Counter type boiler

A container-type boiler technology, which is applied in the field of boilers and container-type boilers, can solve the problems of inconvenient climbing for staff, and achieve the effects of labor-saving climbing, easy climbing, and good guiding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

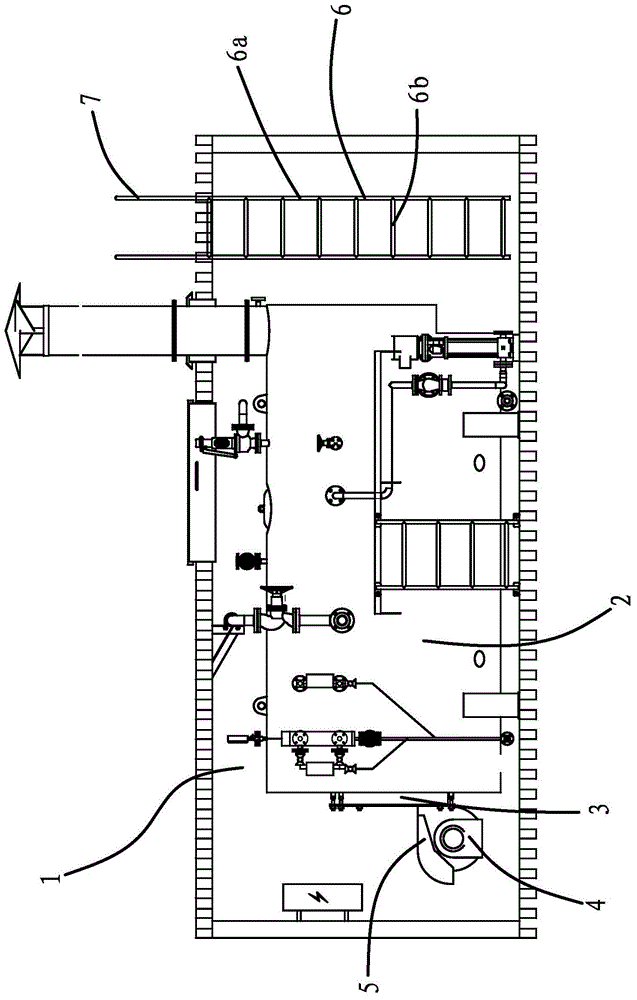

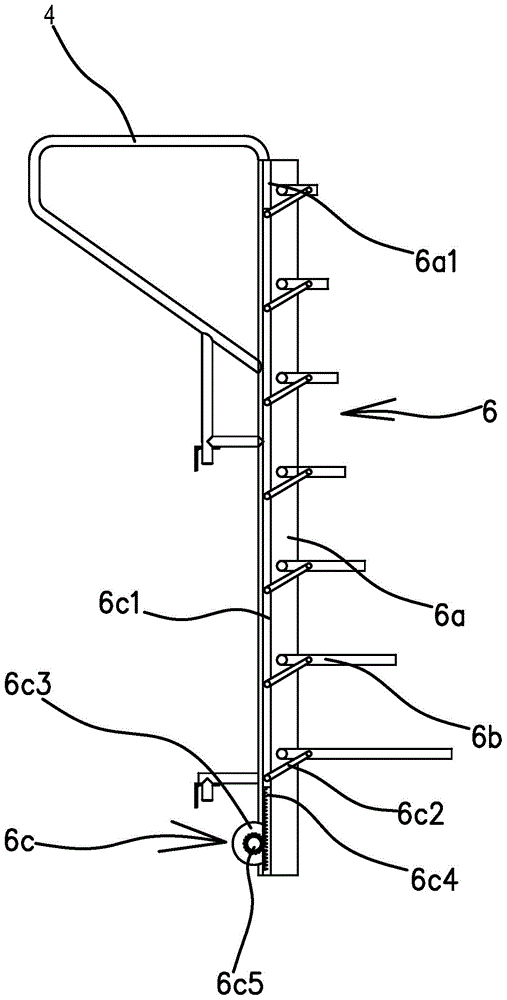

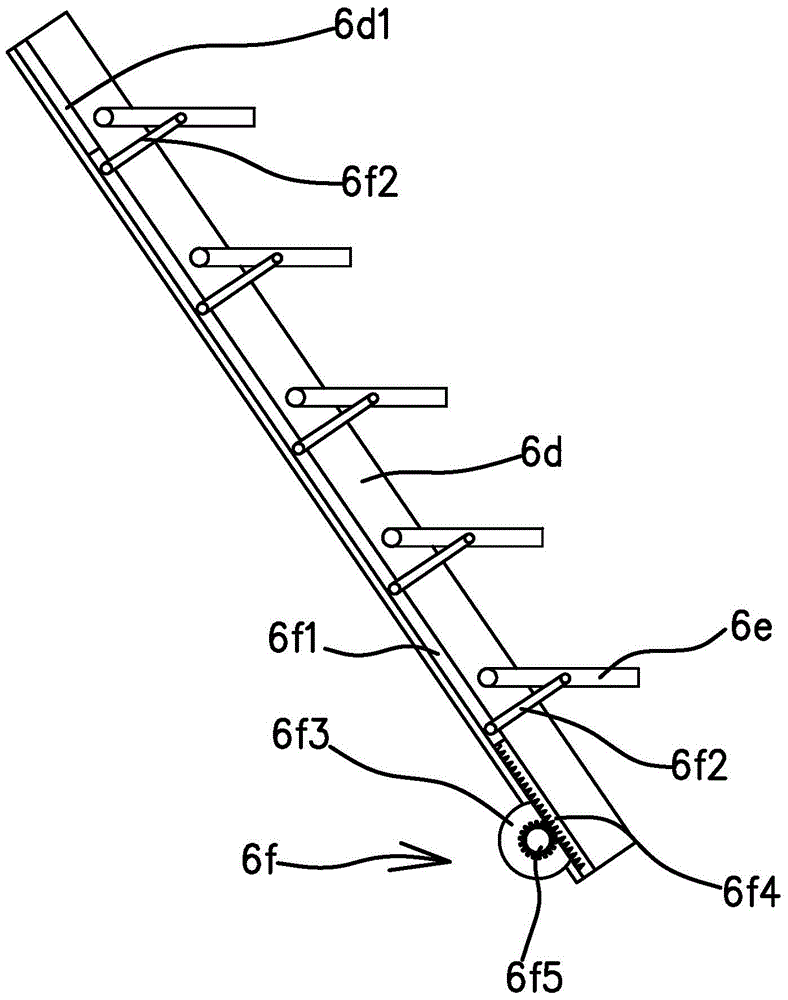

[0027] Such as Figures 1 to 4 As shown, the container-type boiler includes a box-shaped cabinet body 1, and a boiler body 2 is fixedly connected to the cabinet body 1. The boiler body 2 includes a cylindrical furnace 3, and the burner fixing device on one side of the furnace 3 4. A burner 5 is fixedly connected to the burner fixing device 4, the outlet of the burner 5 is connected with the cavity of the furnace 3, and the outside of the cabinet 1 is fixedly connected with a ladder assembly 6, which includes two parallel There are two upright columns 6a, and several plate-shaped or frame-shaped footsteps 6b are arranged between the two uprights 6a. The two sides of the footsteps 6b are respectively hinged with the correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com