Heat dissipation system and work method thereof

A technology of a heat dissipation system and a heat exchange system, applied in the field of heat dissipation systems, can solve the problems of air-cooled pollution of dust, pollution of the atmosphere, affecting the service life of equipment and the health of workers, etc., and achieves the effect of good heat dissipation effect and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

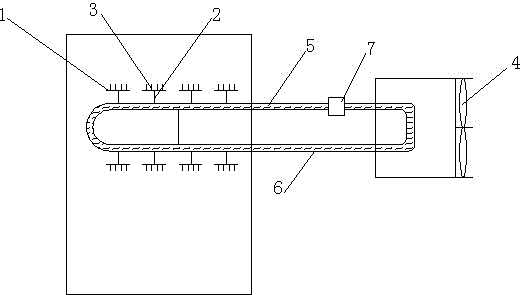

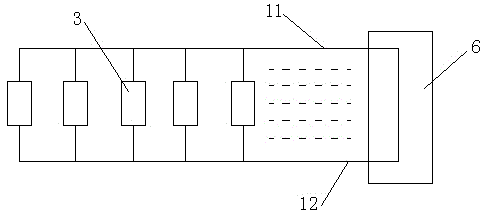

[0032] The present invention is a heat exchange system: it includes a heat dissipation pipe 6 with a refrigerant 5 circulating inside, one part of the heat dissipation pipe 6 is arranged in a space, and the other part protrudes from the space, and the path of the heat dissipation pipe 6 in the space A number of heat collectors 1 are connected to it; a heat dissipation module 4 for heat exchange with the heat dissipation pipe 6 is provided on the path of the heat dissipation pipe 6 outside the space, and a circulation pump 7 is provided on the pipe.

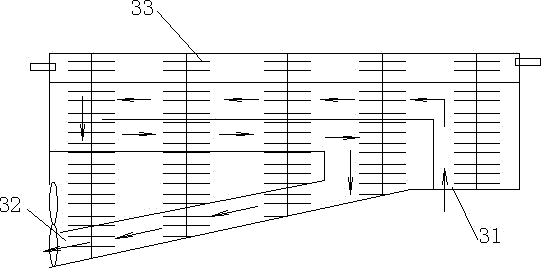

[0033] The heat collector 1 has the following structure: it is formed by parallel connection of several heat collection modules, and each heat collection module is formed by parallel connection of several heat collection single chips 3; the structure formed in each heat collection single chip 3 satisfies: The flow direction is opposite to that of the hot air entering the heat collection sheet 3 in the space, forming reverse contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com