that the measured performance of the resonant sound-absorbing structure of the particle board is consistent with the theoretical sound-absorbing performance of the micro-perforated plate sound-absorbing structure with the same parameters. The difference is that the depth of the cavity is different. In the board, the micro-hole is not a straight line, it is curved and turned, which is equivalent to increasing the depth of the cavity behind it, and the increase i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com