Vibration feeding sterile capsule screening machine

A vibrating feeding and screening machine technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of quality defects, such as the stability of capsule fitting machine fitting, not fitting, etc., to reduce production costs, improve quality, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

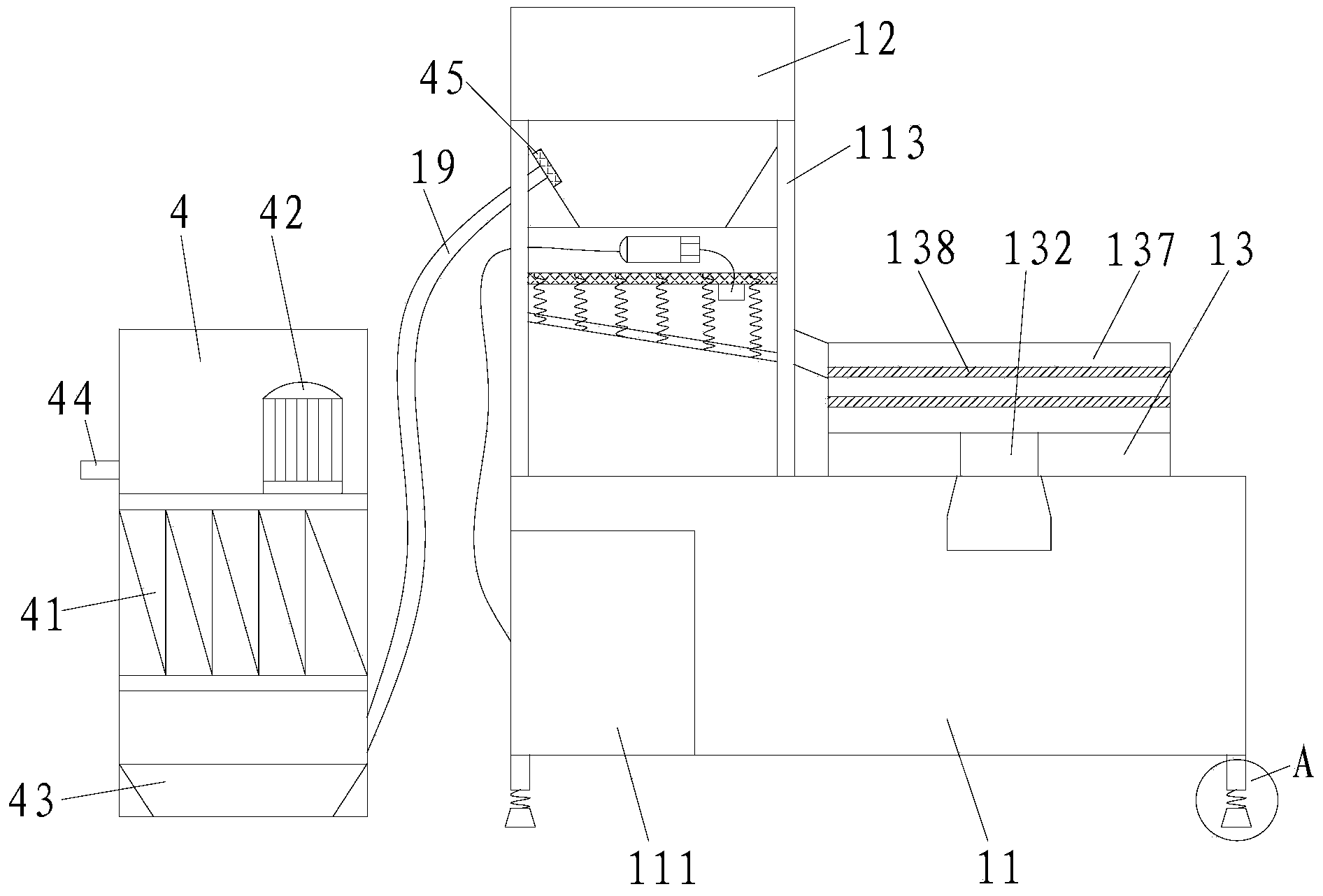

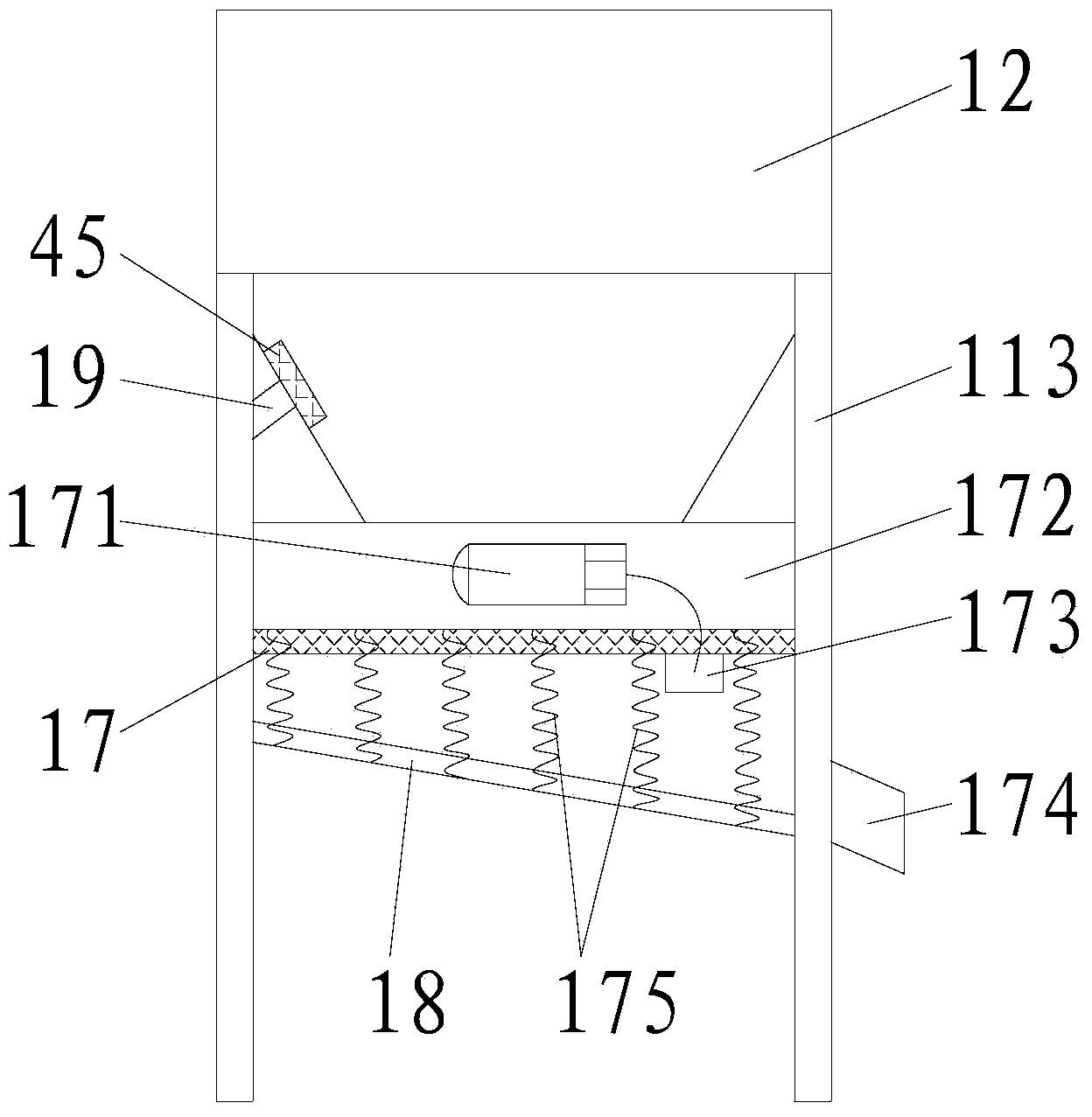

[0022] refer to Figure 1 to Figure 8 , a vibrating feeding aseptic capsule screening machine of the present invention comprises a feeding device 1, a dust removal device 4, a lifting mechanism 2 and a screening device 6, and the feeding device 1 includes a fuselage 11, a support rod 113, a feeding box 12. Mesh screen 17, discharge plate 18, discharge tray 13, a control box 111 is installed in the fuselage 11, the support rod 113 is installed on the fuselage 11, and the support rod 113 is sequentially installed with Feed box 12, mesh screen 17 and discharge plate 18, described mesh screen 17 is equipped with vibration motor 171, vibration motor 171 is connected with control box 111, mesh screen 17 is connected with discharge plate 18 by vibrating spring 175 , the discharge plate 18 is connected to the discharge tray 13 through the first discharge port 174, a number of scrapers 131 are installed in the discharge tray 13, a rotating shaft 133 is installed in the center of the di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com