A main nozzle of an air-jet loom with continuously adjustable intake rotation and intake flow

A technology of air intake flow and air-jet looms, which is applied in looms, textiles, textiles, and papermaking. It can solve problems such as large internal stress, difficult shrinkage, and inability to successfully complete weaving, and achieve good mechanical properties and excellent mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

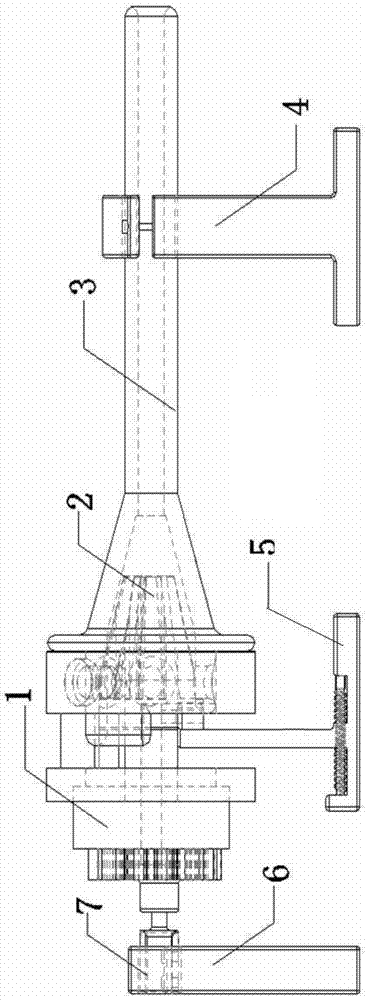

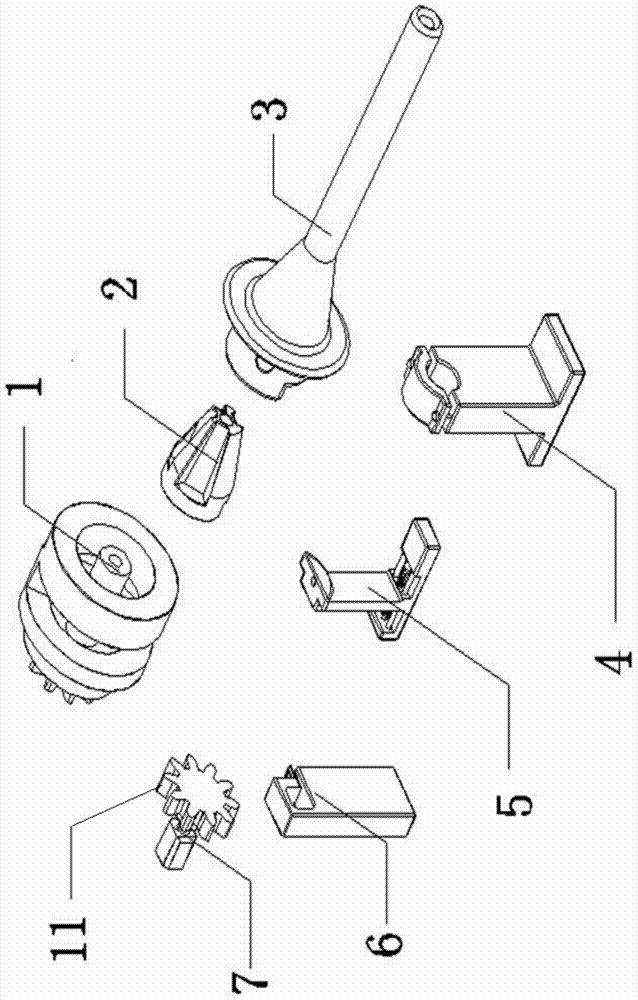

[0018] Please refer to the attached figure 1 To attach Figure 6 As shown, the present invention is a main nozzle of an air-jet loom with continuously adjustable air intake rotation and air intake flow rate, which consists of an air intake rotatable ring 1, a nozzle core 2, a nozzle housing 3, a nozzle bracket 4, a position adjustment Several parts such as motor 5, dispatching motor support 6 and dispatching motor 7 are formed.

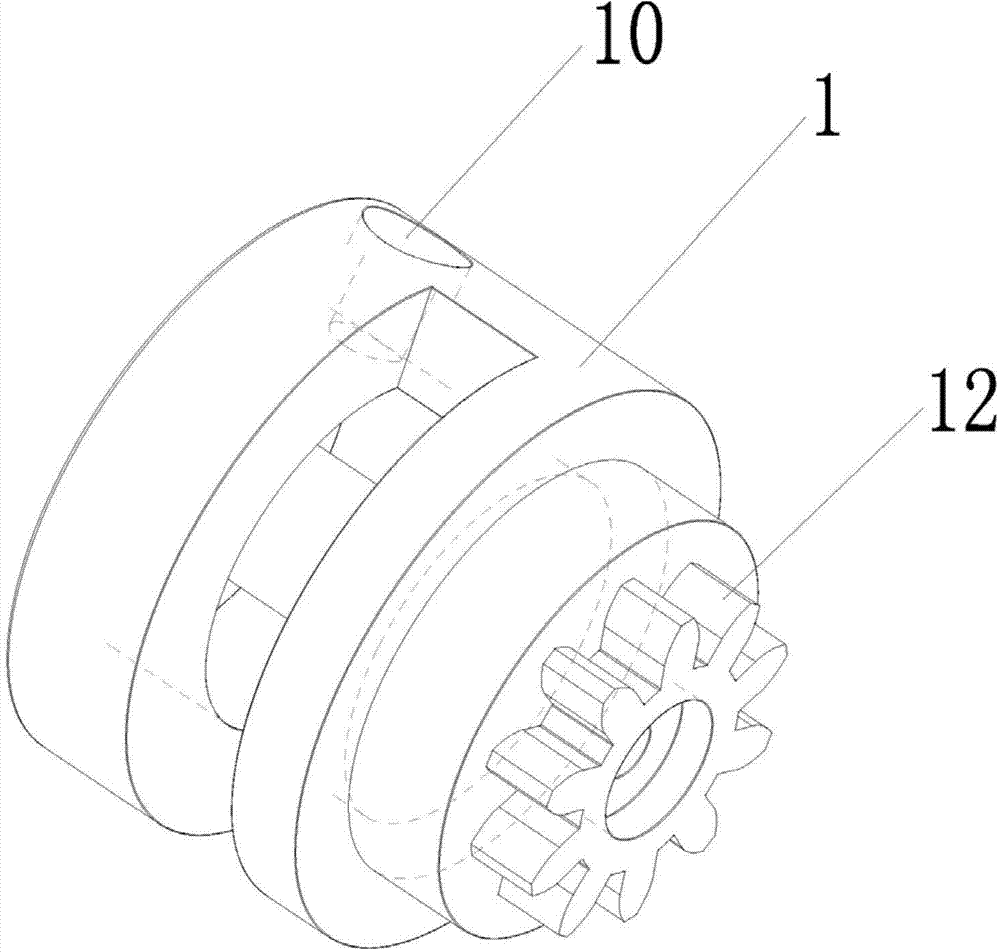

[0019] Wherein, the air intake rotatable ring 1 is in contact with the nozzle housing 3, and an air intake channel 10 is arranged on it.

[0020] The nozzle core 2 is located between the air intake rotatable ring 1 and the nozzle housing 2, and is provided with four air intake channels 13. The position adjustment of the air intake channels 13 is based on the twist direction of the yarn, the direction of the yarn Characteristic, finally determine the input digital signal for automatic position adjustment.

[0021] The nozzle housing 3 is supported o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com