Corrosion resistant alloy plate blank dissecting and analyzing method

A technology of corrosion-resistant alloy and analysis method, which is applied in the field of anatomical analysis for inspecting the internal quality of electroslag remelting corrosion-resistant alloy slab, can solve the problems of material waste, high price, inspection of rolling performance of electroslag slab, etc. Save expensive materials, the effect of scientific analysis methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with embodiment:

[0036] The present invention dissects and analyzes UNS S32760 duplex stainless steel electroslag remelting slabs whose thickness, width and length are 200mm, 1250mm and 4000mm respectively, and the method is also applicable to other duplex stainless steels, super austenitic stainless steels, iron-nickel stainless steels Electroslag remelting slabs such as corrosion-resistant alloys and nickel-based corrosion-resistant alloys, the specific methods are as follows:

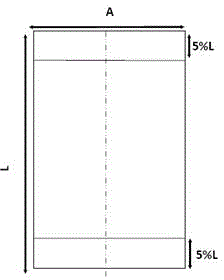

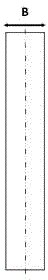

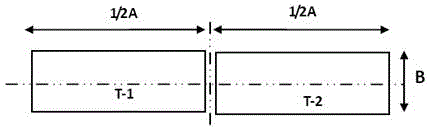

[0037] (1) if figure 1 , figure 2 As shown, define the length of the electroslag slab as L, the width of the slab as A, and the thickness of the slab as B, and saw off the head and tail of the electroslag slab along the length direction of the electroslag slab 5% of the length, as the test material, the test sample number of the head of the electroslag slab is T, the test sample number of the tail of the electroslag slab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com